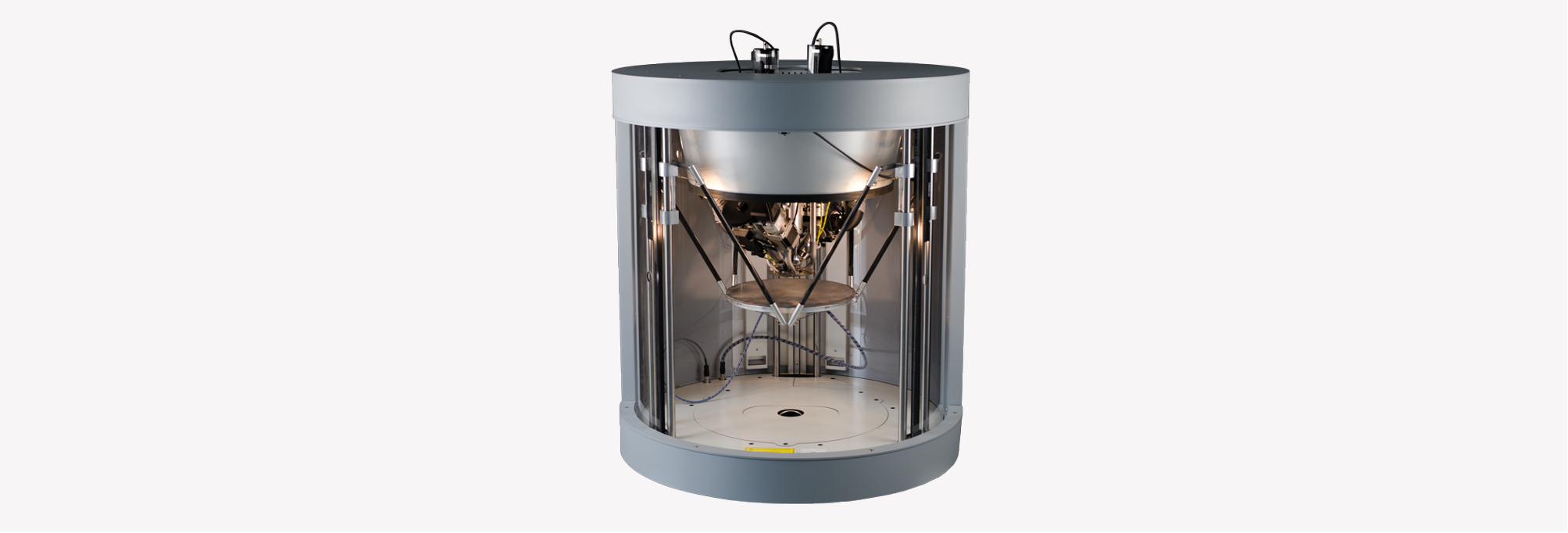

Open to materials 3D printer

Pam 3D printers enable its users to work with the materials they are familiar with. It begins with standard pellet shape materials (granules).

That is to say, the same materials as the one used in injection molding processes.

The first condition is that the material must be qualified, in other words, key processing parameters need to be determined.

This can be done directly by users thanks to the opening of Pam 3D printers, access to all printing parameters and a training course available at any time.

Also, our teams can perform the qualification of new materials.

Pam 3D printers are versatile and allow their users to find a solution and transform that meet standards such as skin contact, food contact fire retardant, anti-static, etc.

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

Français

Français