First layers

Recommendations.

The challenge of this first layer is to ensure an optimal cohesion with the printing plate in order to offer a robust base for the continuation of the printing process.

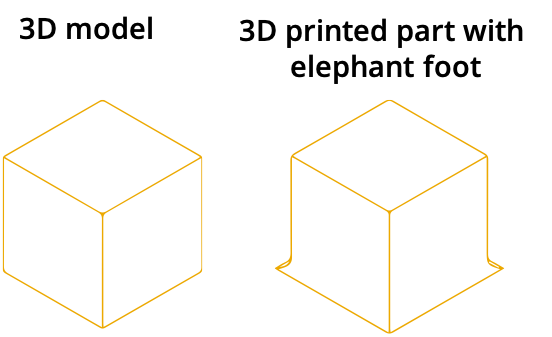

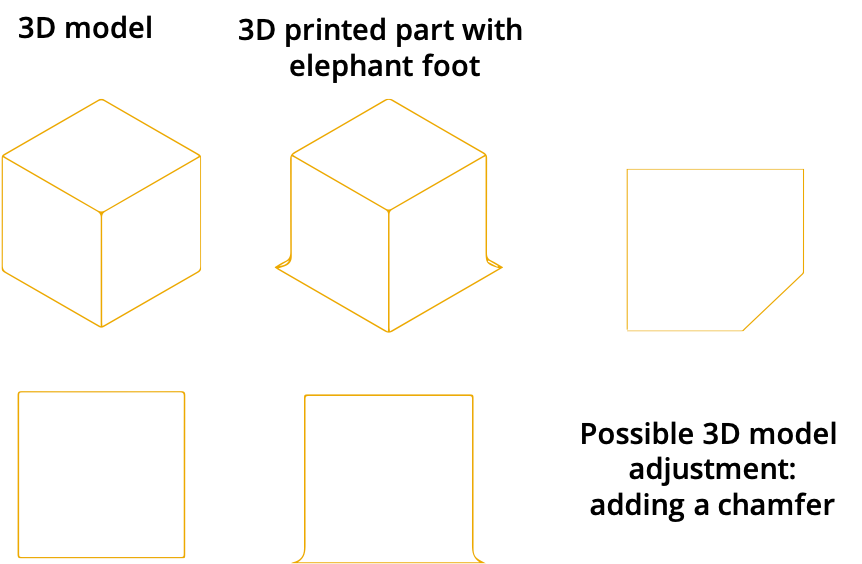

Elephant feet

Good adhesion of the first layer to the build plate is essential. However, sometimes it will end up with a part that has a bulging first layer which is called elephant foot.

This issue is usually the result of poor build plate levelling or print settings. When the material is extruded, the nozzle where it flows is too close to the print surface, expanding the material to the sides. Once the first layers are deposited, this issue disappears.

Elephant foot can ruin a part visually and also functionally, as it reduces the tolerances and makes it impossible to combine it with other components that require high precision.

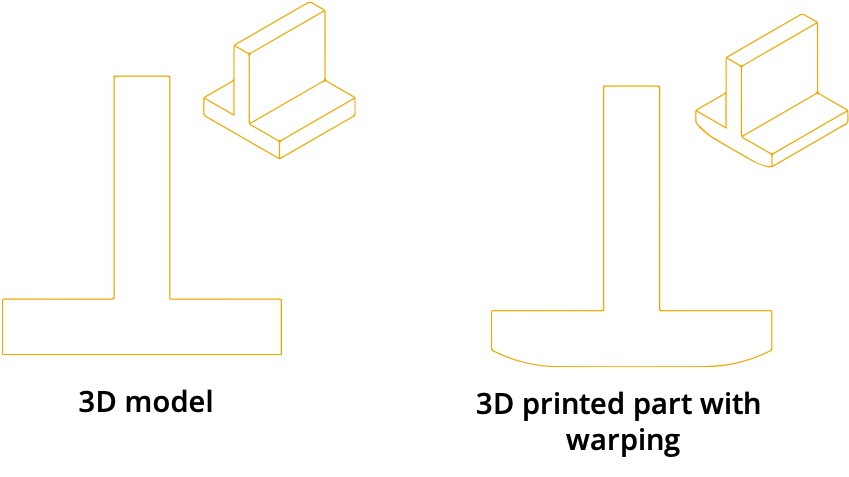

Warping

If elephant foot is a sign of too much adhesion, warping represents the opposite.

When 3D printing large objects, build plate adhesion tends to be difficult and bed levelling and settings really become essential.

It is important to notice that a part has warped when the corners of the bottom part of the 3D model bend upwards.

Some solutions reduce warping include adding rounded corners or by using an optimized build plate substrate.

When modelling, it is recommended to avoid sharp angles and to use rounded corners (if possible in accordance with the diameter of the nozzle used) which present less risk. It is also conceivable to foresee elements to be printed at the corners which reinforce the adhesion to the build plate and will be removed at the end of printing.

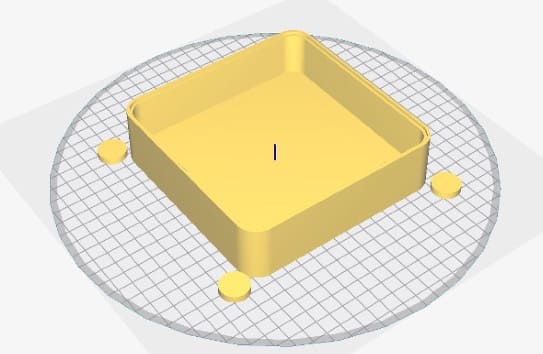

Another solution will be the use of slicing helpers.

Slicing helpers are presented in a separated part.

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.