Encoding the surface geometry of the CAD model

Conversion to .stl format, etc.

Once the 3D model is finalized, it will have to be exported to a format that can be interpreted by the cutting software used in the next step: the Slicer.

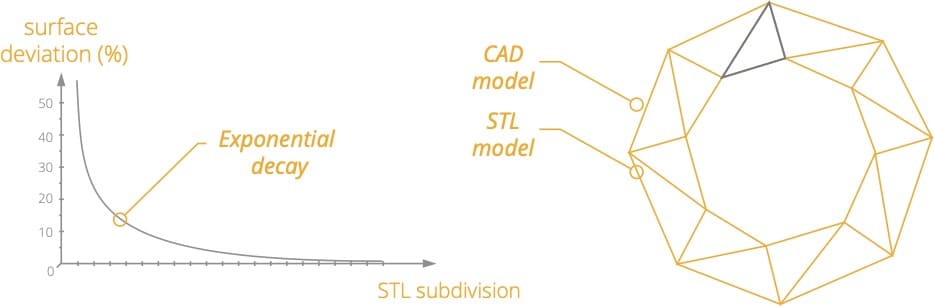

The digital chain requires the use of triangulated 3D files. A triangulated 3D model describes only the surface geometry of the 3D object. The surface of the object consists of an accumulation of triangles whose size may vary depending on the resolution to choose when converting to the triangulation format.

If the 3D model wasn't meant to be 3D printed, it could be needed to check some details, including the mesh density (also known as mesh resolution).

When exporting a 3D model, a mesh is generated. Finding the right mesh density based on the object's purpose will be necessary.

A low-density mesh will generate a 3D printed object where the faces can be observed, which isn't ideal if it's a visual element.

On the other side, if the mesh density is too high, the 3D printer and the slicing software may have issues handling the file.

Below you can see the difference between a template exported in STL format in low or high resolution.

Download the STL :

- 100mm sphere exported in 300 polygon

- 100mm sphere exported in 300 polygon

- 100mm sphere exported in 300 polygon

- 100mm sphere exported in 300 polygon

- 100mm sphere exported in 300 polygon

- 100mm sphere exported in 300 polygon

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.