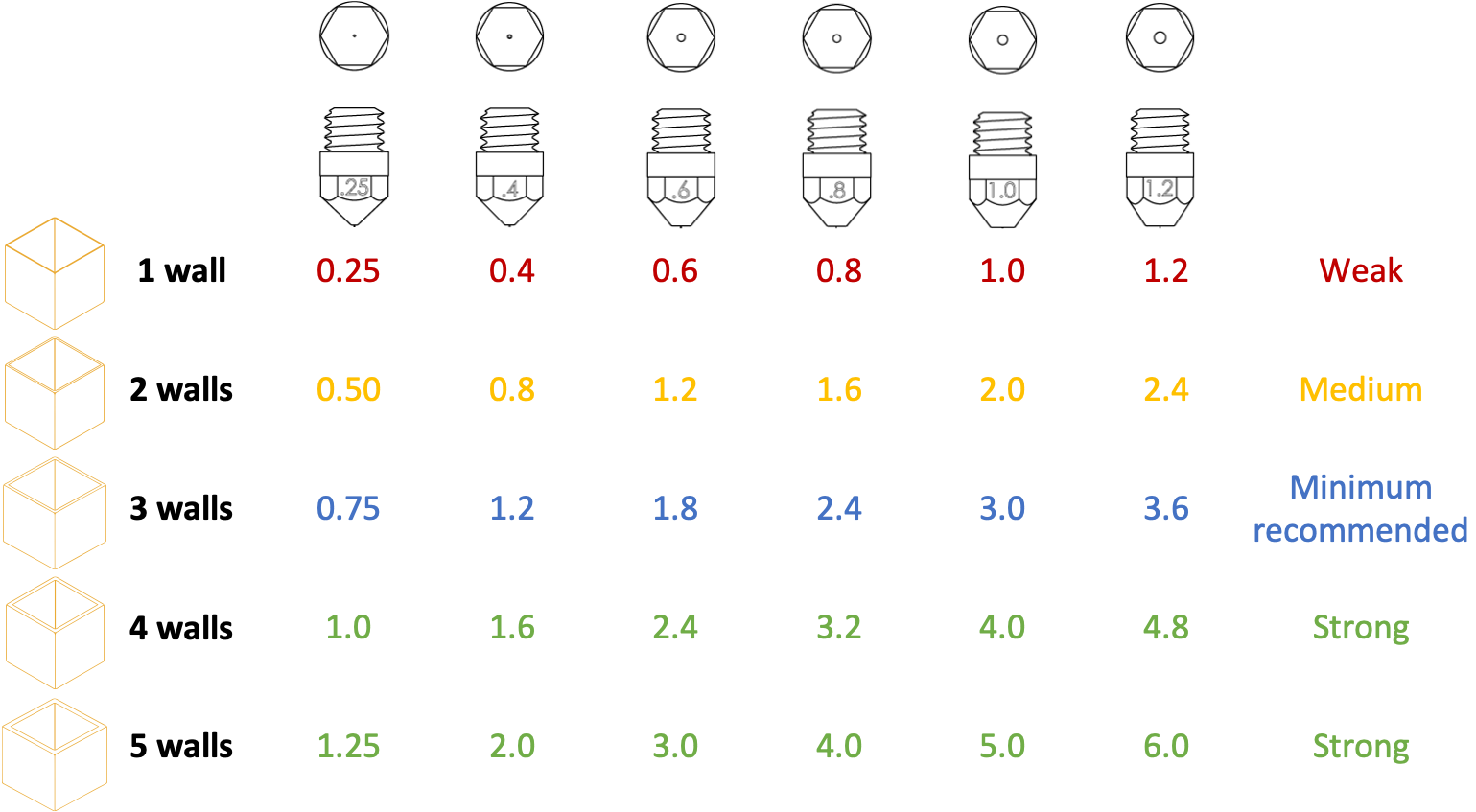

Wall Thickness

Recommendations.

Wall (or skin) corresponds to the outer surface of the 3D printed part; Wall is 3D printed on a number of layers set during the slicing of the part.

It is made by superimposing material and must contain enough layers to ensure the sealing of the outer surface.

Designing an enclosure or the outer shell of a product,it is recommended to consider that the minimum wall thickness for Pam 3D printing is highly related to the nozzle diameter.

The standard nozzle diameter is Ø 0.4 mm and the wall thickness should be at least twice the nozzle diameter.

With a Ø 0.8 mm nozzle, the wall thickness should then be at least 1.6 mm.

In some condition Cura slicing software may ignore thinner walls and they may not be 3D printed although the surface quality and part strength will be reduced.

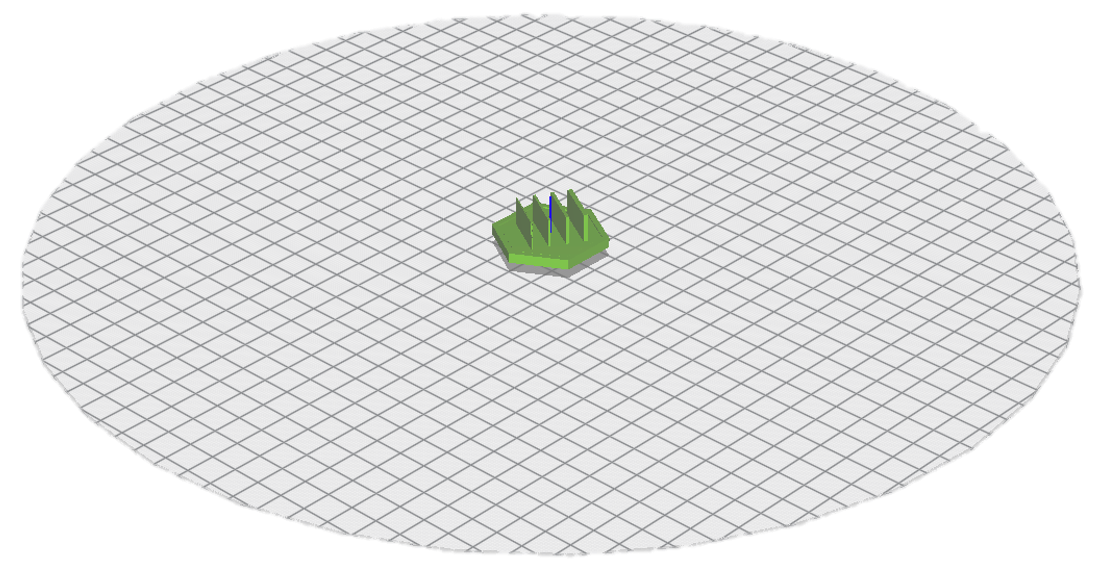

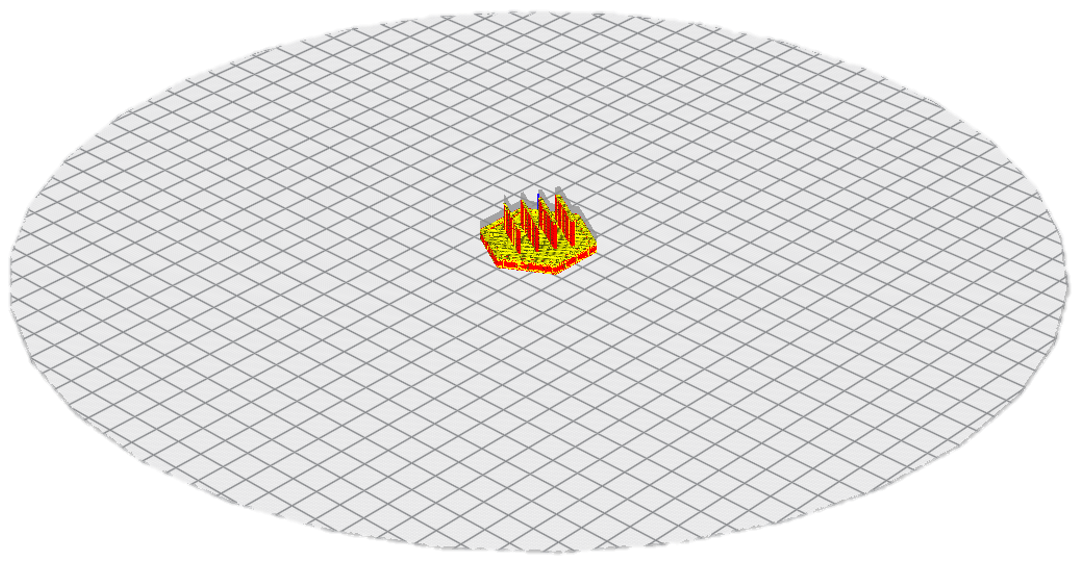

Testing part presentation with 4 different walls thickness.

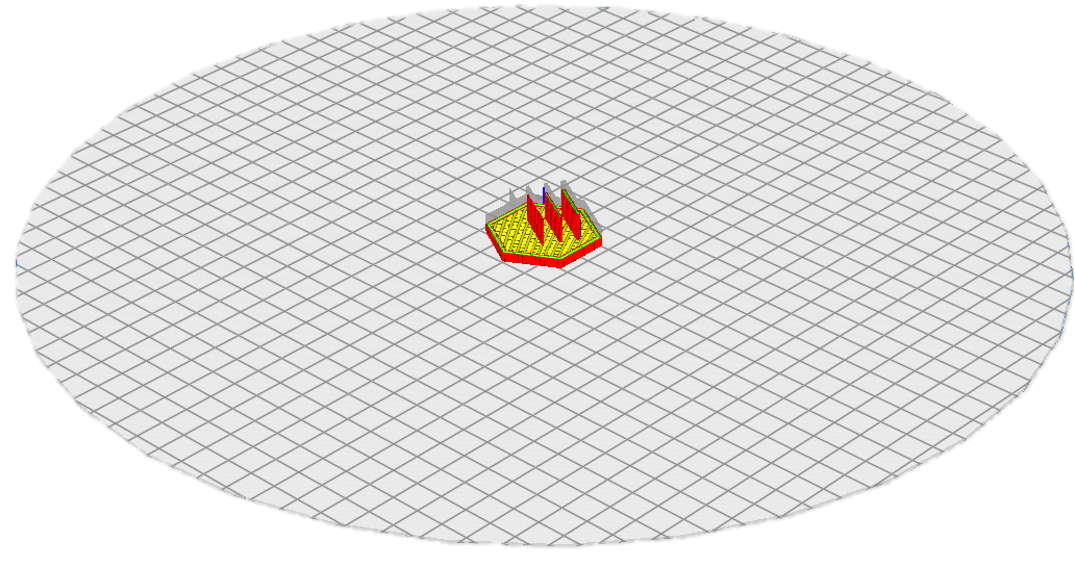

Part interpretation by Cura Slicing software.

The first wall has been ignored due to was ignored because it was too thin to be 3D printed with the selected nozzle.

To be 3D printable, two simple solutions:

- Reduce the nozzle size. It will increase the 3D printing time.

- Increase the wall thickness when possible.

Download the STL :

- Testing part - Thin walls

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.