Bio-Based Polymers

Focus on Bio-PET

Polyesters represent a large group of polymers that have the potential to be produced from bio-based feedstocks.

The most relevant for a shift towards bio-based chemicals are PET, PBT, PBS, PBA and the copolymers PBAT, poly(butylene succinate-co-lactate) (PBSL), poly(butylene succinate adipate) (PBSA) and poly(butylene succinate terephthalate) (PBST), but also polyvinylacetate (PVAc), polyacrylates, poly(trimethylene naphthalate) (PTN), poly(trimethylene isophthalate) (PTI) and thermoplastic polyester elastomer.

Those polymers are produced from a bio-based diol, while diacid or diester could be either bio-based (like succinic or adipic acid) or petrochemical-based (like PTA and/or di-methyl terephthalate, DMT).

Among them, PET is the largest used polyester, with physical and mechanical properties that make it suitable to be used for fibers (65%) and packaging (35%) applications.

This last application regards bottles (76%), containers (11%) and films (13%). It plays an important role in the plastic market, but due to its poor sustainability due to a much slower degradability, it poses serious environmental issues, especially for waste treatment, when it is used for short time applications, as for example when it is employed as food packaging.

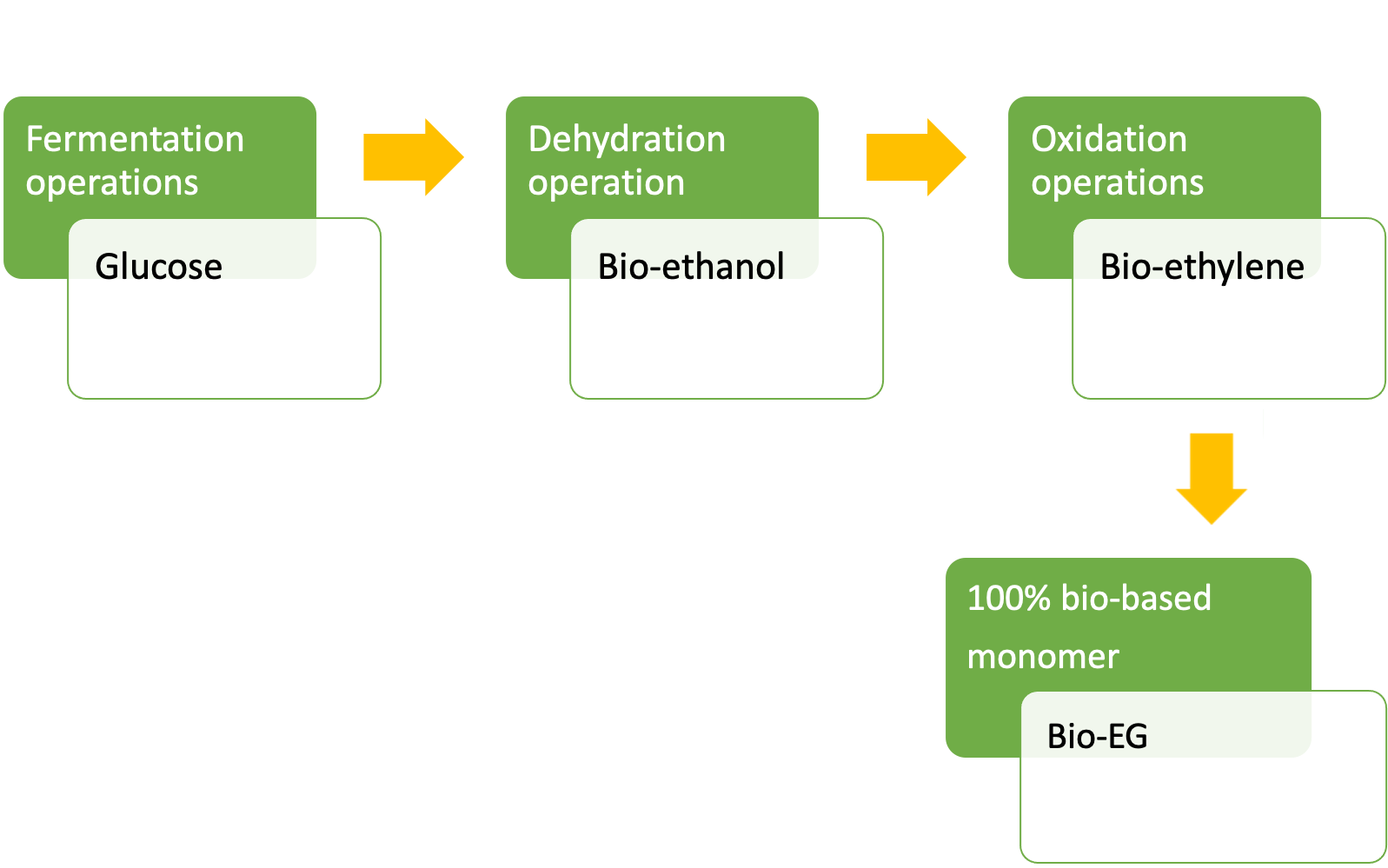

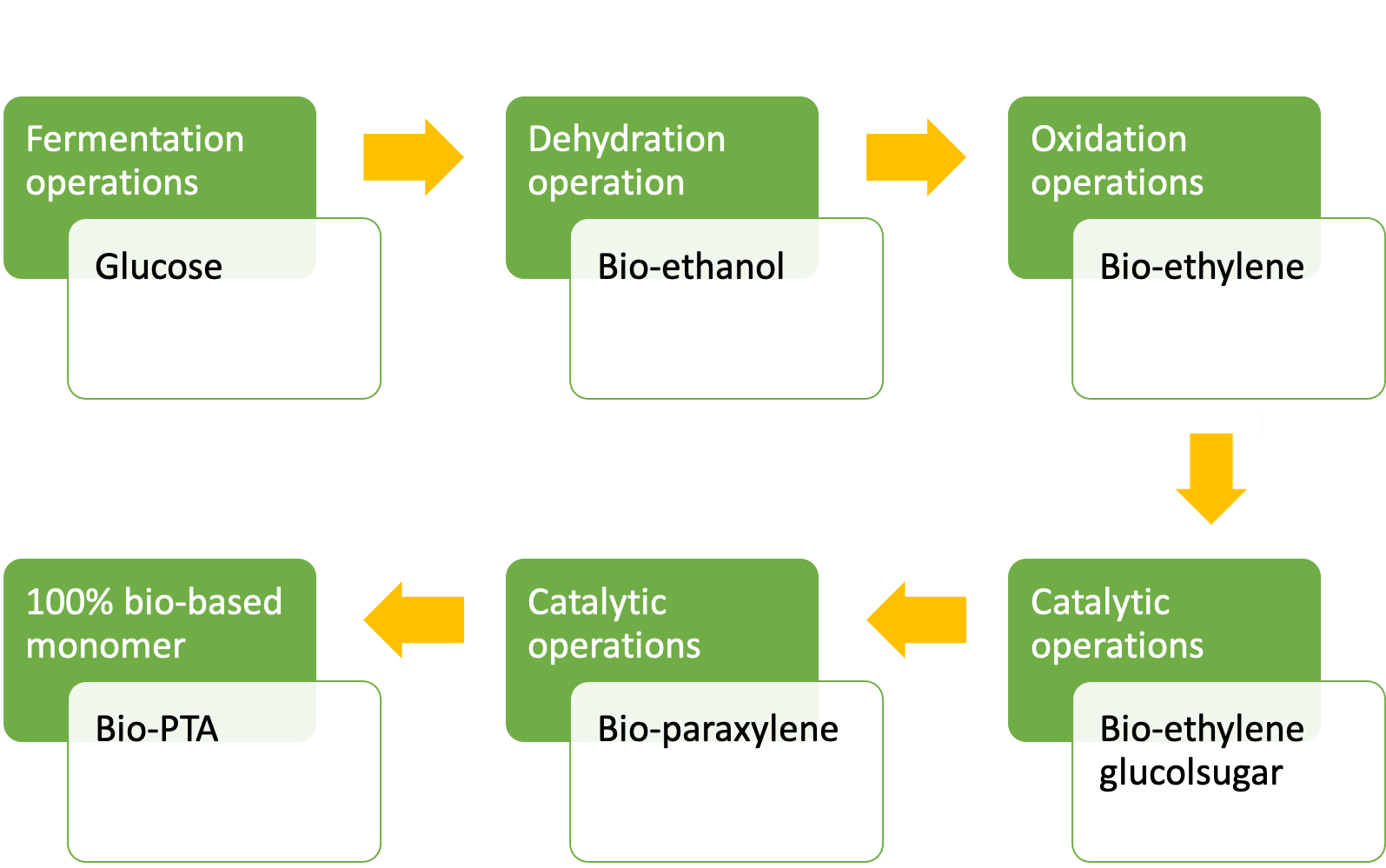

In order to realize a sustainable plastic, both starting chemicals such as ethylene glycol (EG) and PTA and/or DMT monomers have to be obtained from biological sources.

General scheme for Bio-EG and Bio-PTA monomers production.

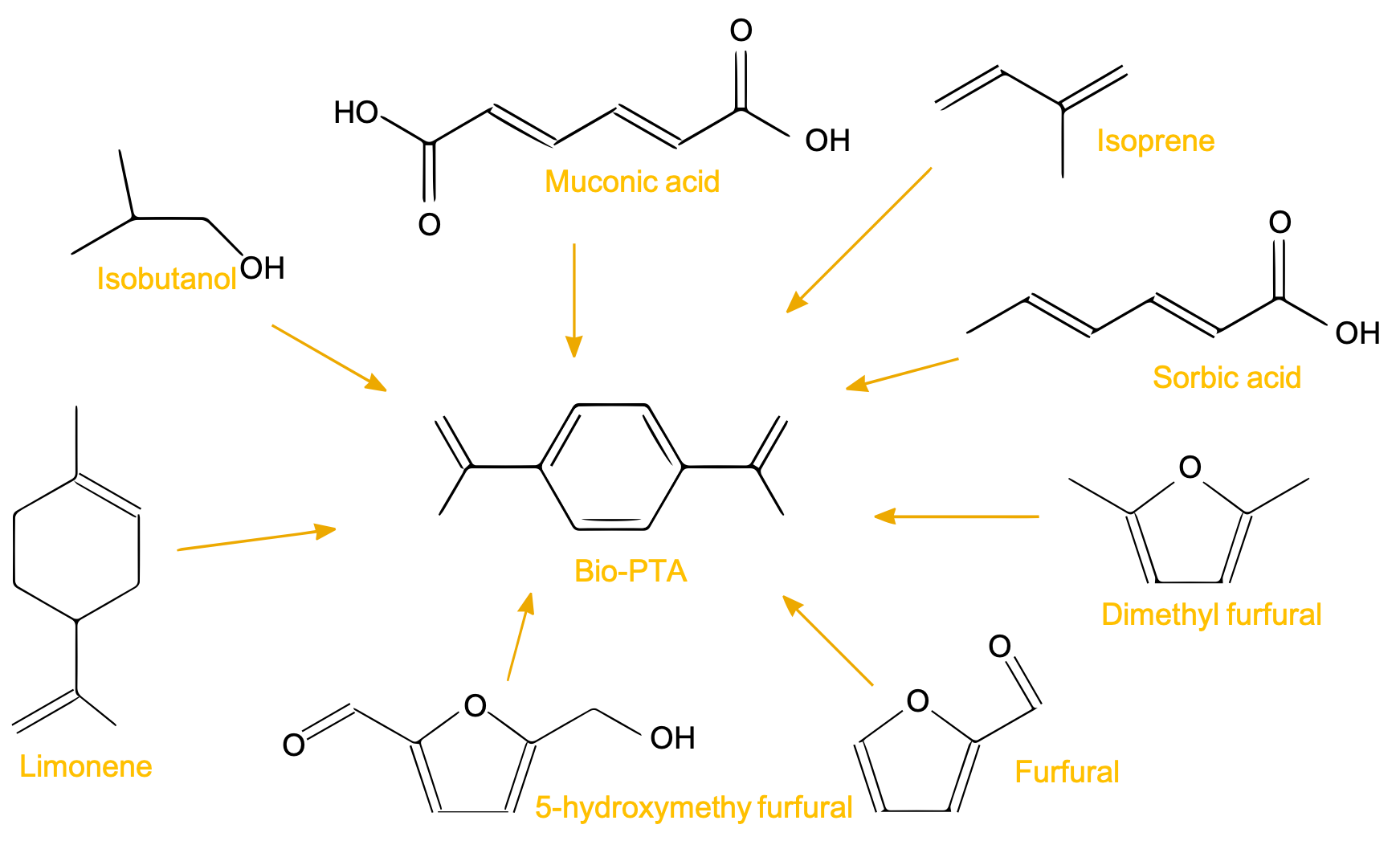

An interesting advantage of furfural is that it can be easily converted into other chemicals used for the synthesis of bio-based polymers, such as PBS and polyoxabicyclates.

Bio-based PET is identical to petrochemical PET and can be processed by injection molding, blow molding and extrusion, and direct 3D printing processes.

This Bio-based PET is not biodegradable, nev ertheless some microbial degradation of PET exist. Due to the action of microbial polyester hydrolase, considered a key alternative for recycling PET.

Actually, the glycolysis method is advantageous for depolymerizing opaque and colored PET that cannot be recycled due to the presence of pigments, but the high energy cost associated with the high temperature required and the long reaction times needed for depolymerization make this process not economic and environmentally sustainable.

The resulting EG and PTA monomers could be reused in the synthesis of PET, as well as for other polymers.

As an alternative to chemical PET depolymerization methods, a series of enzymes coming from different microorganisms could be used for a more sustainable strategy.

Bio-based polymers, either biodegradable or non-biodegradable, are certified as bio-based according to international standards such as EN 16640:2015, ISO 16620-4:2016, ASTM 6866-18 and EN 16785-1:2015.

In particular, EN 16640:2015, ISO 16620-4:2016 and ASTM 6866-18 measure the bio-based carbon content in a material through 14C measurements, while EN 16785-1:2015 measures the bio-based content of a material using radiocarbon and elemental analyses.

An alternative approach is to replace terephthalic acid by different compounds derived from biomass, such as 2,5-furandicarboxylic acid (FDCA) for the production of polyethylene furanoate (PEF).

Schematic representation of the methods used to achieve Bio-PTA.

LLDPE is obtained by copolymerization of ethylene and butene, hexane or octane. For its processing, the same plant and machinery can be used.

Bio-PE is not biodegradable.

The bagasse by-product is used as a primary fuel source in the sugar mill process because its combustion produces an amount of heat that can cover the energy needs. A surplus of heat and/or electricity can also be produced.

Vinasse by-product can instead be used as fertilizer.

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.