Minimum Feature Size

Recommendations.

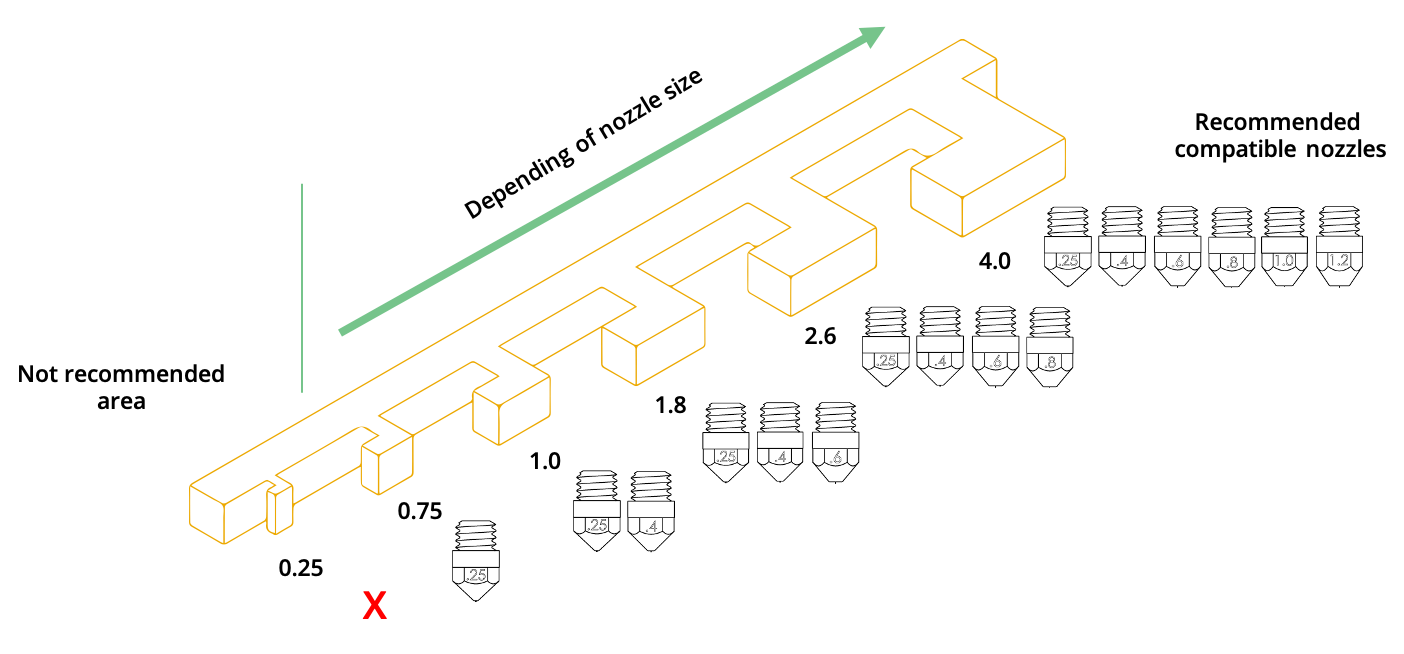

The smallest 3D printable feature of a 3D model is determined by the nozzle diameter and the motors the 3D printer uses.

Due to the manufacturing process, the extruded material needs to be shaped into a shape big enough so that the material can solidify keeping the original shape.

The minimum feature size for Pam 3D printing is 2-3 times the nozzle diameter, although the 3D model's shape and chosen material may demand slightly larger feature sizes.

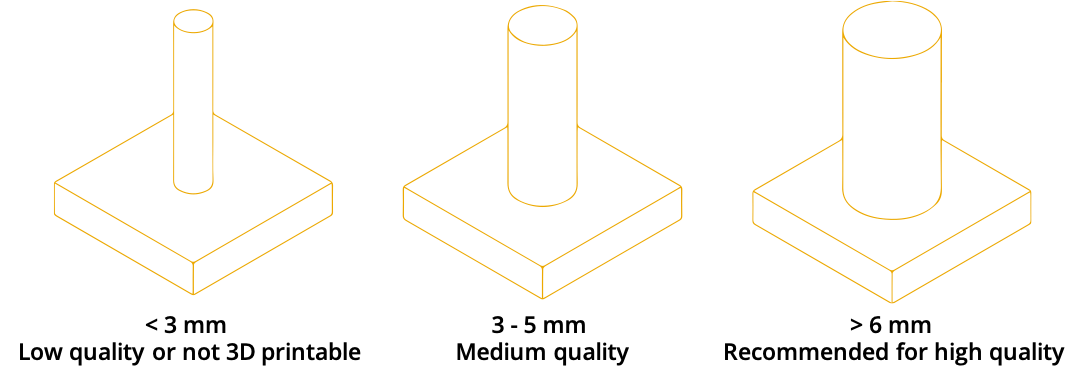

Within small features, vertical pins can be the trickiest ones.

Due to the small print surface and the fact that they're usually on the top part of the 3D model, they require a minimum size to print with decent quality.

Vertical pins with a diameter under 3 mm will probably deform when printed as the material is extruded faster than it can cool down and solidify.

Pins with diameters between 3 mm and 5 mm are big enough to print, but quality depends on the material and 3D printing settings.

If possible, 6 mm or larger pin size is recommended to get the best quality.

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.