Bio-Based Polymers

Focus on PLA

Polylactic acid or polylactide (PLA) belongs to the family of aliphatic polyesters is one of the most widely used biodegradable materials manufactured from lactic acid that in turn is produced from renewable resources such as corn, sugarcane and rice.

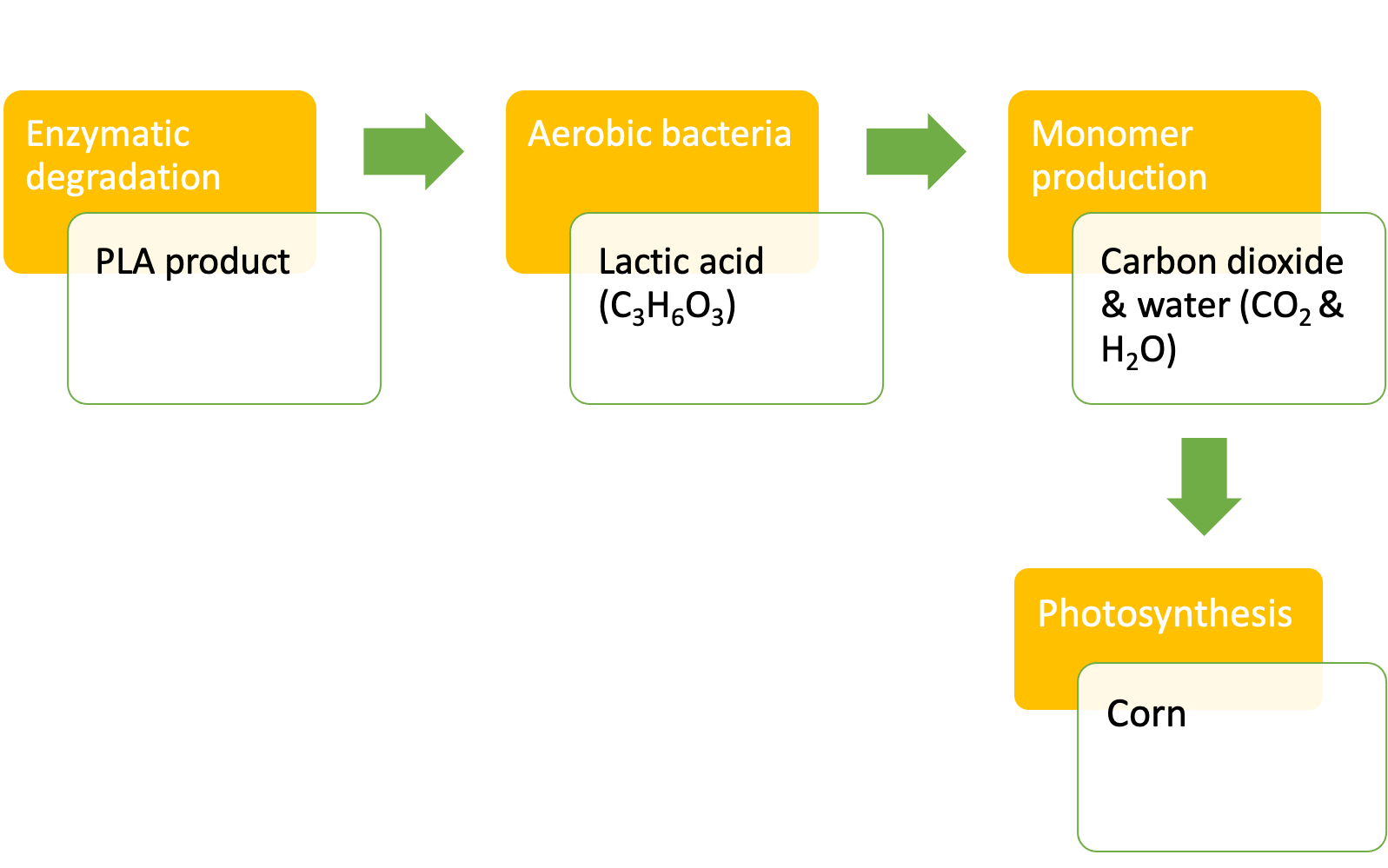

Besides being biodegradable and having produced from renewable resources, PLA provides numerous other benefits including: fixation of carbon dioxide, a greenhouse gas; significant amount of energy savings; improvement of farm economies and manipulation of physico-mechanical properties using polymer architecture such as orientation, blending, branching, cross-linking, or plasticization.

Although production processes for lactic acid and PLA are well known, very few processes have been commercialized and still the cost of PLA is not very competitive with synthetic plastics.

The core of PLA production technology is the fermentative production of lactic acid and its recovery.

To being biodegradable, PLA has many favorable properties such as good biocompatibility and bioresorbability, barrier properties, mechanical strength and the ability to reinforce fillers.

All of these properties make it a polymer of choice for biomedical (e.g. implants, sutures, drug encapsulation), food packaging (e.g. food wrap, container, drinking cups) and structural applications (e.g. civil structures, furniture, marine, automobiles). This chapter deals with production sources (i.e. raw materials), synthesis routes and its applications in biomedical, food packaging and structural fields.).

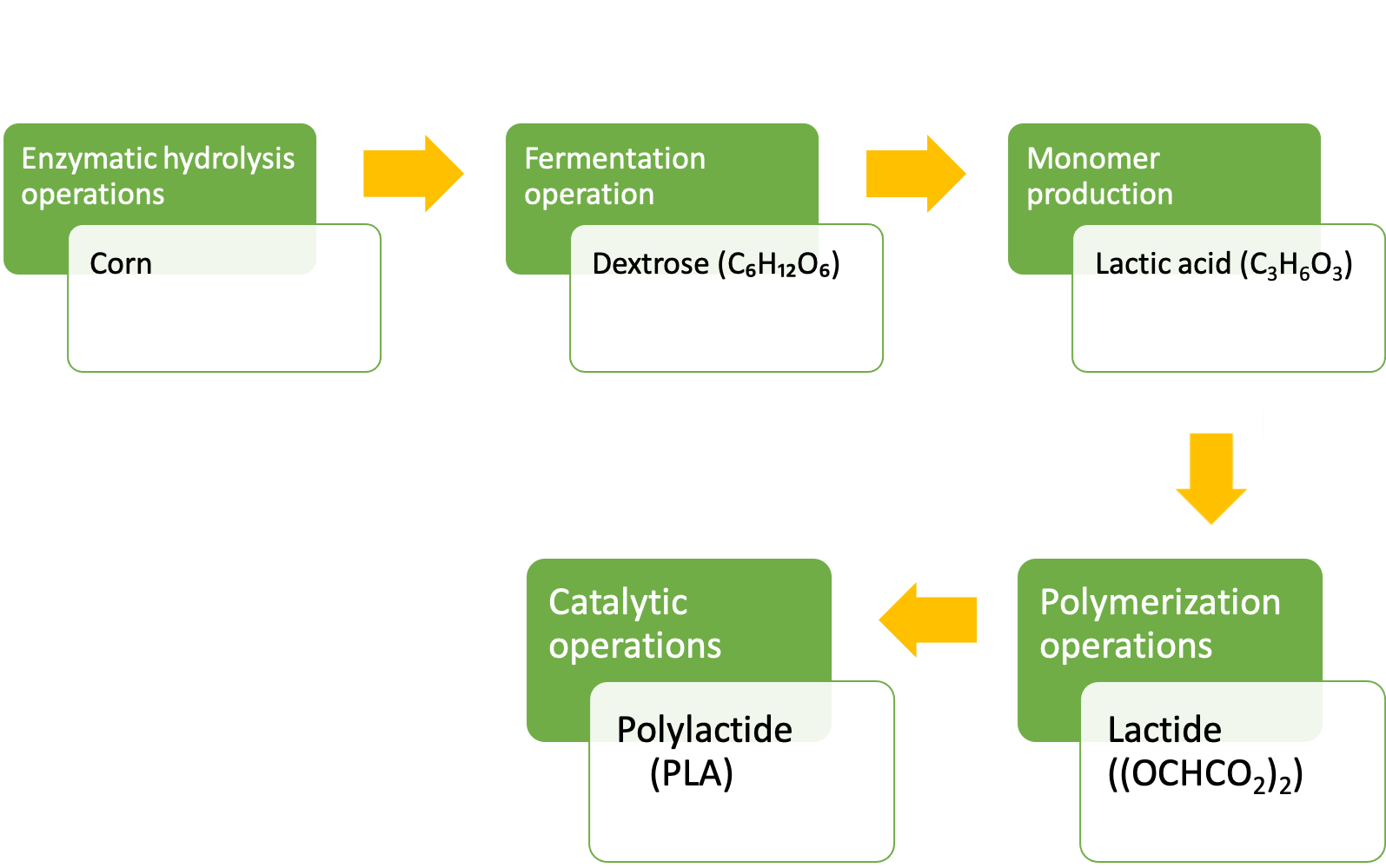

Currently, PLA is synthesized by a two-step process consisting of (i) lactic acid production by chemical synthesis from petroleum resources or mainly fermentation of environment friendly renewable resources or (ii) polymerization of lactic acid by direct condensation or solvent-based azeotropic dehydrative condensation and ring opening polymerization of lactide, a cyclic dimer resulting from the dehydration of lactic acid.

PLA in biomedical applications

PLA has high mechanical properties and excellent shaping and molding properties. It is biocompatible (which means it has good blood and tissue compatibility, and if slow degradation takes place, the degradation products are non-toxic) as well as bioresorbable (which means it can be broken down by the body and does not require mechanical removal) in the human body [18, 95]. Therefore, it is considered as one of the most important biodegradable polymers investigated for a wide range of biomedical and pharmaceutical applications such as controlled drug release, resorbable prostheses, biodegradable sutures, medical implants and scaffolds for tissue engineering.

The molecular weight of the polymer material directly influences the mechanical and sorptive properties of PLA and hence critical depending on the end use. High molecular weight polymer material is necessary for applications such as bone plates or temporary internal fixation of broken or damaged bones.

For being bioresorbable, PLA including other biodegradable polymers have been shown to be advantageous over the conventional polymers in case of parenteral controlled release systems.

The preparation of slabs for use in controlled release does not require high strength. Therefore, low molecular weight material can be used having the advantage of favorable degradation behavior in the human body. PLA has been used thus far as a drug carrier in the form of microcapsules, microspheres, pellets and tablets for the administration of antimycobacterial drugs, quinolones, anti malarial drugs, antiinflammatory drugs, antitumor agents, hormones and fluoride containing tablets for oral use.

PLA can be reinforced with non-resorbable materials such as carbon fibres to achieve carbon fibre/PLA composites of high mechanical properties before the implantation. The long term effects of resorbed materials in the living tissues are not completely known and are concerns yet to be resolved.

Materials from PLA and its copolymers have been designed to replace metal and other non-absorbable polymers as therapeutic aids in surgery, including pins, plates, screws, suture anchors, and intravascular stents. Other medical applications currently being practiced include dressings for burn victims, substrates for skin grafts and dental applications.

PLA as food packaging materials

PLA has a great opportunity to displace less environmentally benign materials in the area of packaging because it has favourable physical properties such as transparency, high elastic modulus and high melting temperature which often improves function as well as diminish environmental impact.

It is also medically proven as a safe material for food as the level of lactic acid that migrates to food from packaging materials is much lower than the amount of lactic acid used in common food ingredients. However, as a packaging material, initially PLA has found its application in high value films, rigid thermoforms, coated papers and food and beverage containers because of its higher cost. PLA may find its packaging applications for a broader array of products as modern and emerging production technologies lower its production costs.

By providing consumers with extra end-use benefits, such as meeting environmental regulations, PLA has become a growing alternative as a packaging material for demanding markets. PLA can be used as a food packaging polymer for short shelf life products such as fruit and vegetables. PLA also has common packaging applications such as containers, drinking cups, sundae and salad cups, overwrap and blister packages.

PLA can be processed in traditional polymer processing operations such as injection molding, blow molding, extrusion, and extrusion coating. As a result, lids, trays, and clamshells used in food handling can be thermoformed from extruded sheet PLA, even yielding products with higher flex-crack resistance in living hinges than those made of polystyrene. The thermoformed PLA containers are also being used in retail markets for fresh fruit and vegetables. Disposable cutlery can also be produced using injection molding of PLA.

Films are one of the largest application areas for PLA. The ability to be stress and thermo crystallized and also the ability to modify the crystallization kinetics and physical properties for a wide variety of applications by incorporation of D-or meso-co-monomer, branching, and change of molecular weight makes PLA an extremely versatile commodity polymer. Films are transparent when stress crystallized and have acceptance by customers for food contact. PLA films can be prepared by blown double bubble technology or by cast-tentering. The films obtained from cast-tentering have many properties desirable for consumer food packaging such as very low haze, excellent gloss, and good gas (O2, CO2, and H2O) transmission rates. For twist wrap packaging, PLA films have superior dead fold or twist retention.

Thin sheets of many PLA variants possess high gloss, excellent heat sealability and clarity, allowing extruded thin sheets of PLA to replace cellophane and polyethylene terephthalate (PET) in transparent packaging. Tough and puncture resistant bags for yard and/or food wastes form another set of applications in which not only the physical properties but also the biodegradable nature of PLA can be used to advantage. The biodegradable characteristic helps the bags to degrade within 4-6 weeks in a composting environment.

Structural applications / composites production of PLA

The use of traditional composites made of glass, aramid or carbon fibre with synthetic polymers of petrochemical origin have been used for aerospace, defense, marine, automotive, civil infrastructure and sporting goods for more than two decades for their high strength and stiffness, dimensional stability, and thermal properties.

However, finite nature of the synthetic polymers and fibres and due to new imperatives on environmental pollution, the focus of the researchers is shifted to bio-composites based on natural resources with the application areas remaining the same.

Bio-composites made of biopolymers (e.g. PLA, cellulose esters, polyhydoxyalkanoates and starch) and natural fibres (such as flax, hemp, kenaf, jute or cotton) are generally biodegradable and are important research and development achievements.

PLA is expensive in comparison to conventional thermoplastics and they are sometimes too weak for some applications especially the inherent brittleness of PLA has been the main obstacle to expanding its commercial use. To reduce the cost and also to improve the properties of the material PLA without interfering its "green polymer" image, many researchers have investigated natural fibre reinforced PLA bio-composites for structural applications.

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.