Part Orientation

Recommendations.

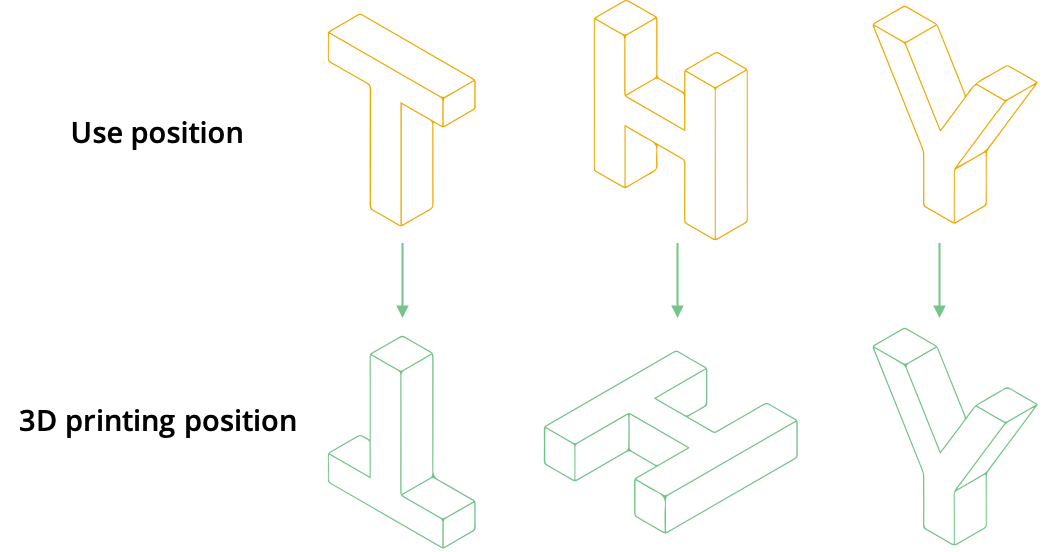

In most cases, the position in which the part is 3D print won't match the use position.

For example, with the letters THY we can see that only the letter Y can be easily 3D printed in its original position.

The goal when orienting a part is to reduce overhangs, bridges and any other elements that may reduce 3D print quality or success rate.

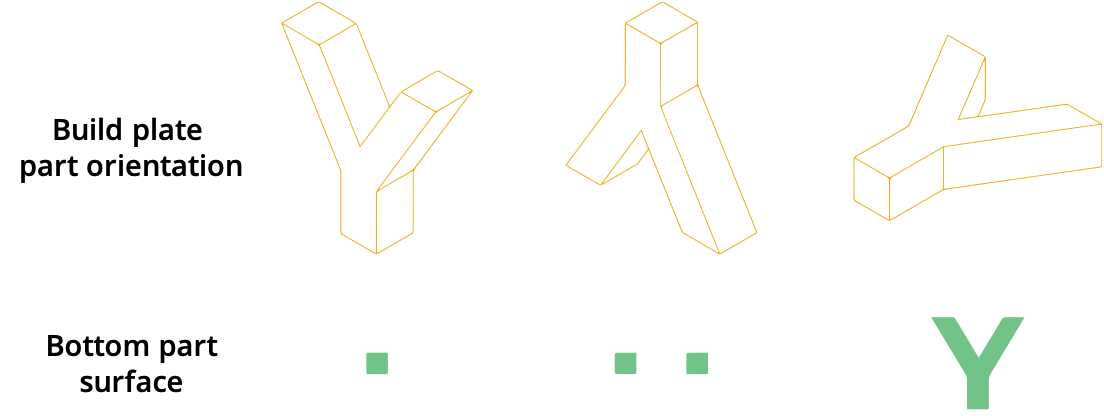

Bottom Part Surface

The first layer of the part is 3D printed over a flat surface, and it needs to stick to it during the all the production cycle.

Pam 3D printers are equipped with a heated build plate and specific print surfaces that increase part adhesion. However, it is also possible to design parts with enhanced 3D printability.

If a part can be 3D printed in multiple ways, it is advice to find the part orientation that covers the largest surface.

For example, if the letter Y is 3D printed in its original position, the first layer will consist of a small square.

Turning the Y upside down, the print surface will double.

However, if the model is rotated 90º and it lies flat, the print surface will enormously increase, reducing risks and increasing the print quality.

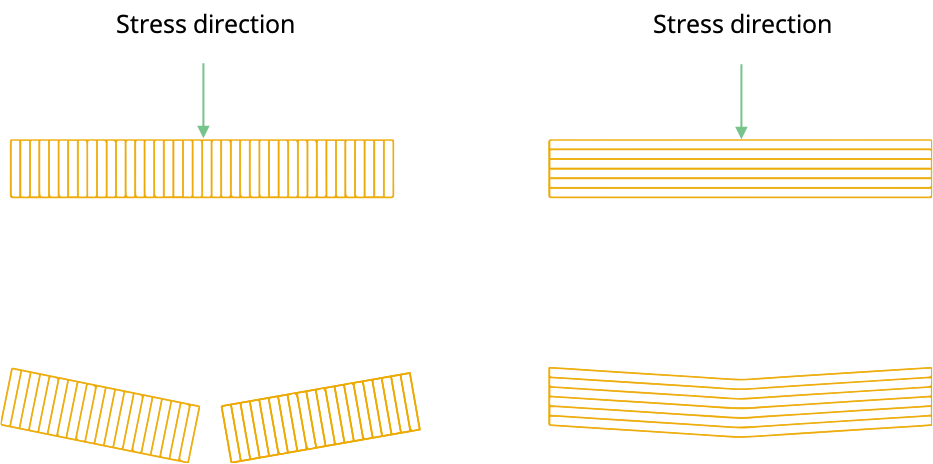

Use Orientation

Due to the manufacturing process, 3D printed parts are usually weaker in the direction perpendicular to the layers. This is related to how well the layers stick to each other, and print settings and materials should be taken into account.

To 3D print a functional part, it is important to consider the part orientation when preparing the files. The larger the surface of a layer is, the stronger.

For example, to produce a long part that needs to resist weight, it will be necessary to 3D print it in a way so that the layer lines are perpendicular to the weight direction.

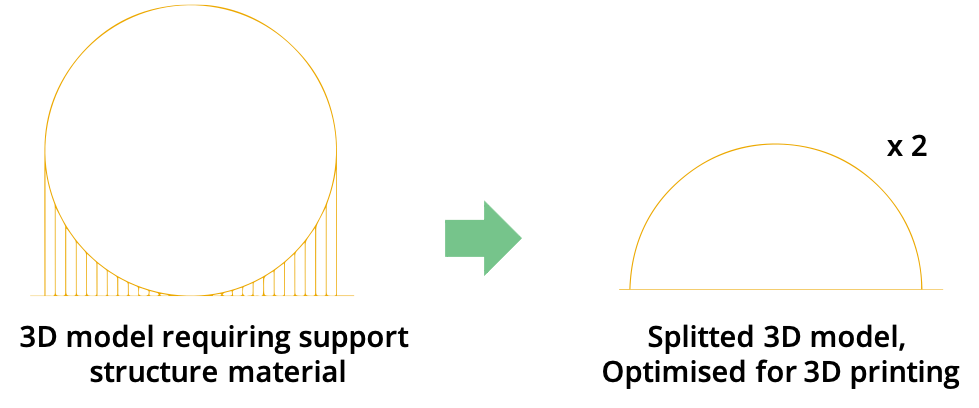

Split the model

With complex 3D model and if there is no way to 3D print it in an efficient way, it could be interesting to split it up.

Also, it will give the chance to optimize part orientation and increase the overall strength.

Splitting a 3D model is especially useful when working with organic or round shapes where there aren't flat bottom surfaces.

For example, 3D printing a sphere as one part would require support structure material and the bottom half risk to have a lower surface quality.

However, if by splitting the model into two halves, they can be 3D printed at high quality without support structure material.

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.