PA-12 - Polyamide-12

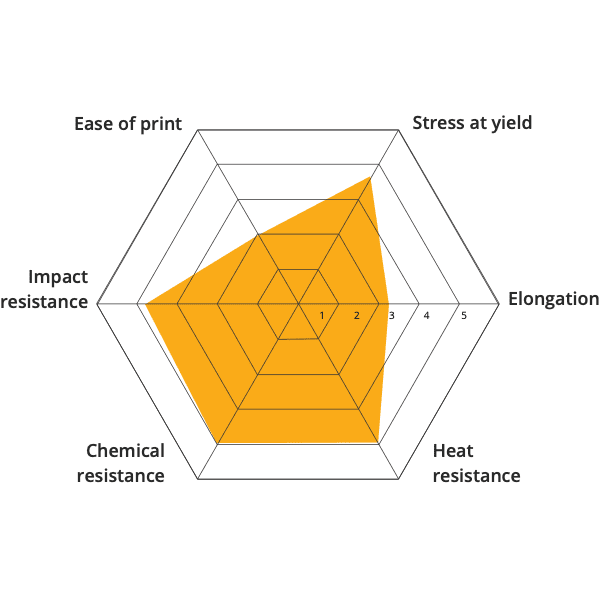

Polyamide-12 (PA-12) is a semi-crystalline white industrial thermoplastic very similar to nylon 11 whose properties are generally slightly superior. Of all the unmodified generic nylons, it has lower values in water absorption rate, heat resistance and stress resistance. Compared with nylon 6 and 6.6, they both have a much lower water absorption rate (resulting in better electrical properties and better dimensional stability) and a higher cost.

PA 12 is the ideal material for applications in the field of conveyor and drive technology such as wheels or pinions and precision industrial components requiring solidity at low temperatures.

Main 3D printing parameters

| Advised nozzles | Brass 0.25 | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 mm |

| Printing temperatures | 230 - 300°C |

| Buildplate substrate | PA film | Micro-perforated buildplate |

| Builplate temperature | 80 - 90°C |

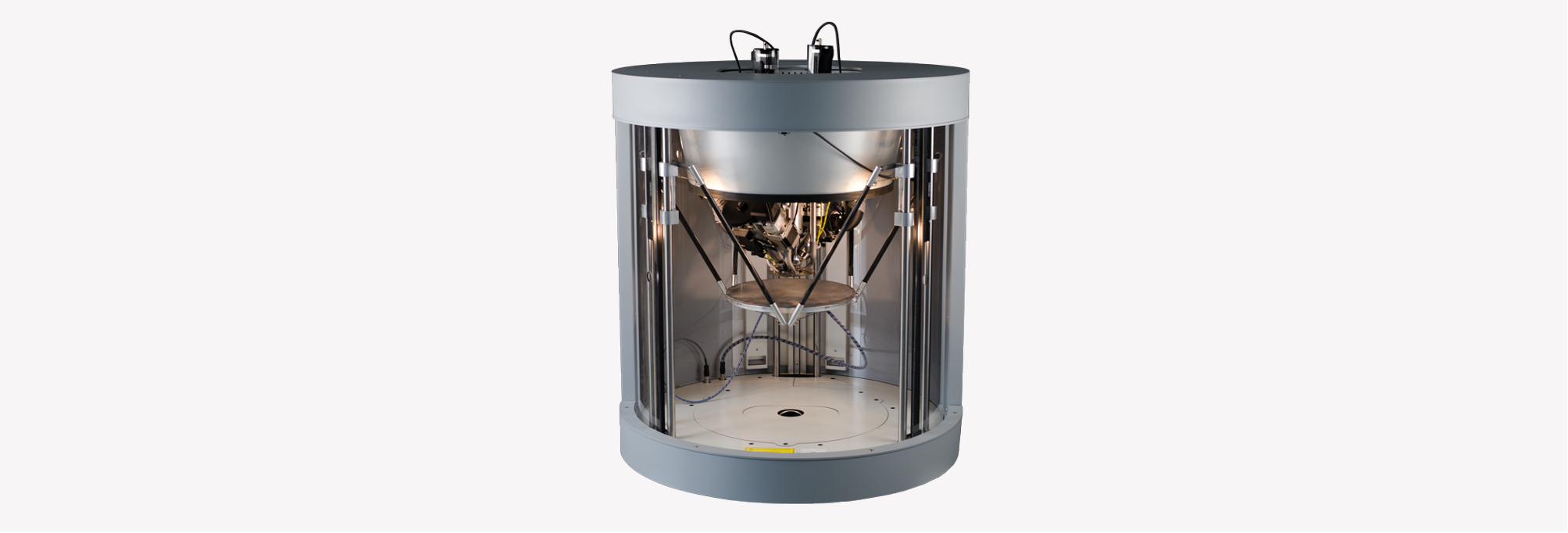

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

Français

Français