CA - Cellulosic acetate

Cellulosic acetate (CA) material is esters bio-based polymers. They are produced through reaction of cellulose with organic acids, anhydrides or acid chlorides. Cellulose acetate is one of the oldest bio-based polymers in the world. Due to its properties, thermoplastic CA is a promising biopolymer for replacing PS in certain foam applications.

CA is commonly used for producing writing instruments, glasses, tool and knife grips, profiles and pipes, electrical goods, etc.

Main 3D printing parameters

| Advised nozzles | Brass 0.25 | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 mm |

| Printing temperatures | 190 - 230°C |

| Buildplate substrate | PEI film | PC film | PA film | Micro-perforated buildplate |

| Builplate temperature | 50 - 80°C |

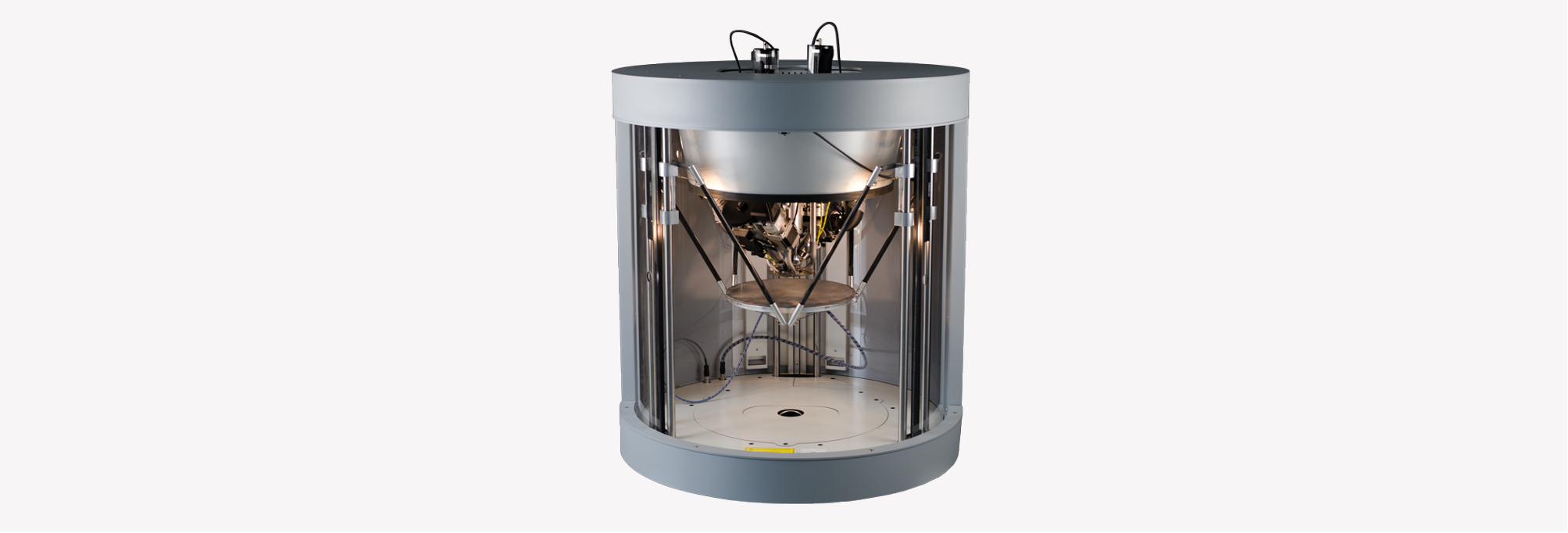

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

Français

Français