Metal Alloys - FFF vs PAM

Produce with industrial quality material at unbeatable cost.

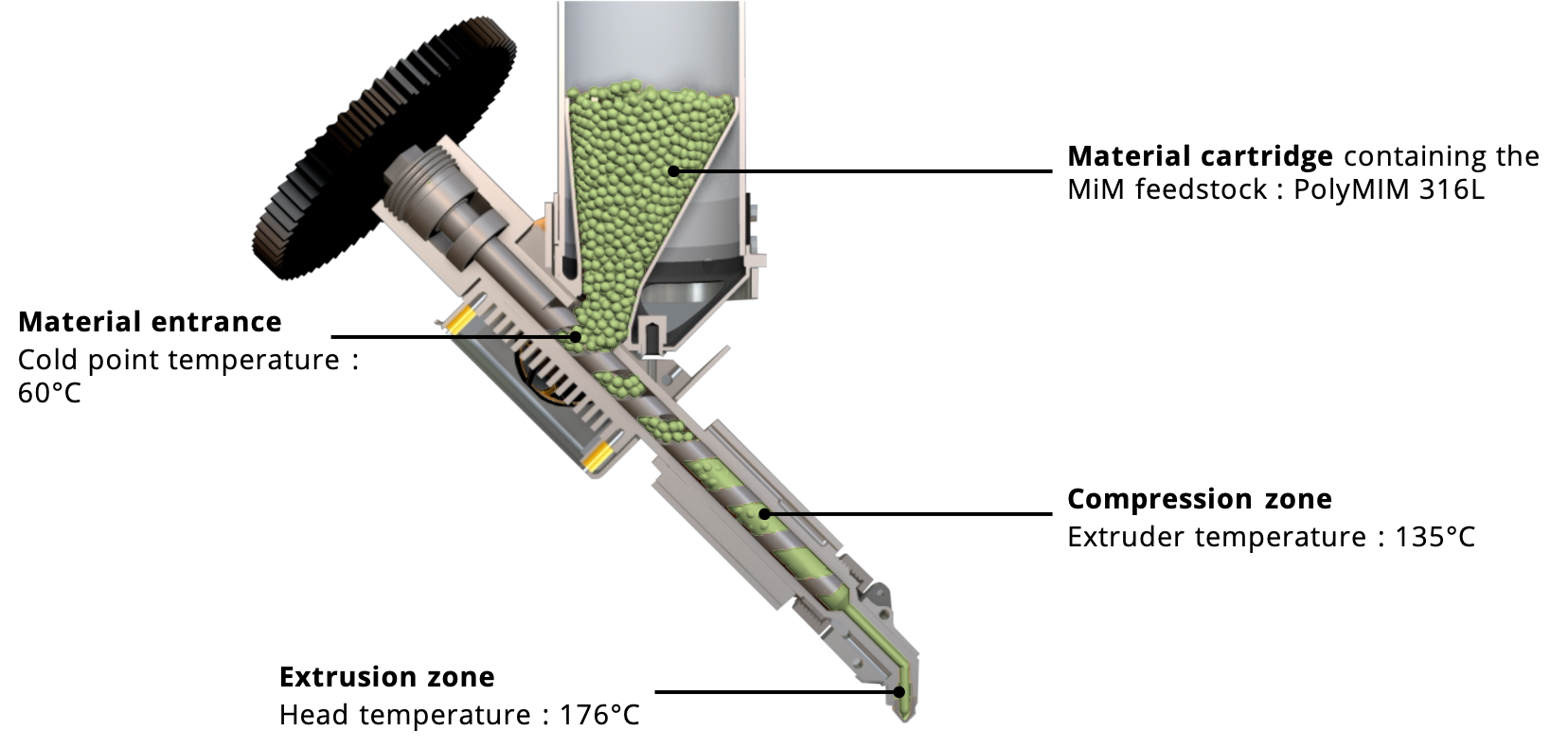

The use of MIM feedstock allows the process of future metal alloy parts at low temperatures. Initially aimed at injection molding, these compounds are compatible with the Pollen AM Pam Series MC 3D printers. Pollen AM recommends Polymim GmbH MIM feedstocks.

Once formed, the parts will undergo a set of chemical and thermal post-treatments to give the parts the correct material properties. ( Debinding / Sintering).

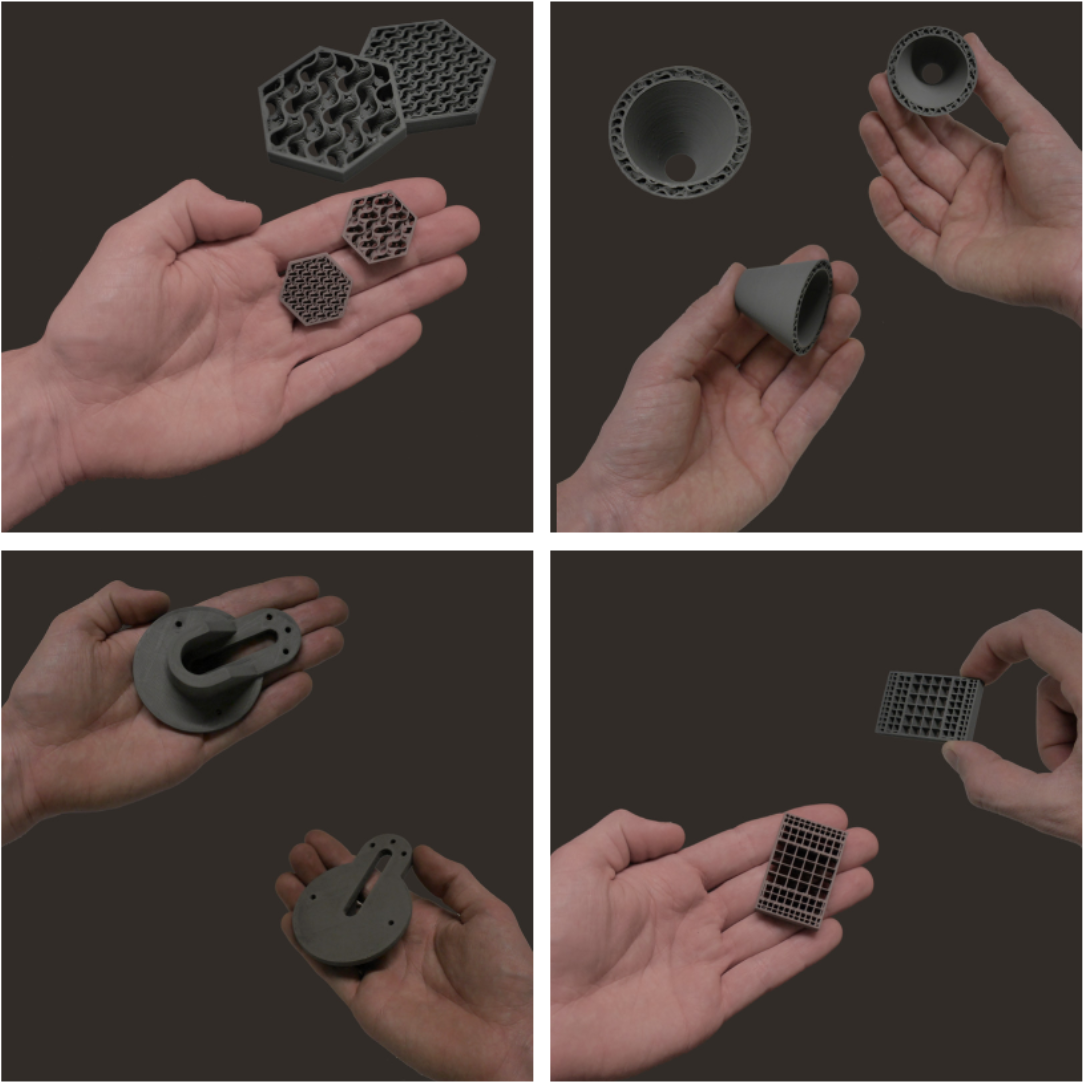

Discover our some productions made with 316L Stainless Steel. These parts were produced using a commercial feedstock produced by the company PolyMIM GmbH, one of the European leaders in the production of MIM feedstocks.

These parts above are captured in their green states, you will soon discover the parts after the sintering process.

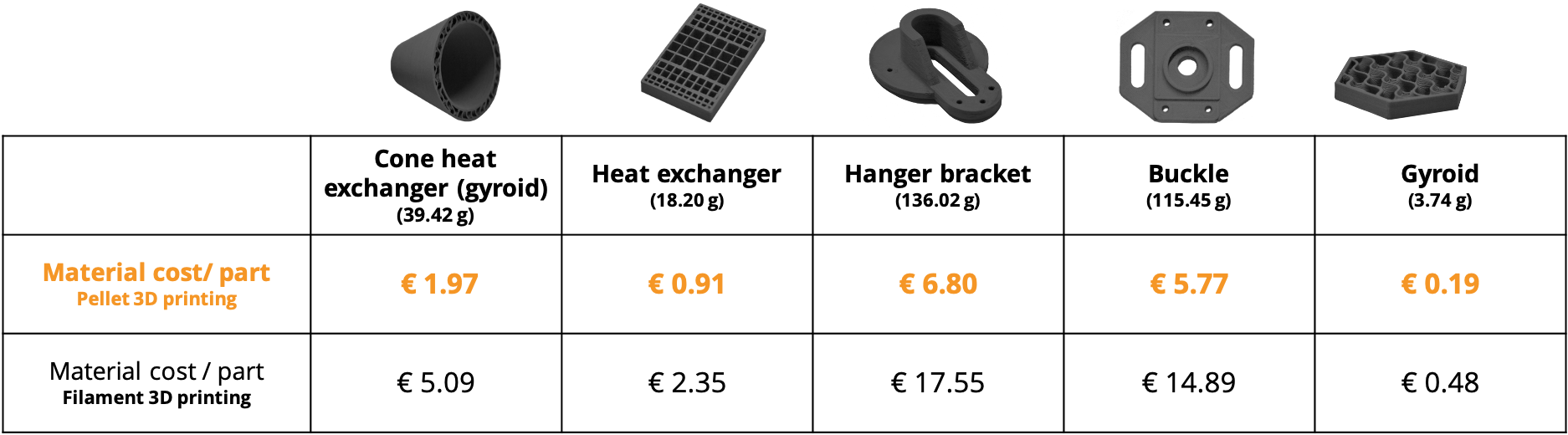

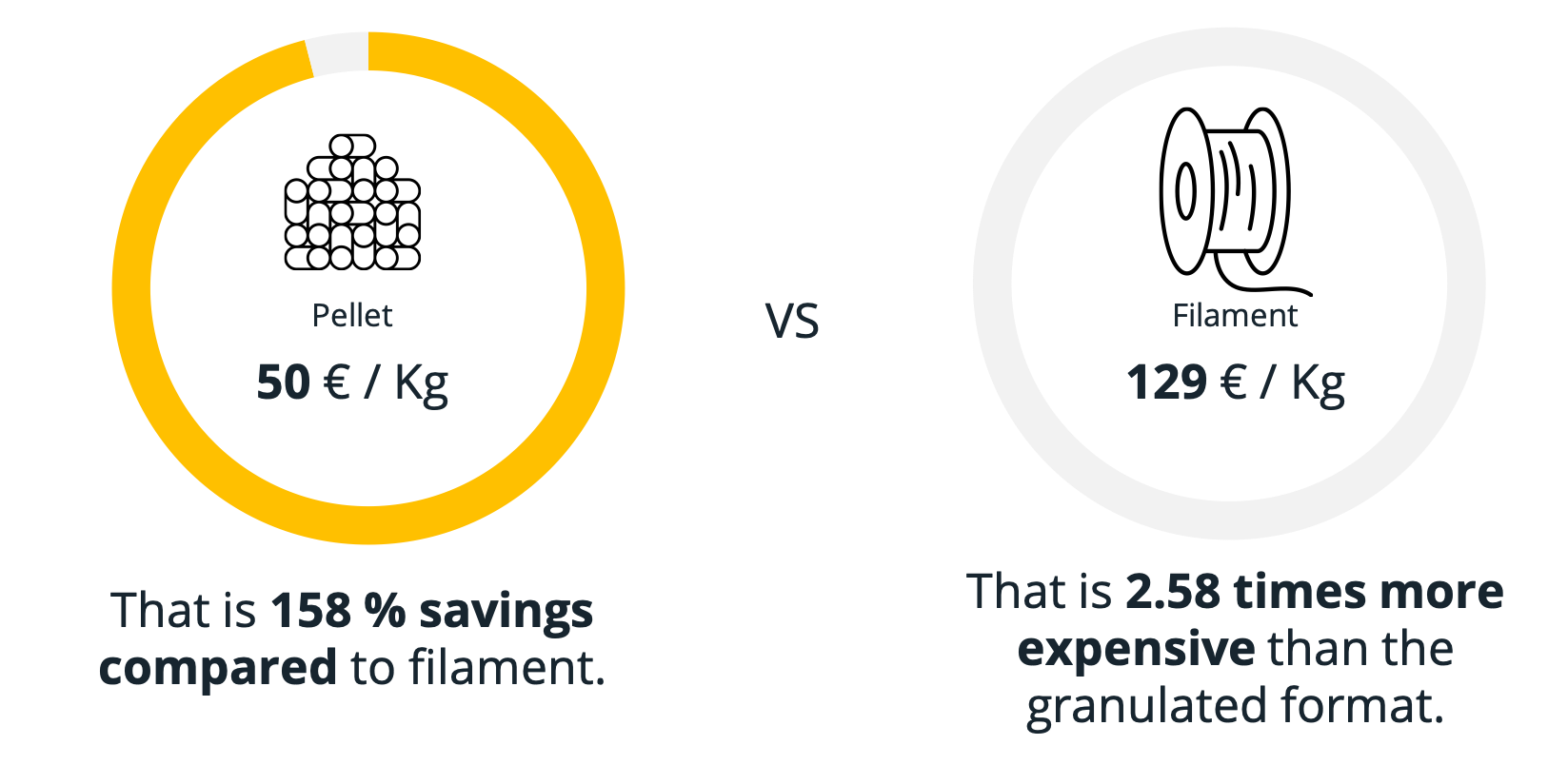

The use of metallic feedstock in the form of pellets allows users of Pam Series MC 3D printers to benefit from a formulation adapted to project needs and at its lowest cost.

The use of industrial compounds in pellet form makes it possible to produce parts at a lower cost, comparable to manufacturing by injection molding, within shorter delays and with no tooling cost.

Considering 3D printing manufacturing, the use of compound in pellets form is the cheapest solution on the market to produce metal parts. (Pam vs. FDM, Binder Jetting, SML)

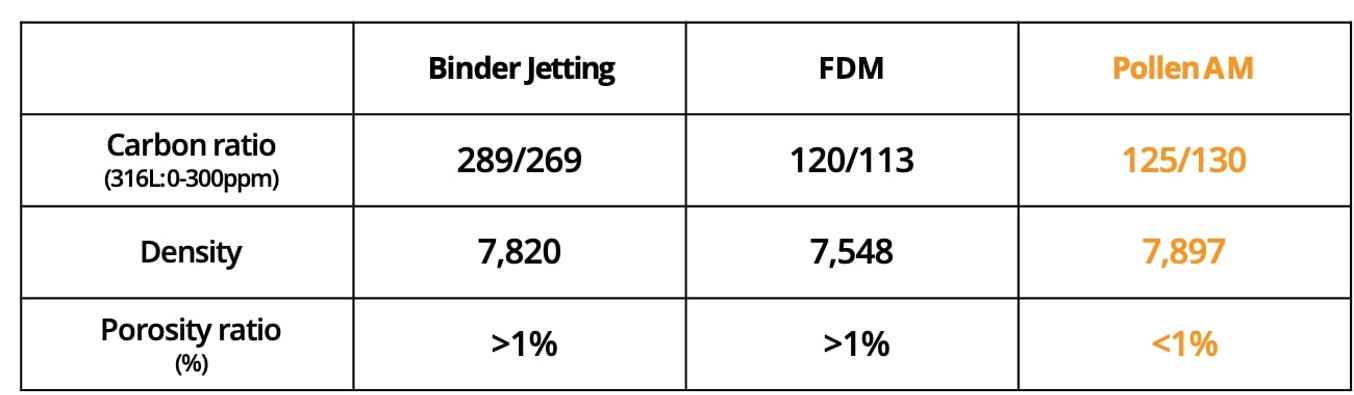

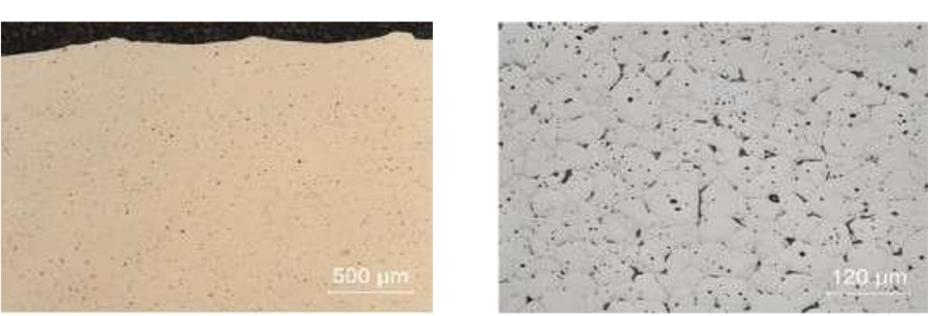

Microscope examination after oxalic acid attack

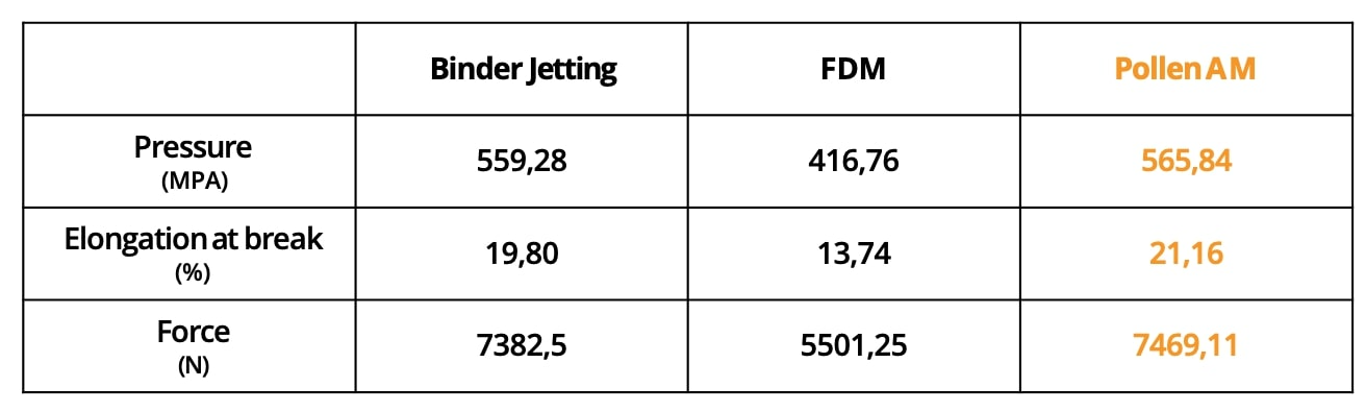

Comparative results of tensile tests

Comparative results of tensile tests

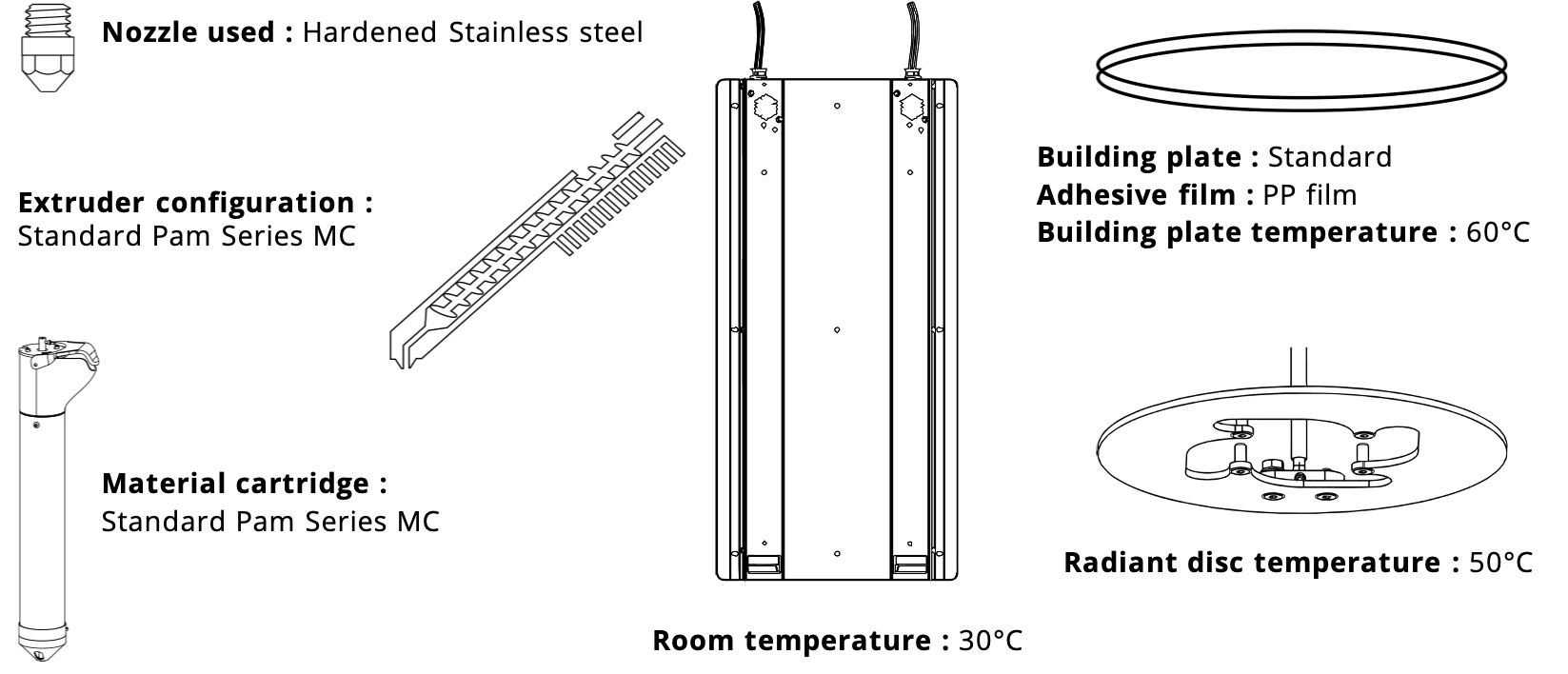

3D Printing parameters

To know more about the 3D printing process, contact our expert team !

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.