Mechanical Testing - Z Direction

Protocol.

When evaluating the mechanical properties of printed parts, it may be necessary to test the main printing orientations. Pollen AM offers a test protocol to evaluate the X, Y, Z45 and Z 3D printing directions.

Buildplate preparation - Z Direction

The tensile specimen is printed perpendicular to the direction of stress. This printing direction is generally the one that results in the lowest tensile strength properties.

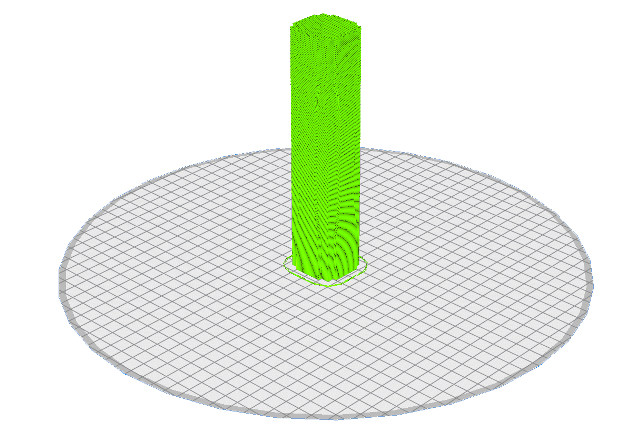

Buildplate presentation. Axonometric view

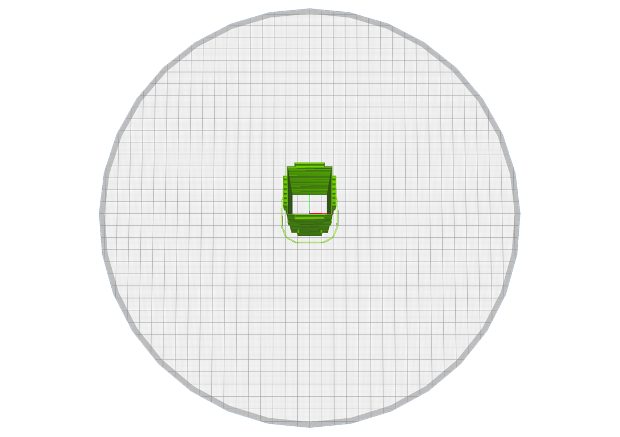

Buildplate presentation. Top view

3D printing this tensile specimen in the Z direction poses a definite risk of part vibration and thus reduces the print quality.

This is because the part has too little space on the platen in relation to its height.

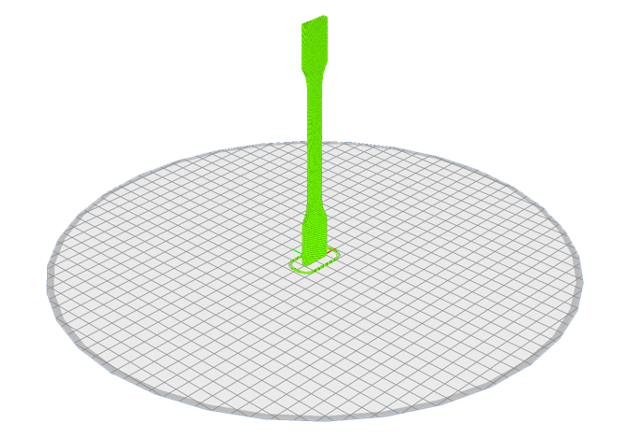

Slicing presentation. Axonometric view

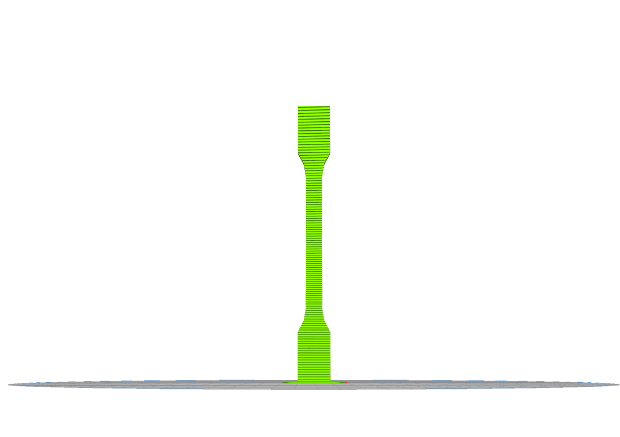

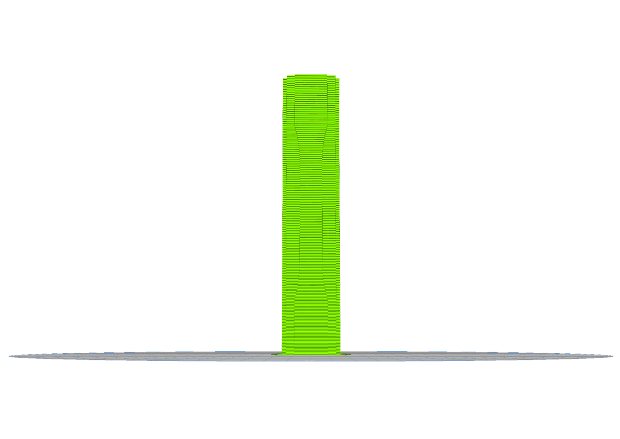

Slicing presentation. Front view

Slicing presentation. Side view

To improve the 3D printing qualitiy and part stability, the use of an optimized 3D model is recommended.

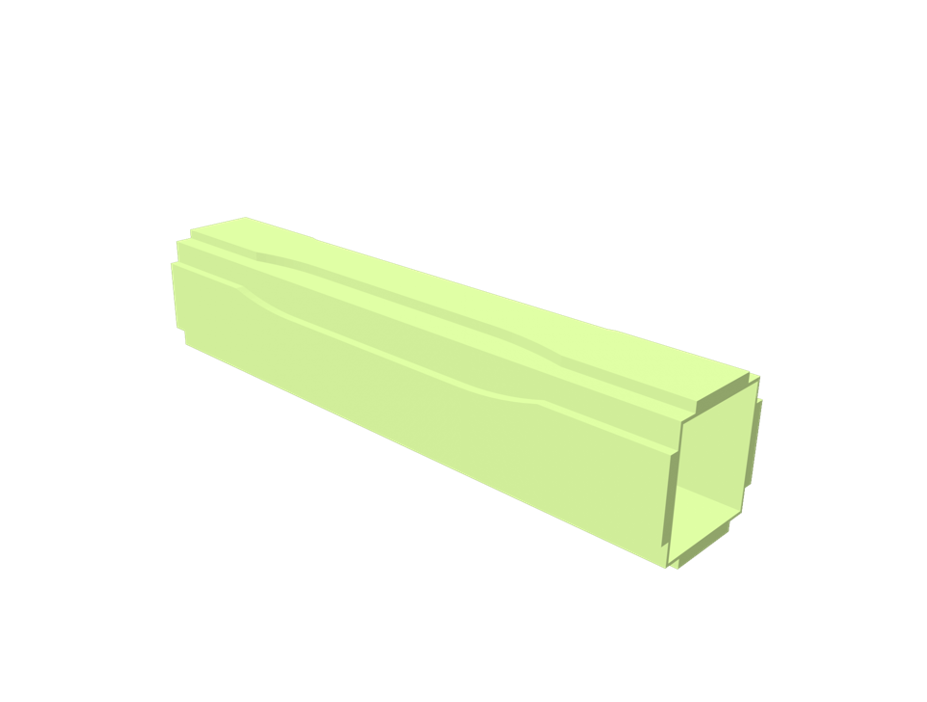

Pollen AM recommends the use of a 3D model with a square base and a tensile specimen on each side, connected by a thin wall.

This allows to avoid the vibration of the part during its production.

Slicing presentation - Optimized 3D model. Axonometric view

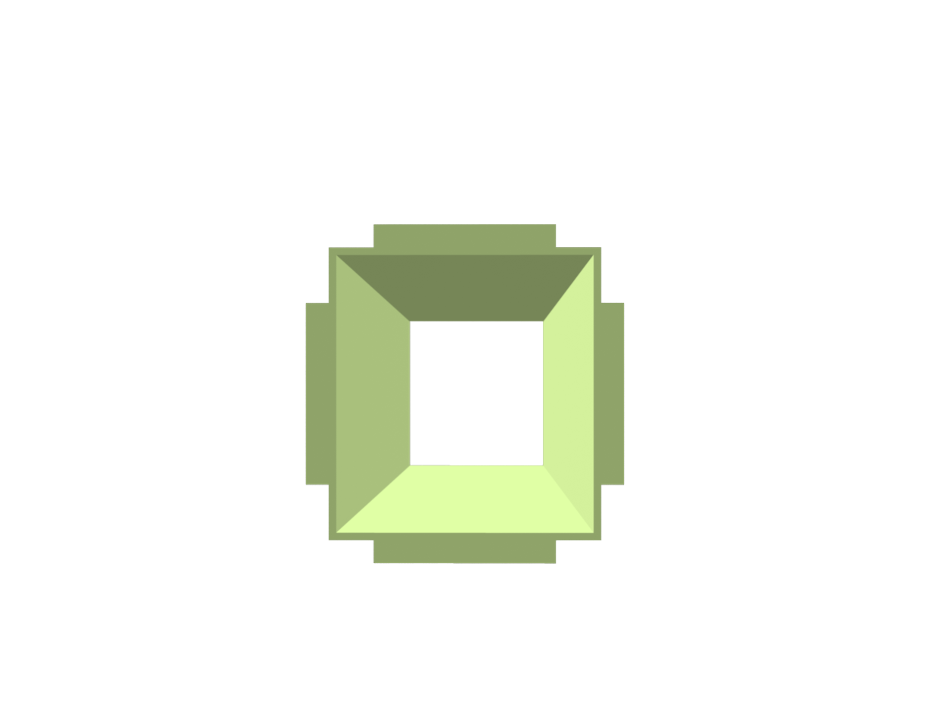

Slicing presentation - Optimized 3D model. Top view

Slicing presentation - Optimized 3D model. Front view

The infill parameters used for this configuration are :

- Infill pattern : Lines

- Infill direction : 90

- Infill density : 100

- Wall line count : 2

It is possible to test different configurations to analyse their impact on mechanical tensile properties.

Download the Type I tensile specimen

Download the Type IV tensile specimen

Download the Z tensile specimen

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.