Holes

Recommendations.

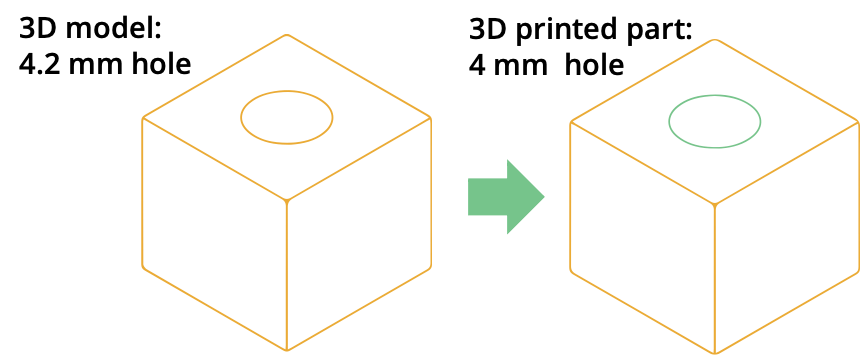

In 3D printing, the fabrication of vertical holes are often undersized. It is important to consider the manufacturing process to produce parts with right definition.

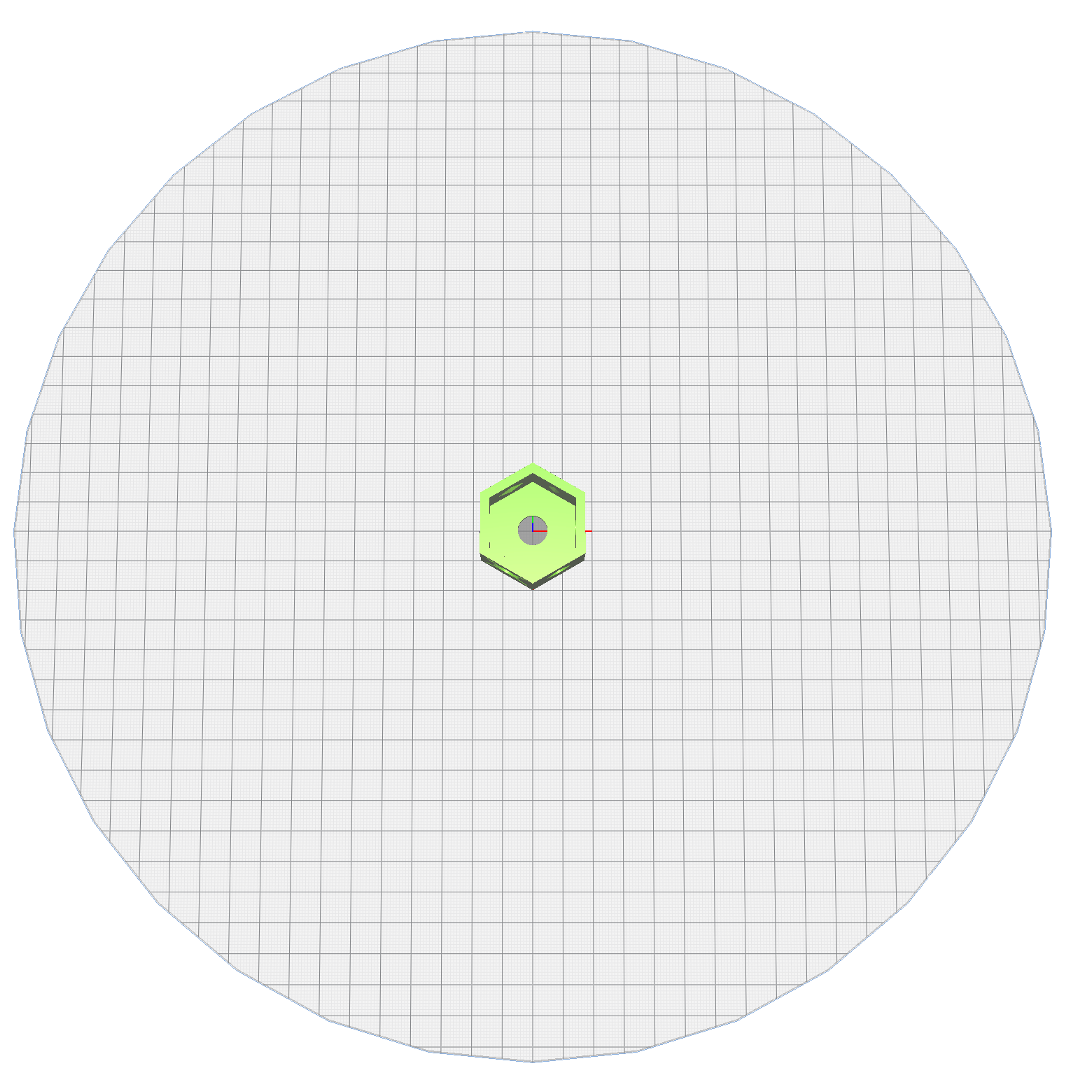

Focus on horizontal holes

In 3D printing, the fabrication of vertical holes are often undersized.

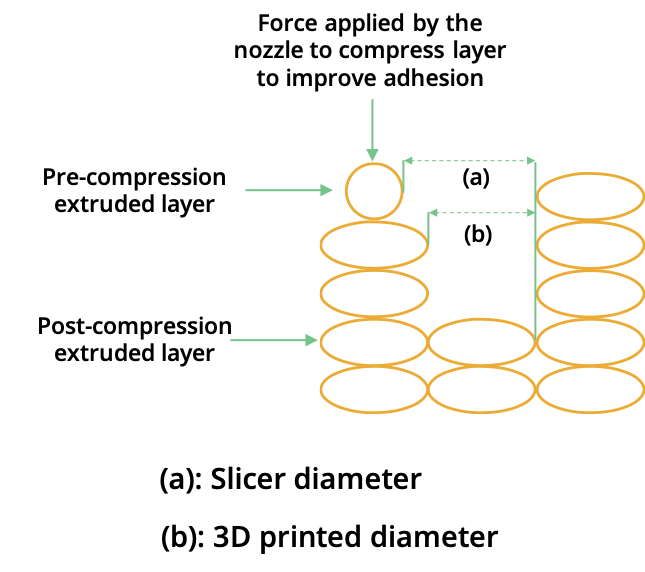

This is related to the manufacturing process, as the extruded material is compressed against the previous layer, expanding in the XY plane and making the holes smaller than expected.

Vertical hole size variations are affected by material type and 3D printing settings.

The best solution is to run tests to find the amount of under sizing and compensate for it in the design.

For example, to produce a 4 mm hole, it could be possible to add 0.2 mm to compensate it.

The standard nozzle diameter is Ø 0.4 mm and the wall thickness should be at least twice the nozzle diameter.

With a Ø 0.8 mm nozzle, the wall thickness should then be at least 1.6 mm.

In some condition Cura slicing software may ignored thinner walls and they may not be 3D printed although the surface quality and part strength will be reduced.

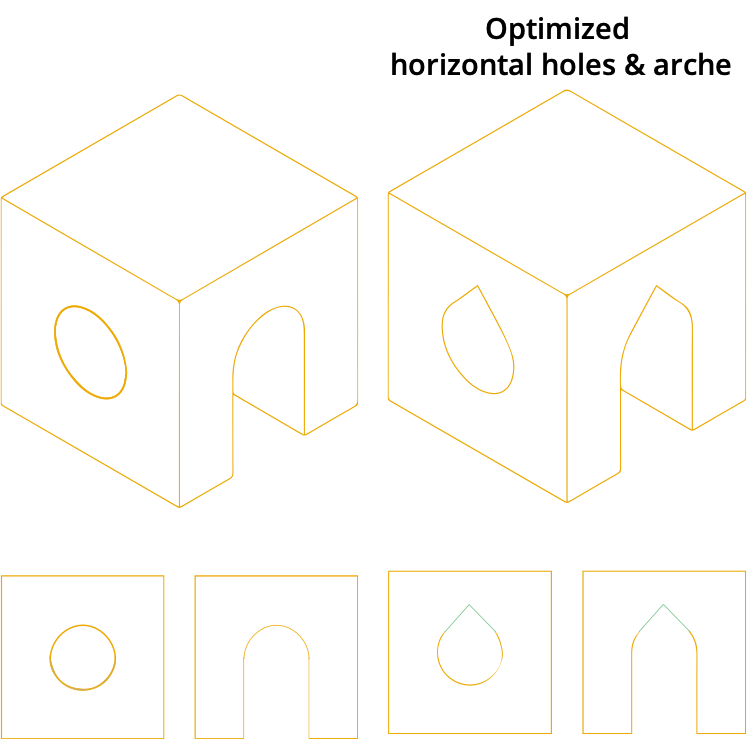

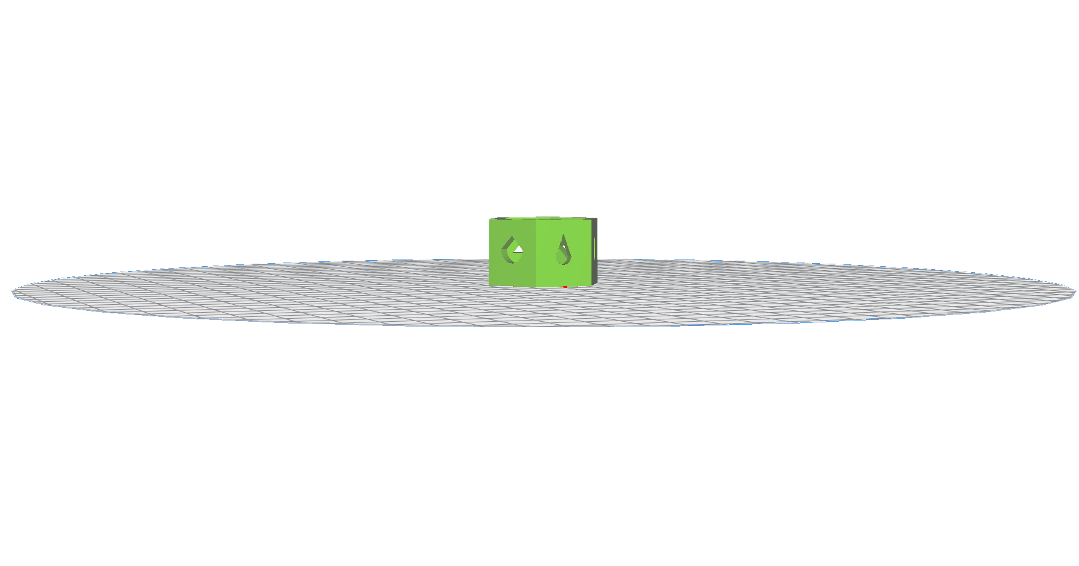

Focus on vertical holes & arches

Even though horizontal holes are also undersized, the cause for it is different. When designing a part that has horizontal holes or arches, the top part of the circle becomes an overhang.

If the holes and arches have a visual purpose, then using support structure material is the best option.

However, if the holes are functional and you're going to insert fasteners, it is possible to modify the design to transform it into a teardrop-shaped hole. This will change the overhang and give more options to control undersizing.

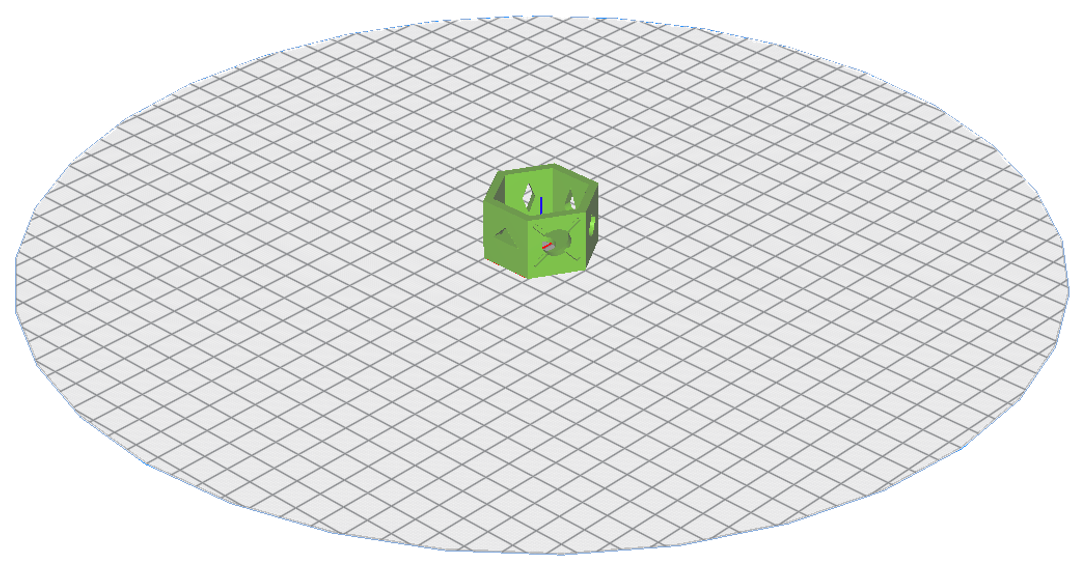

Testing part presentation with different holes.

Download the STL :

- Testing part - Vertical & Horizontal holes

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.