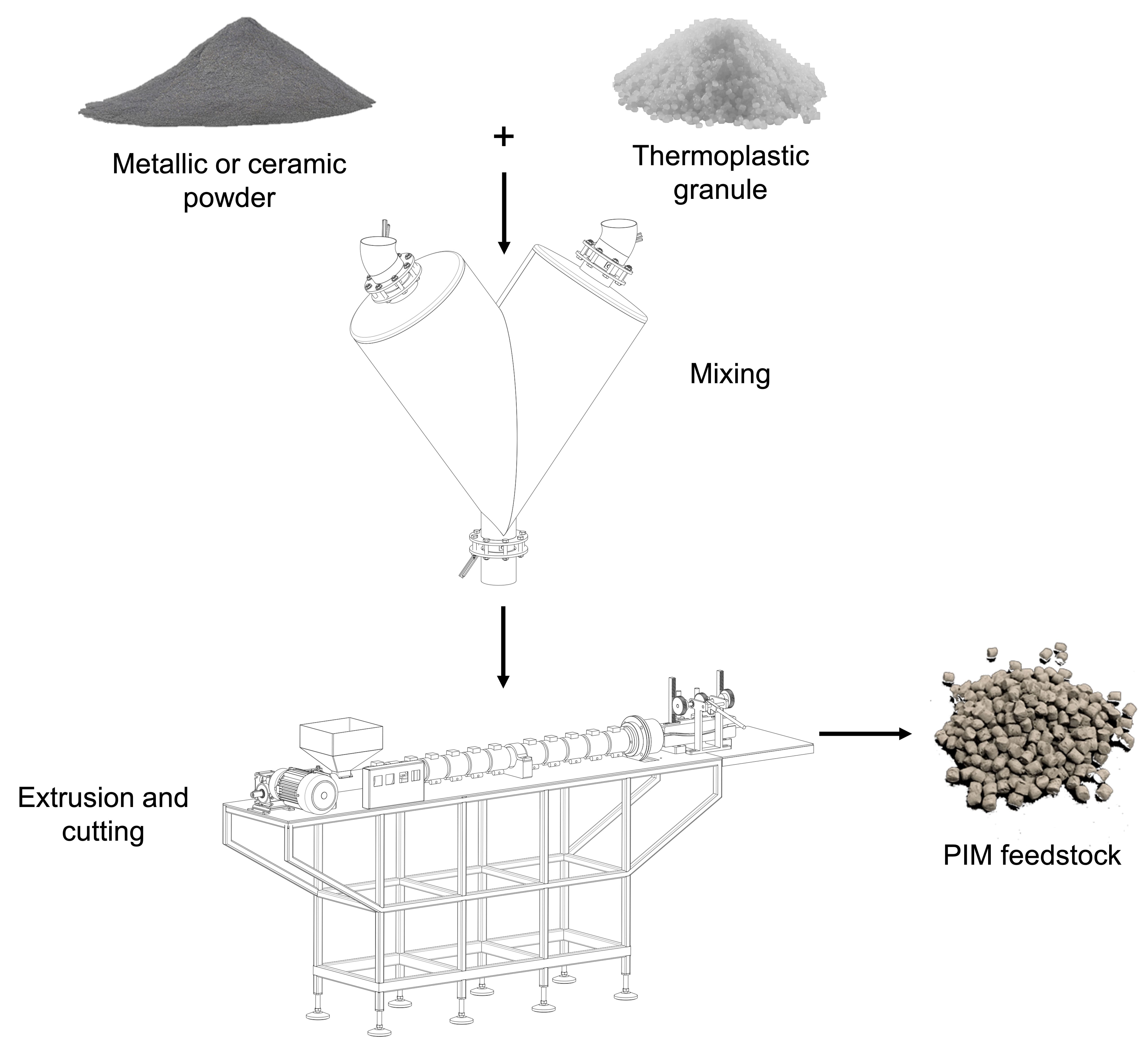

Feedstock fabrication

Giving plastic properties to metal and ceramic powders.

Compared to the forge or the foundry of metal parts, MIM (Metal injection moulding) is very recent, this technique belongs to the family of PIM's (Powder Injection Moulding).

Work was initiated in the United States in the 1920's on ceramic (CIM - Ceramic injection Moulding). The original idea was to plasticize powders, that is, to give them plastic properties by coating them with organic matter. This thermoplastic behavior "composite" is subsequently formed using a press and an injection mould to obtain a more or less complex part.

During the Second World War, work was extended on metallic powder, it was not until the 1970s that industrial applications of the MIM process surfaced.

Discover Metal and Ceramic 3D printed parts