Mechanical Testing - Y Direction

Protocol.

When evaluating the mechanical properties of printed parts, it may be necessary to test the main printing orientations. Pollen AM offers a test protocol to evaluate the X, Y, Z45 and Z 3D printing directions.

Buildplate preparation - Y direction

The tensile specimen is printed at 90° to the plane of the manufacturing plate. The material is deposited in the direction of the stress.

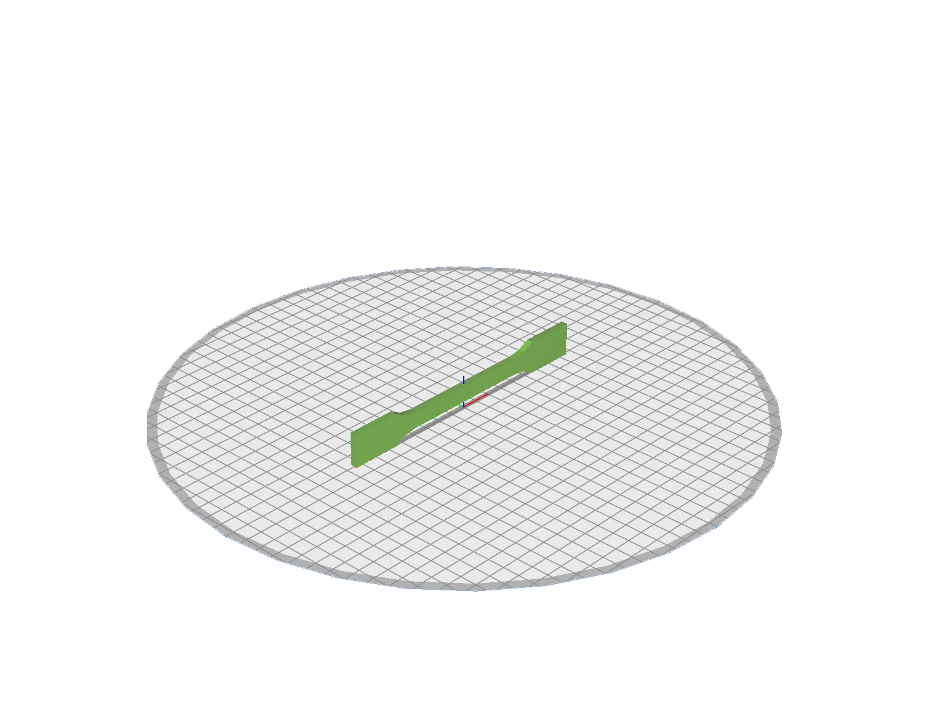

Buildplate presentation. Axonometric view

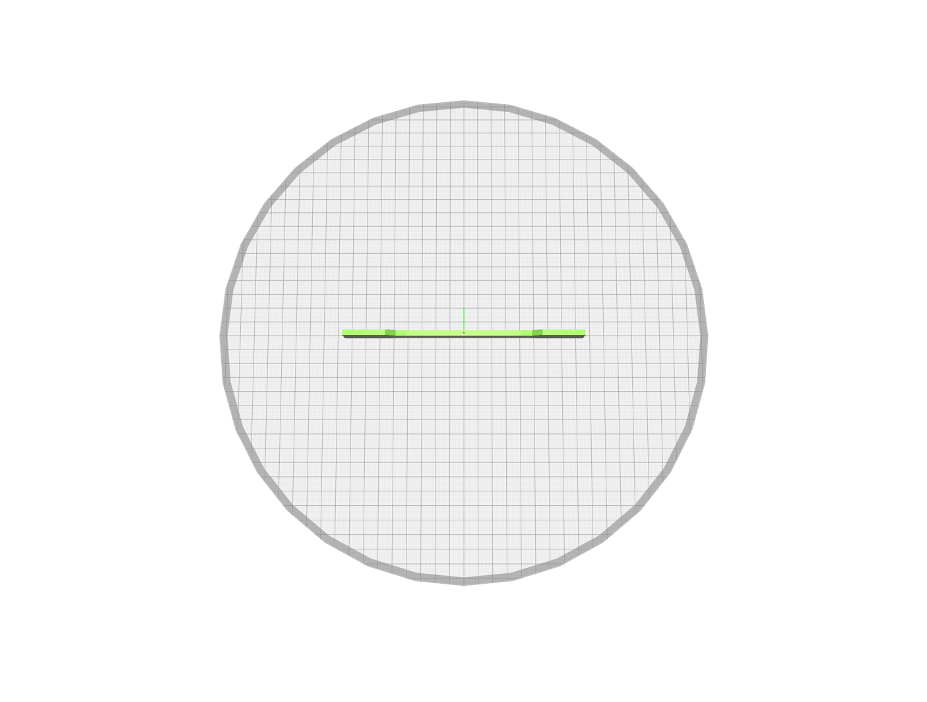

Buildplate presentation. Top view

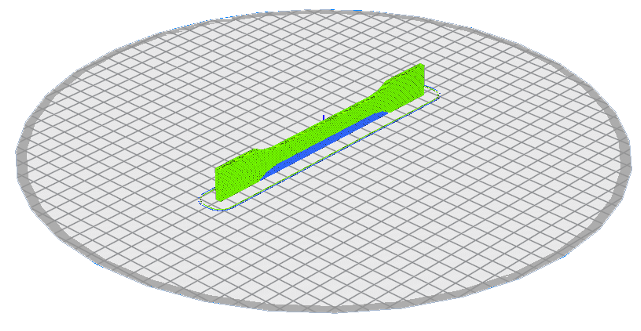

To be 3D printed, this configuration, will require a support structure material. (Blue element)

Slicing presentation. Axonometric view

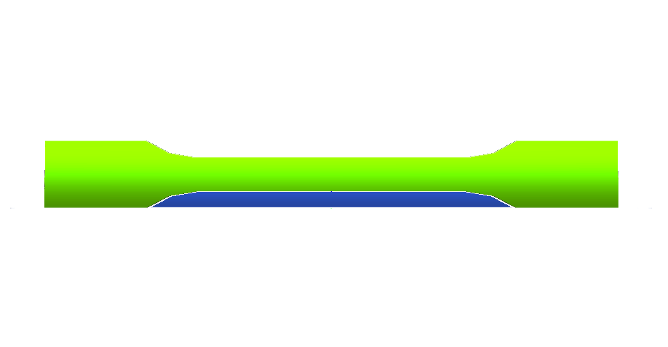

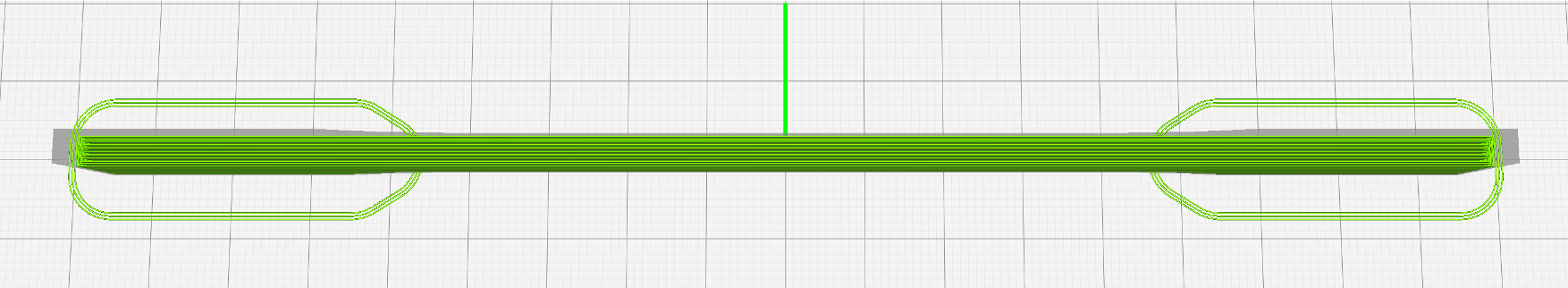

Slicing presentation. Front view

Buildplate presentation. Top view

The infill parameters used for this configuration are :

- Infill pattern : Lines

- Infill direction : 90

- Infill density : 100

- Wall line count : 2

It is possible to test different configurations to analyse their impact on mechanical tensile properties.

Download the Type I tensile specimen

Download the Type IV tensile specimen

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.