Ceramic feedstocks

The most efficient materials.

pam o2 MC can print most of the existing Ceramic Injection Moulding feedstocks. You have e choice to pick the one your industry is familiar with.

Engineering ceramics materials used in technical applications satisfy extremely highly demanding applications in terms of properties ; from wear and heat resistance, temperature and corrosion resistance to biocompatibility and food compatibility.

This vast range of properties make it possible to use technical ceramics in a large variety of applications.

Using standard CIM feedstock with the Pam Technology particularly makes sense for industrial already used to them. Existing grades can be printed as-is at their unbeatable high volume price.

PIM feedstock classification

From oxide ceramics to non-oxide ceramics.

Pam Series MC is 3D printer dedicated to print industrial PIM feedstocks; from metals to technical ceramics.

pam o2 MC is open to materials, consumables are widely available in their industrial format, the pellets. It is this technological difference that gives access to the widest library of CiM materials on the market.

Technical ceramics fall into three different categories:

- oxides: aluminium oxide, zirconium oxide;

- non-oxides: carbides, borides, nitrides, ceramics composed of silicon and atoms such as tungsten magnesium, platinum or even titanium;

- composite ceramics: combination of oxides and non-oxides.

As a dedicated technology inspired by micro-extrusion techniques, Pam Technology is meant to 3D print most kinds of PIM feedstocks.

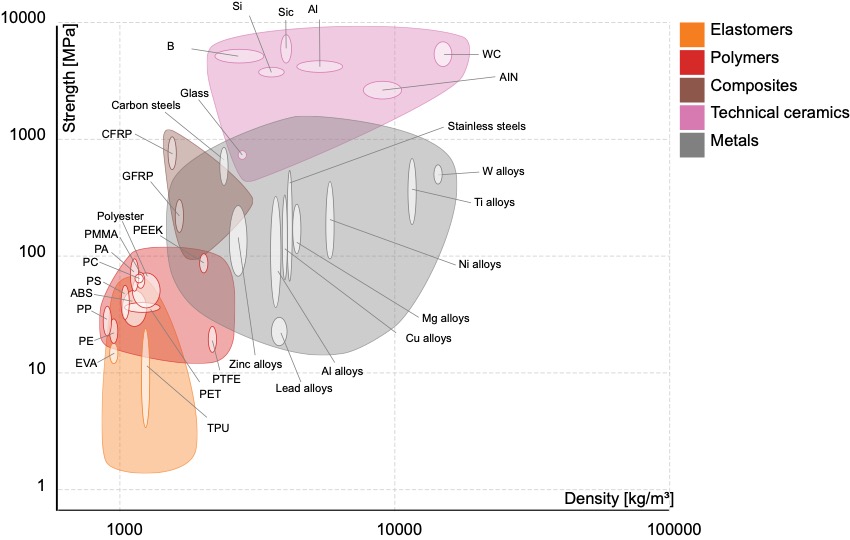

Materials are usually classified into different categories according to their nature and their mechanical properties such as their Young's modulus, etc.

Discover Metal and Ceramic 3D printed parts

Français

Français