Natural organic fillers

There are a number of natural organic fillers, the main ones being wood flour, vegetable fibers and starch.

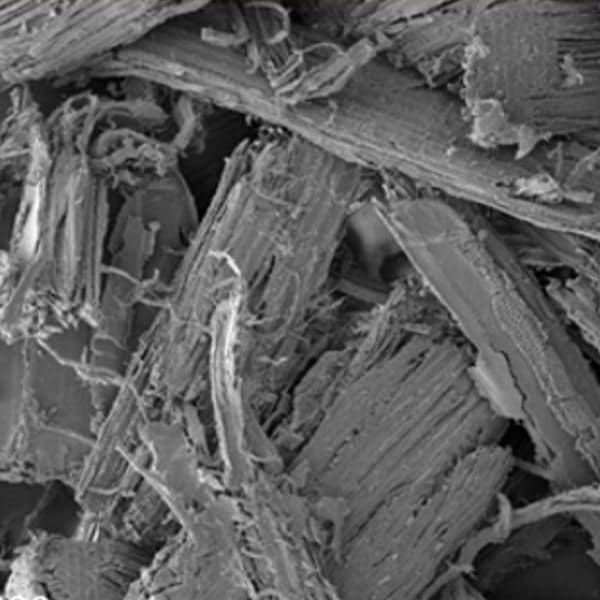

Wood flours: Obtained by grinding soft wood. Wood flours are crushed and dried, passed through various sieves to separate the particles according to their dimensions (between 50 and 200 μm in length for a few tens of micrometers in diameter).

They are used to reduce shrinkage during molding. Wood floor provides good electrical properties and impact resistance.

Vegetable fibers: They are made of cellulose, entirely for cotton fiber, partly for wood fiber and sisal.

Their density is low and they are very sensitive to humidity.

Their mechanical characteristics are low (on the other hand, they have a good resistance to wear and tear and provide thermal and electrical insulation.

| Tensile strength (MPa) |

Elastic modulus (GPa) |

|

|---|---|---|

| Cotton fibres | 400 to 700 | > 15 |

| Wood fibers | 500 to 1 000 | 6 to 11 |

Starch: They are carbohydrates contained in plants in particular polysaccharides having the general formula (C6H12O5)n.

The polysaccharides are obtained from cereal seeds (wheat, barley, rice, corn).

These various starches are very different in size and configuration: the smallest are those of rice (3 to 7 μm); those of corn make from 15 to 20 μm, those of wheat from 20 to 30 μm.

The starches are used as fillers to obtain plastics with controlled biodegradability.

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

Newsletter

sign up for updates

We’ll never share your email address with anyone.

And you can opt out at any time. We promise.

© 2026 Pollen AM inc. All rights Reserved.