BVOH - Butenediol vinyl alcohol co-polymer

BVOH (Butenediol vinyl alcohol co-polymer) is a water-soluble support material. It is used to 3D print support structures when producing cantilever parts.

Depending on the materials and angles of inclination, it becomes necessary to use support structures to maintain stability and good performance of the 3D printed part. BVOH is sensitive to moisture and heat.

Main 3D printing parameters

| Advised nozzles | Brass 0.25 | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 mm |

| Printing temperatures | 190 - 230°C |

| Buildplate substrate | PEI film | Adhesive helper |

| Builplate temperature | 70 - 80°C |

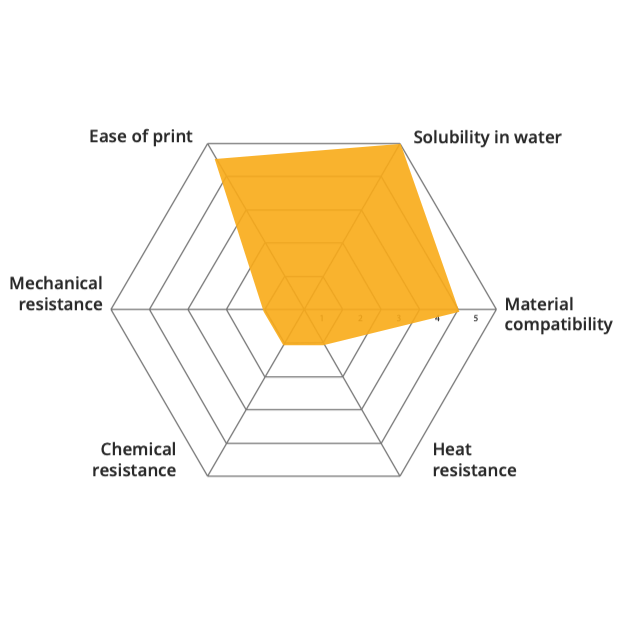

Typical properties

3D printing geometry with overhanging surfaces requires printing support structures that support the part during printing and then are removed from the part after printing.

When the geometry requires the use of support, then there are two solutions:

- the support is made from the same material as the 3D printed part: The support parameters are then determined to facilitate mechanical removal. Unfortunately, this solution remains time-consuming and degrades the surface at the level of the part / support interfaces.

- the support is made from a soluble material: this solution is by far the most comfortable. It makes it possible to generate supports which can be dissolved subsequently by immersing the part in a solvent.

To implement this solution, it is necessary to identify a material that is compatible in adhesion with the 3D printed structure material and soluble in a solvent which does not react with the part.

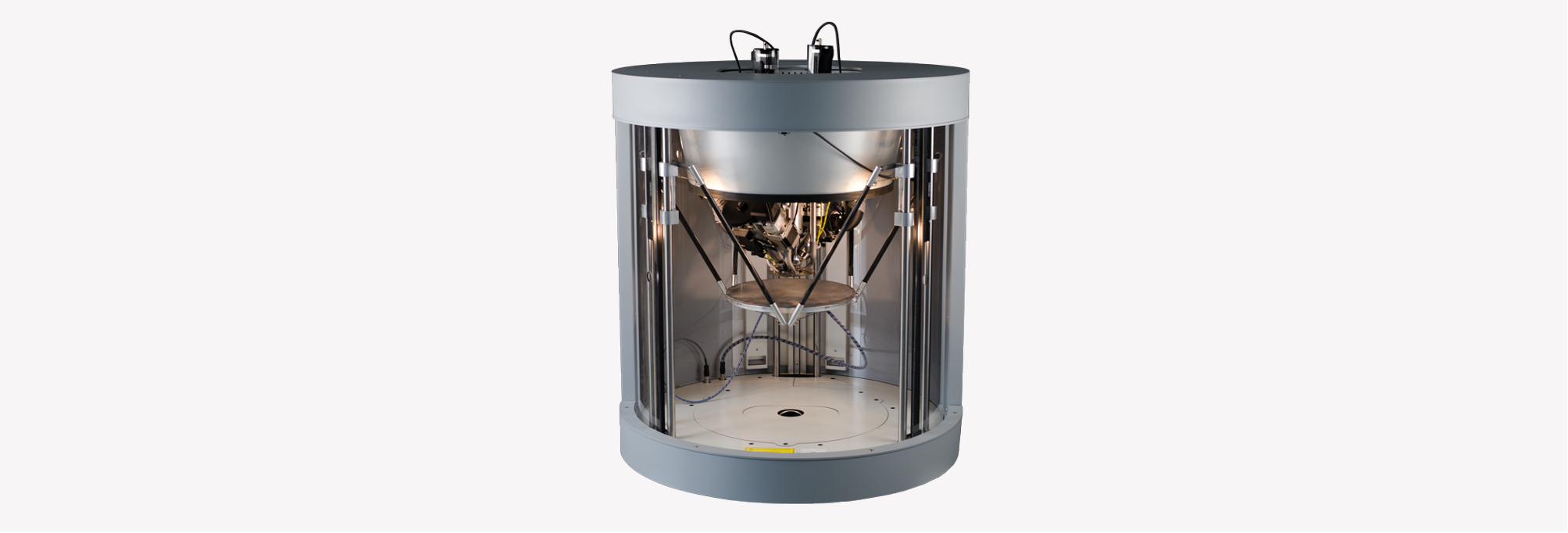

The openness of the Pam systems to the pellets shape material, the most common material format, is a great advantage in this context. It becomes easier to identify the materials (or mix of materials) of interest as support that can fit the material to be processed and then develop an adapted printing profile.

To extend the possibilities to generate soluble supports for a wide variety of materials, Pollen AM works continuously to integrate new materials that can meet the users’ needs.

BVOH has excellent compatibility as a support material with many polymers, including ABS, ASA, PLA, PC, PA, TPU and some TPEs. It is also non-toxic and has a very good solubility in water, better than PVOH.

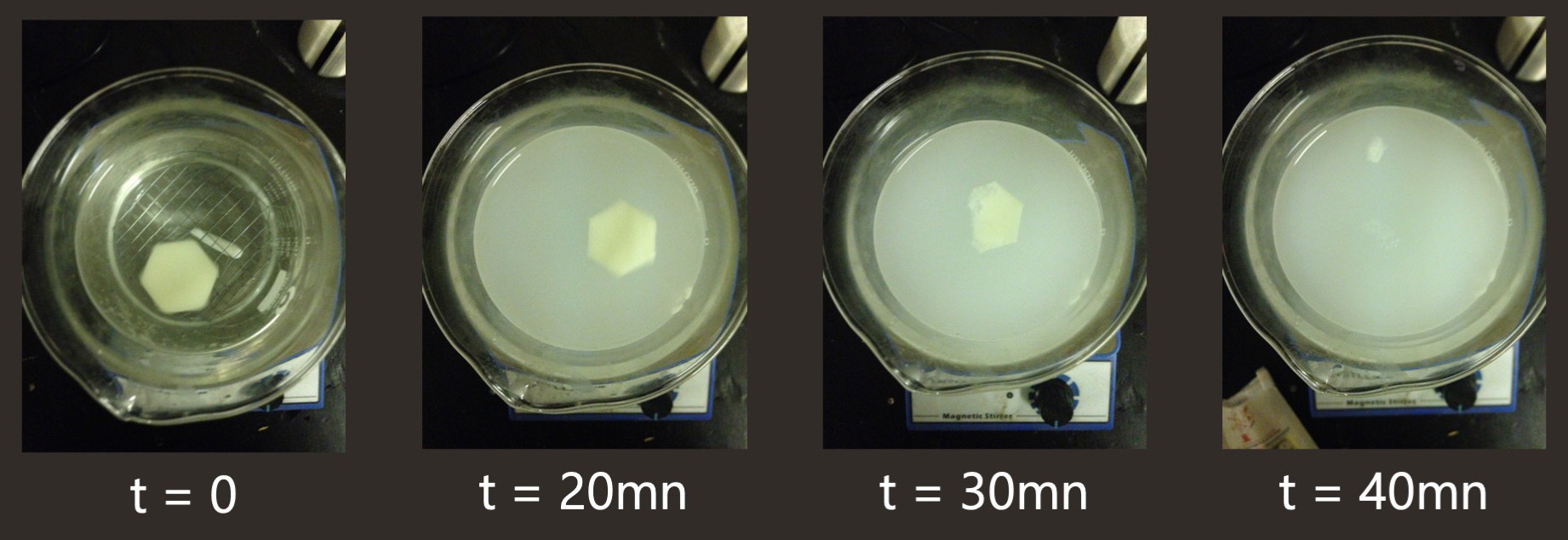

The dissolution time varies depending on the thickness of the BVOH, the temperature of the water and its agitation. The water temperature must not exceed 70°C and must be adapted so as not to damage the part to which the BVOH is attached (40 ° maximum for the PLA).

Complete dissolution of the BVOH hexagon in stirred water takes 40 minutes.

For example, a 1.5 g hexagon dissolves completely in stirred water at room temperature in 40 minutes (at 20°C), it is two times faster than PVOH.

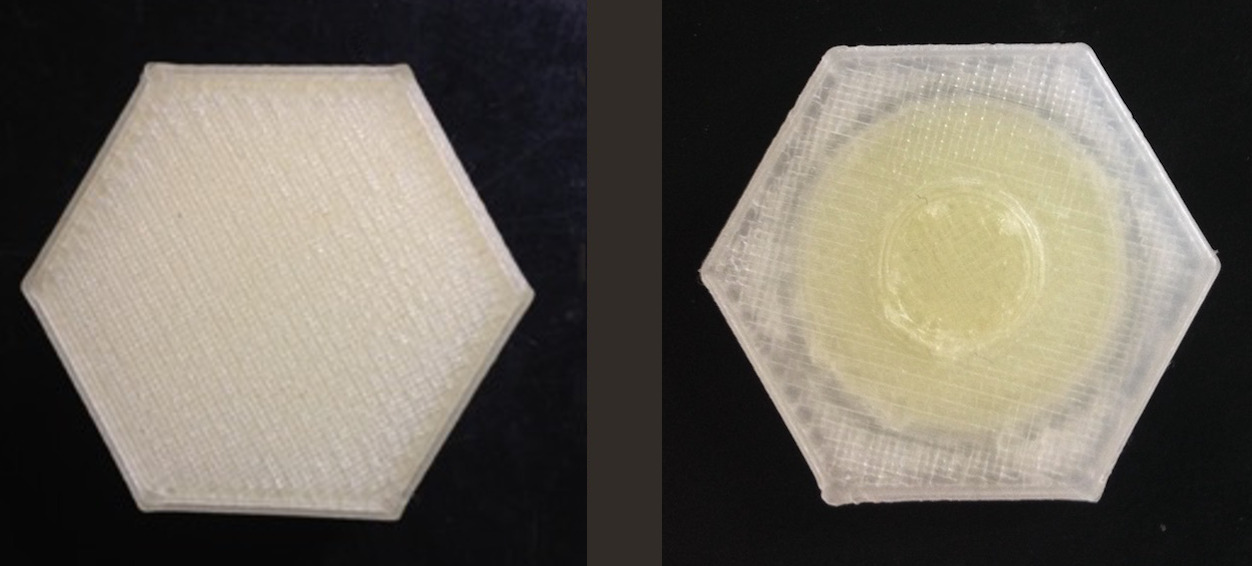

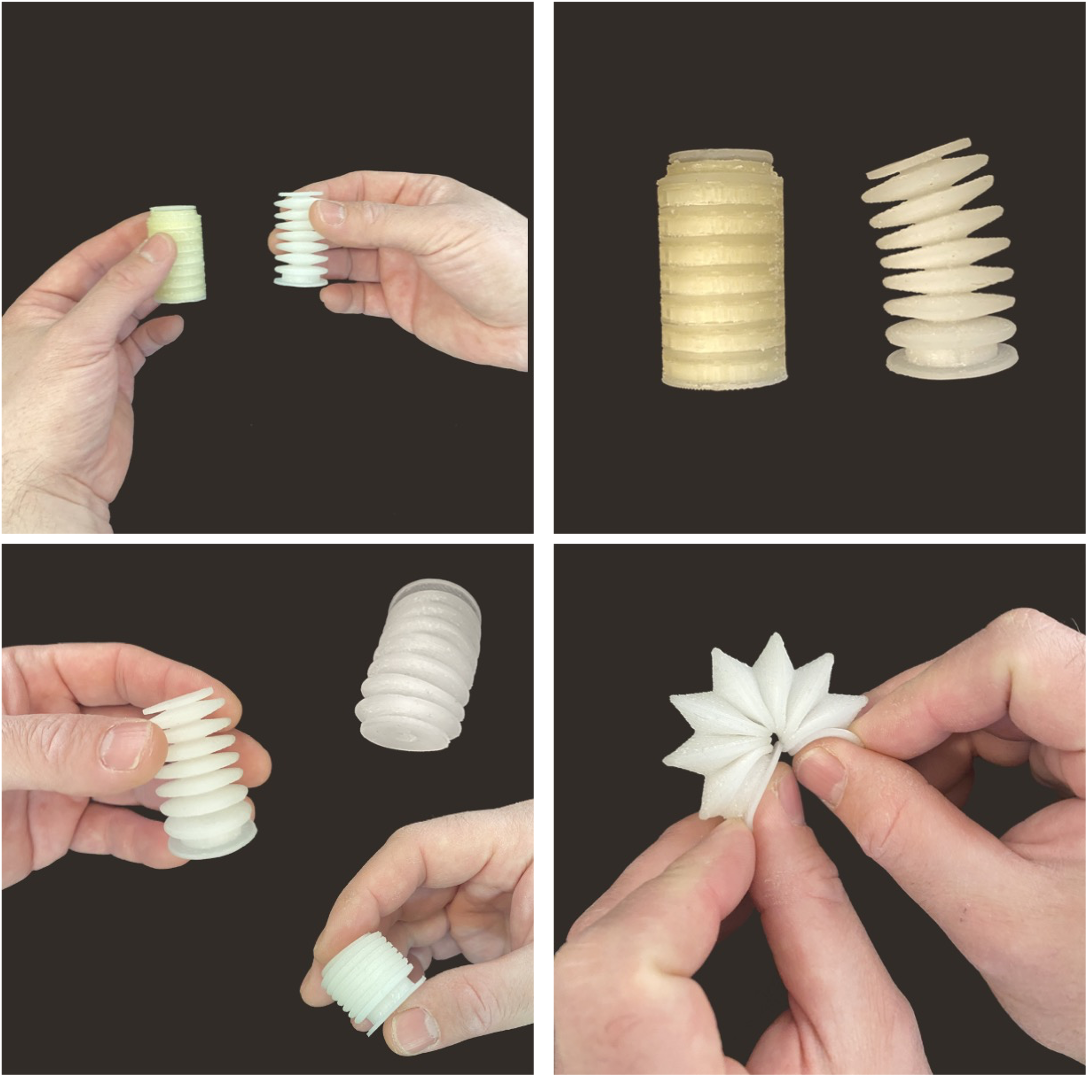

BVOH hexagon and multi extrusion hexagon in TPE 45 ShA with a BVOH insert.

While the 3D printing profile for BVOH is already defined, the one for multi-extrusions or for its use as support material is still under development. Pollen AM is currently working on the use of BVOH with TPE High Flexibility, a 45 Shore A TPE.

Bellows 3D printed with a TPE 45 Shore A and BVOH as support material structure.

To know more about BVOH compatibility contact our expert team !

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

Français

Français