Microscopic observation of PA pellets filled with glass fiber.

Robotic application of a bi-material gripper (ABS - TPE)

with rigid skeleton and soft skin.

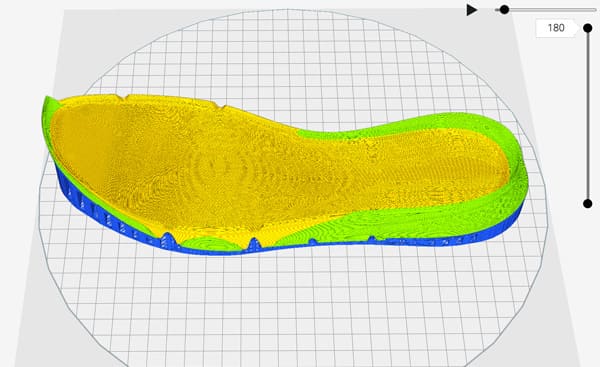

Sportswear application of an oustsole prototyped

with the original materials.

View of outsole sliced with Cura software.

3 materials are required for print job:

2 for elastomers combination and 1 for support structure.

Yellow: TPE 45 ShA - Green: TPE 70 ShA - Blue: HIPS

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.