Bio-Based Polymers

Focus on Bio-PE

PE is the largest polymer used in the world. The starting monomer used for synthesis is ethylene, which is also the case for other polymers such as PVC and PS, and it is generally obtained from petroleum feedstock by distillation.

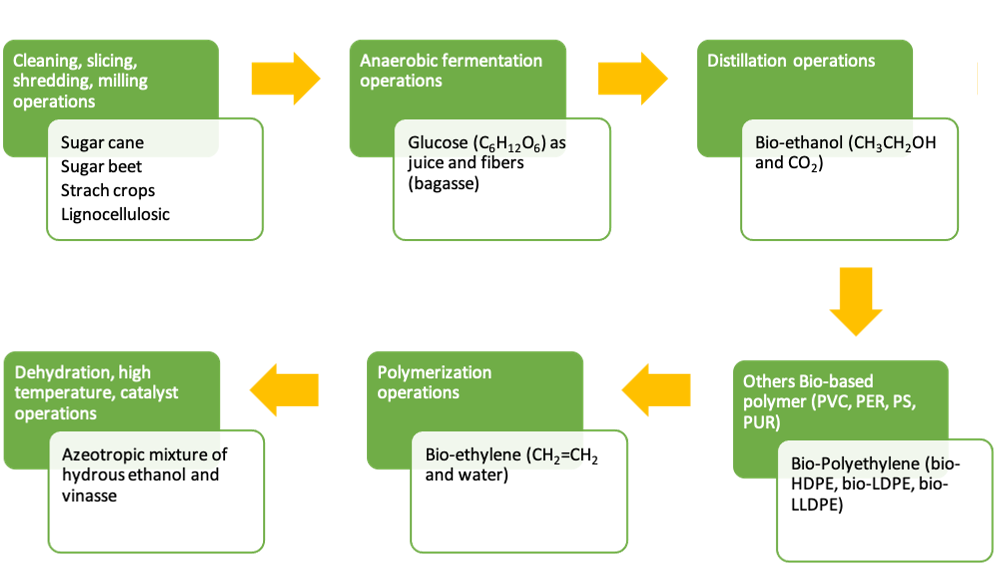

However, great interest is now being shown to obtain this polymer from biological resources, and, as of now, the followed approach has been to synthetize the ethylene monomer by dehydration of bio-ethanol, obtained from glucose.

Glucose could be obtained from different biological feedstocks, such as sugar cane, sugar beet, starch crops coming from maize, wheat or other grains and lignocellulosic materials.

When starting from sugar cane, processes like cleaning, slicing, shredding and milling are used to obtain the main sugar cane juice product and the sugar cane fiber by-product (bagasse).

The juice, containing 12–13% of sucrose, is anaerobically fermented in order to obtain ethanol.

The ethanol is distilled in order to remove water, giving an azeotropic solution of hydrous ethanol, at 95.5 vol.-%, and a by-product named vinasse.

The subsequent polymerization of the ethylene monomer obtained this way is the same that is followed when using ethylene derived from petroleum, and the corresponding bio-polymer is identical in its chemical, physical, mechanical properties to fossil-based PE, also with regards to the mechanical recycling processes.

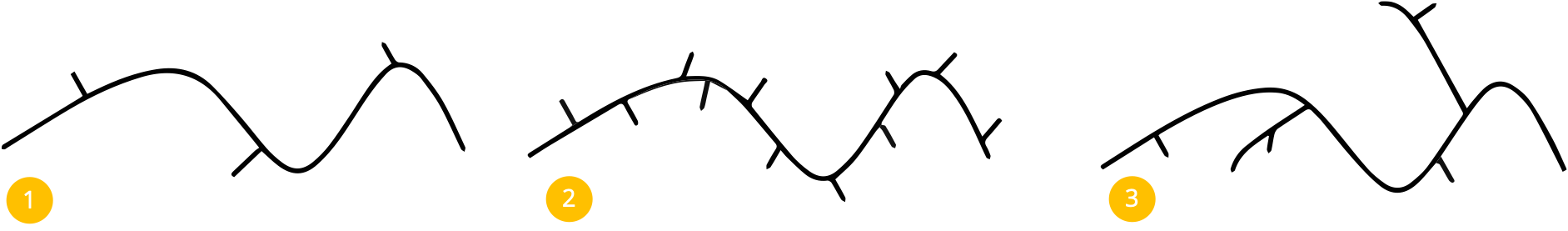

From polymerization, di↵erent types of bio-PE could be obtained: bio-HDPE with a low degree of short-chain branching (about seven branches per 1000 C atoms), bio-LLDPE with a high degree of short-chain branching and bio-LDPE with a high degree of short-chain branching + long-chain branching (about 60 branches per 1000 C atoms).

General chemical structure of HDPE, LLDPE and LDPE polymers :

(1) HDPE, (2) LLDPE, (3) LDPE.

LLDPE is obtained by copolymerization of ethylene and butene, hexane or octane. For its processing, the same plant and machinery can be used.

Bio-PE is not biodegradable.

The bagasse by-product is used as a primary fuel source in the sugar mill process because its combustion produces an amount of heat that can cover the energy needs. A surplus of heat and/or electricity can also be produced.

Vinasse by-product can instead be used as fertilizer.

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.