PA-6-6 - Polyamide 6-6

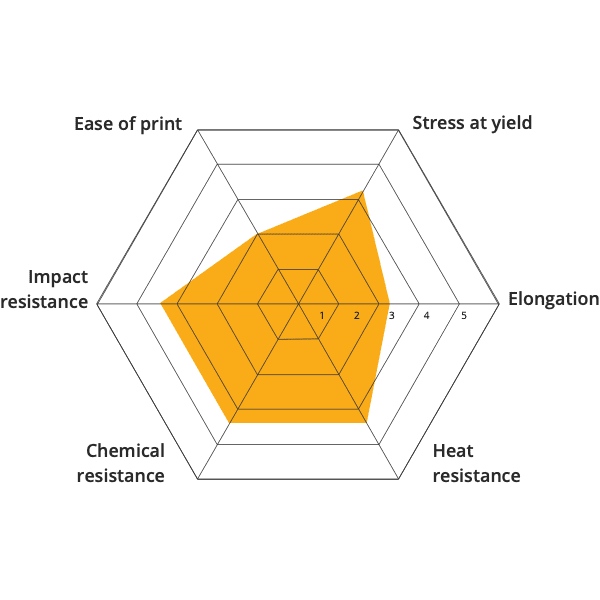

Polyamide-6-6 or poly(hexamethylene adipamide) - PA-6-6 - is a semi-crystalline thermoplastic and is the strongest unreinforced aliphatic nylon and the most resistant to abrasion and low temperatures. It has good resistance to friction and impact. PA6-6 can be alloyed with fiberglass or carbon and used as reinforcement materials.

It is successfully used in various applications in the electronics, automotive, construction, and mining industries to manufacture mechanical parts, lubricant-free gears, fan blades, etc.

Main 3D printing parameters

| Advised nozzles | Brass 0.25 | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 mm |

| Printing temperatures | 260 - 290°C |

| Buildplate substrate | PA film | Micro-perforated buildplate |

| Builplate temperature | 80 - 90°C |

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.