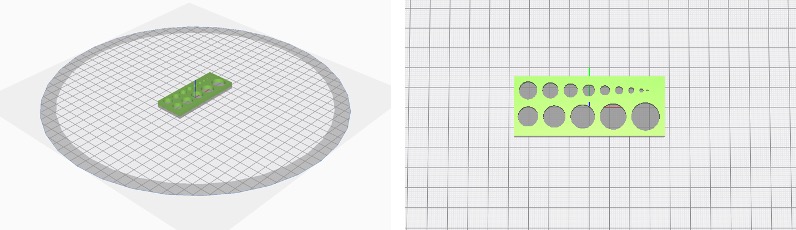

Integration of holes in the 3D printed part

with Pam 3D printers

Holes are an important part of the mechanical parts and must be adjusted to the material to achieve the correct tolerances.

Holes whose axis is in the direction of printing develop very well in the parts. However, it must be considered that the crushing of the material coming out of the nozzle has an impact on the hole diameter.

It is therefore advisable to print a smaller diameter than the specified one and to provide for redrilling.

Holes with horizontal axis will suffer from the overhang rule and become slightly or strongly deformed. Large holes usually require a supporting structure while small holes can be printed without any problem.

The use of a "teardrop" hole is recommended for holes larger than 10 mm. Unless adjusted in the printing parameters or in the design, holes tend to become slightly oval.

The stop-and-resume function during printing allows for the encapsulation of inserts into the part. This can be particularly useful when using inserts to obtain quality holes in the part.

Summary of hole management

| Element | Constraint | Proposed solutions |

Stage of the 3D printing chain | Good practices |

|---|---|---|---|---|

| Vertical axis holes | Crushing of the material that reduces the diameter of the hole | Plan a smaller diameter and use the hole after printing | Modeling / 3D printing | Optimize the realization with simple and fast post-processing steps |

| Encapsulate an insert | Modeling / Slicing / 3D printing | Take advantage of the stop / resume function to integrate functions using external elements | ||

| Horizontal axis holes | Overhanging surface | Use a soluble carrier | Slicing | 3D print with an open system to select or formulate a compatible material |

| Predict the shape of a teardrop hole | Modeling | Model shapes that allow printing without support | ||

| Encapsulate an insert | Modeling / Slicing / 3D printing | Take advantage of the stop/resume function to integrate functions using external elements |

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.