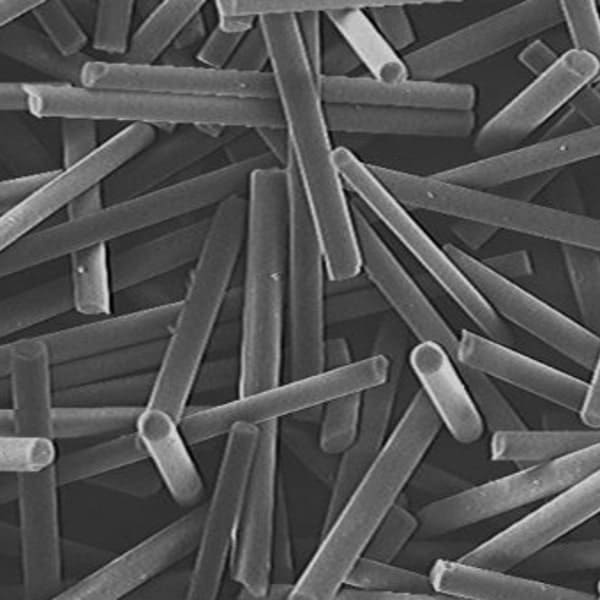

Glass fillers

Glass can be used as a filler in the form of fiber, it is then a so-called reinforcing filler, of hollow glass beads or of microspheres, making it possible to improve the performance of the polymer matrix or to reduce the mass of the parts produced.

Fiberglass: they are not strictly speaking charges but reinforcing agents.

Glass powder: its incorporation gives the resins better resistance to abrasion and compression, and allows for a lower and more homogeneous shrinkage of the molded parts.

Hollow glass beads: are obtained by heating glass beads containing a blowing agent. They improve the water and ageing resistance of thermoplastics.

Their density is between 0.45 and 0.38.

Glass microspheres: the use of glass microspheres reduces the mass of the parts obtained by 25 to 35%.

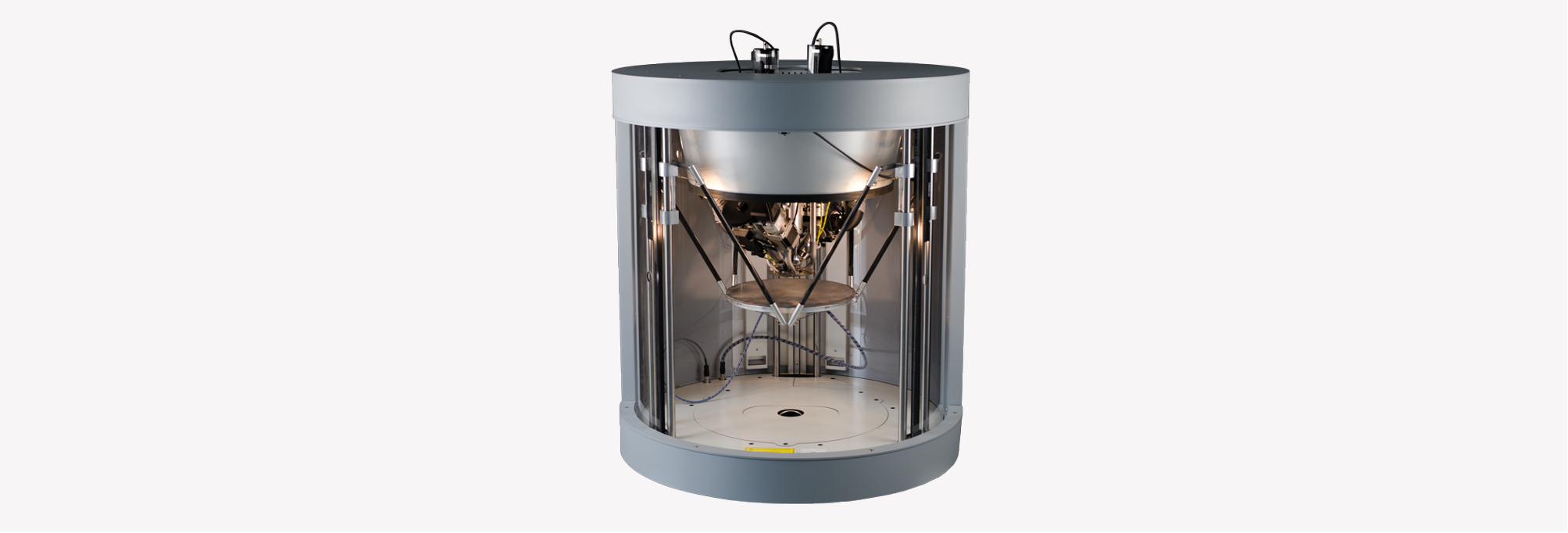

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

Newsletter

sign up for updates

We’ll never share your email address with anyone.

And you can opt out at any time. We promise.

© 2025 Pollen AM inc. All rights Reserved.

Français

Français