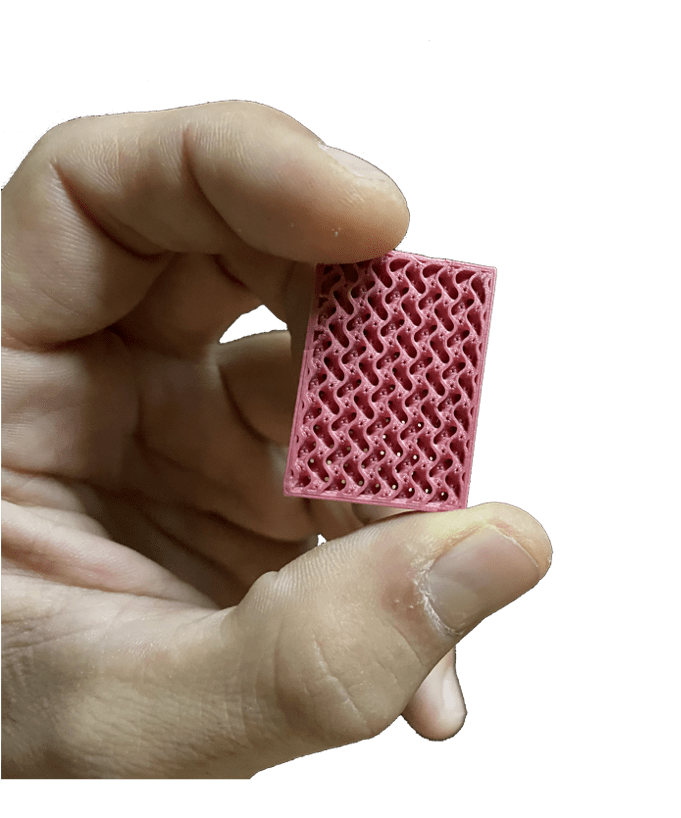

- Material research

- Multi-extrusion research

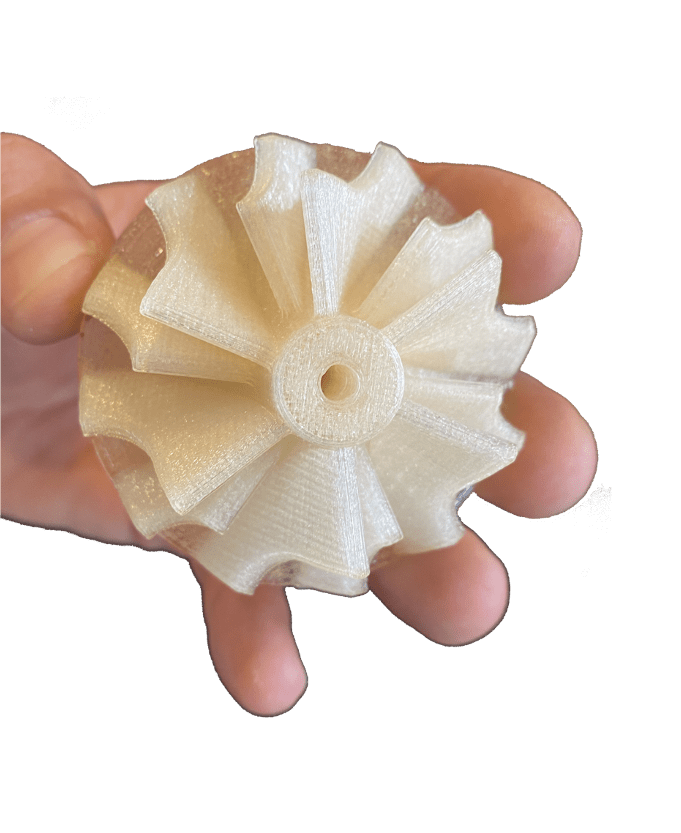

- Prototypes & concept validation

- Material validation

- Functional testing

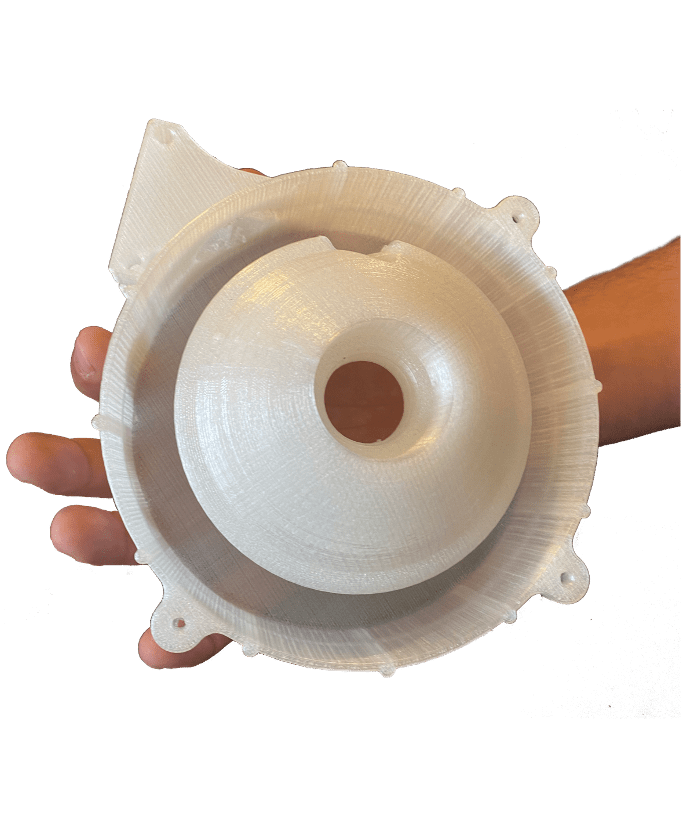

- On demand & local production

- Support to industrialization

- Tools, jigs & fixtures

- and so many more ...

Education & Research / Aerospace /

Automotive / Home appliances /

Health & medical and so many more ...

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.