.STL file interpretation

The step before the 3D printing process.

The interpretation of the obtained file by a "Slicing" software to obtain a G-Code command file.

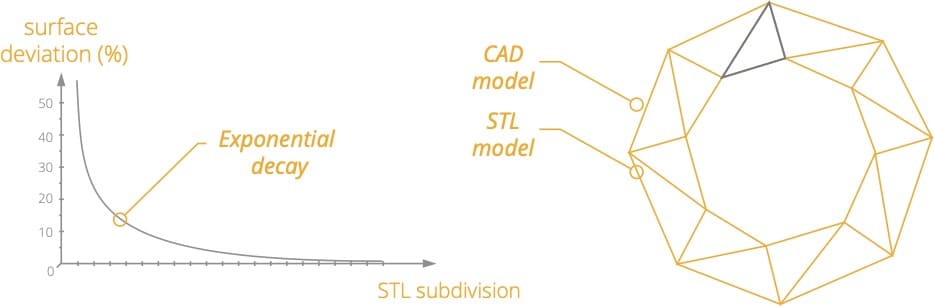

Just before the part manufacturing stage, the 3D model in triangulated format (.STL) must be interpreted into a series of instructions executable by the PAM system in G-code form.

To do this, the .STL file is imported into a cutting software (Slicer) such as CURA by Pollen AM. The cutting software generates a series of drawings of a given height (called a print layer). The slicer considers the 3D file as a surface model consisting of a skin and a filling (this element will be treated in another part).

It is during this step that the printing parameters or printing profiles are defined. It is possible to modify, for example, the thickness of the skins, the density of the filling, the layer height, the printing speeds, etc.

With a closed 3D printing solution, the user does not have access to all the printing parameters and must therefore use the manufacturer's printing parameters, without the possibility of modification and optimization.

By using so-called open solutions such as 3D PAM printers, the user has total control over the printing parameters. They can use print profiles provided by Pollen AM, make modifications and develop new ones according to the desired materials and resolutions.

In order to help the user get to grips with an open system, Pollen AM offers training and support path through an e-learning and online support platform.

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.