Integration of details

in 3D printing

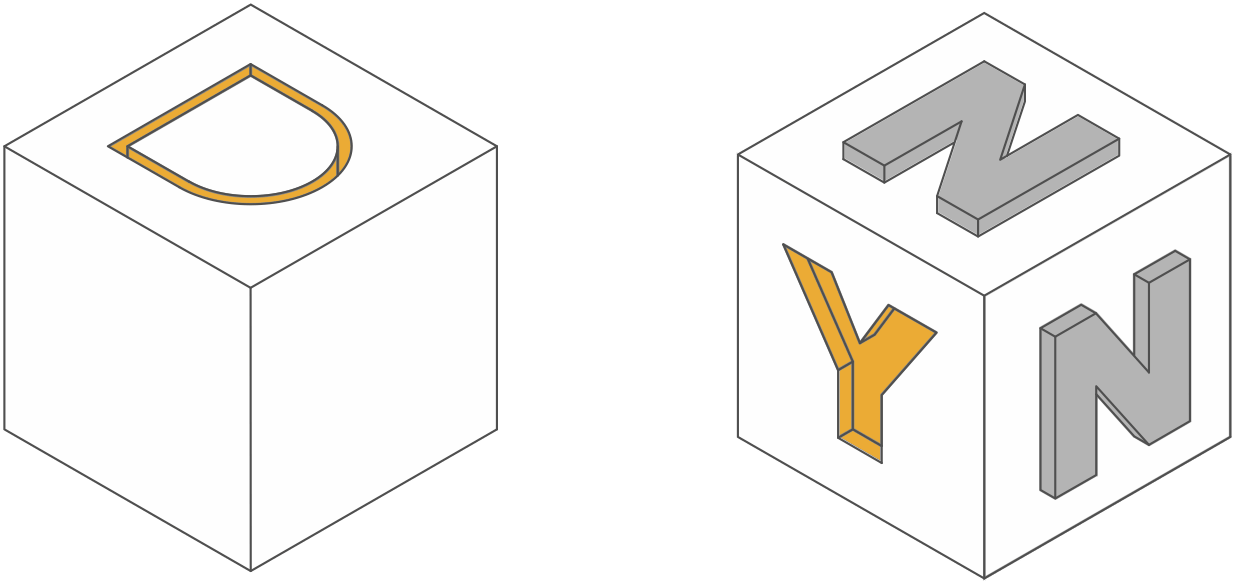

The printing of detail elements, such as an inscription, also have design rules related to the print profile to ensure satisfactory visibility.

Embossed printing must take into account the nozzle size used in printing. Relief prints must:

- have a minimum thickness of the nozzle size;

- have a minimum relief height of the nozzle size.

However, relief printing is not optimal and embossing is preferred whenever possible. Embossing is not dependent on the nozzle size on the x, y plane. The only rule is to ensure a minimum embossing depth of the nozzle size.

In cases where fine embossing is required and in order not to impact the printing time too strongly with a small nozzle size, Pam systems allow the development of multi-resolution print profiles.

Depending on the configuration of the system (2 to 4 extruders), it is possible to print the main part of a part with one nozzle and at the end of the printing process to provide a finish with a finer nozzle.

This solution, offered by the control of the printing parameters by the operator, guarantees an interesting compromise between fine details and general printing time.

Synthesis of the rules for the first deposited layer

| Constraint and element | Proposed solutions |

Stage of the 3D printing chain | Good practices |

|---|---|---|---|

| Details in relief | Details of a minimum geometry equal to the size of the nozzle used | Modeling / Slicing / 3D printing | Take advantage of multiple print heads to develop multi-resolution profiles |

| Minimum height of relief equal to the size of the nozzle used | Modeling / Slicing / 3D printing | Take advantage of multiple print heads to develop multi-resolution profiles | |

| Embossing details | Minimum depth of relief equal to the size of the nozzle used | Modeling | Favour embossing if possible less restrictive and time-consuming |

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.