Edges, Fillets & Ribs

Recommendations.

To ensure a good 3D printability and to optimize the 3D printed part quality certain points must be taken into consideration.

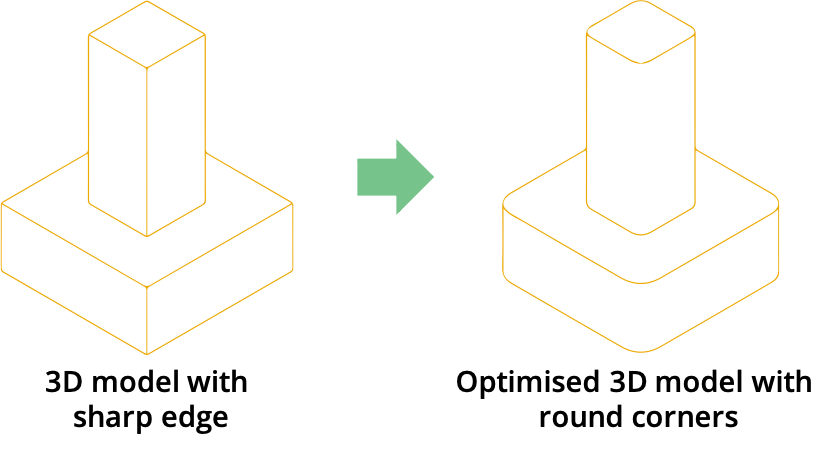

Focus on Edges

Few everyday pieces have sharp edges. One of the main reasons is that they are not very pleasant to handle. This is good news because in 3D printing, sharp edges are not recommended.

The reason behind is not ergonomics, but inertia. During a 3D printing cycle, the build plate moves needs to change its direction many times every minute.

If it needs to suddenly turn 90°, it will generate a lot of inertia, which will create artefacts on the surface of the model.

However, rounding the corners will reduce inertia and the surface of the 3D printed model will look cleaner.

A small 2 mm fillet can make a big difference.

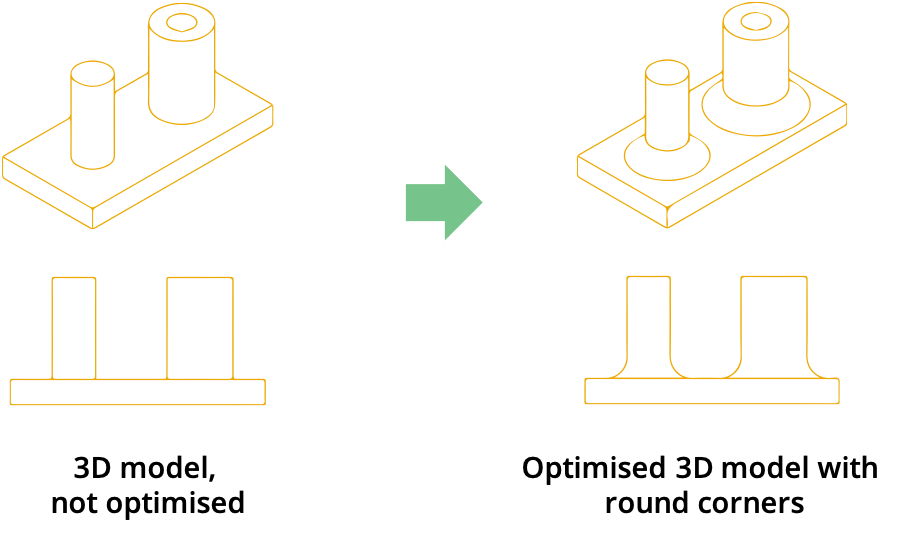

Focus on Fillets

To strengthen 3D printed parts, fillets are the easiest solution. This is especially useful for those fragile elements that connect to the main body.

Adding a simple fillet can strengthen the part and reduce stress concentrations.

Rounded edges are essential when designing enclosures as a certain strength must be achieved while having limited space and material.

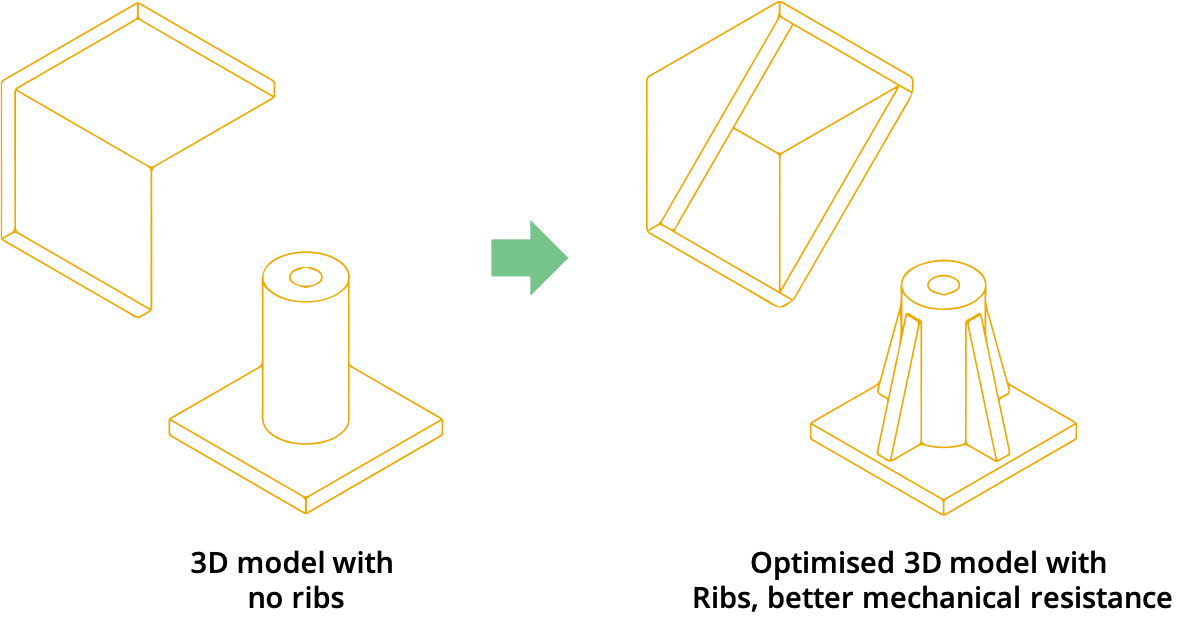

Focus on Ribs

Ribs are used to strengthen thin walls and to hold overhangs.

They can be combined with fillets if additional strength is needed and they're compatible with other manufacturing technologies such as injection moulding.

Testing part presentation with 6 different rounded edges.

Download the STL :

- Testing part - Edges

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.