Focus on material cartridge

Adaptable & refillable on the fly.

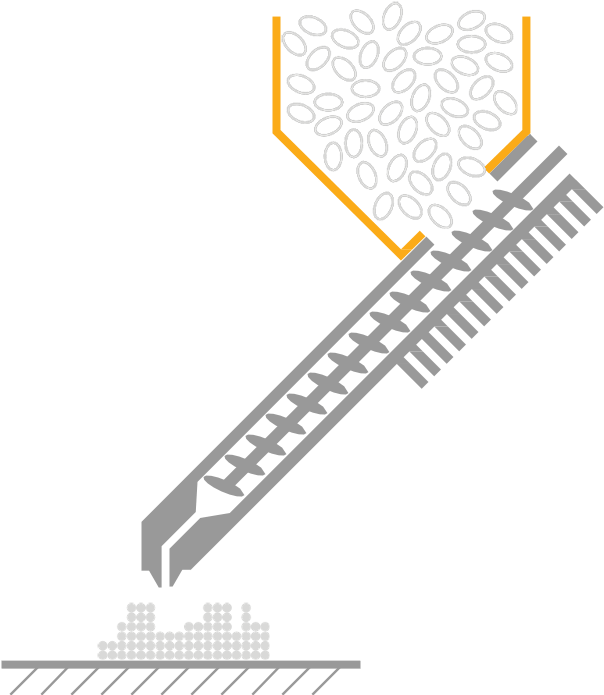

The material cartridge contains ±1L of pellets, it can be reloaded during the production cycle if needed.

Different versions of the material cartridge are available depending of material to work with.

A feeder is integrated to ensure pellets are correctly running down by gravity into the extruder.

Material specifications compatible with Pam systems:

- Materials: injection molding grade (thermoplastics, metal & ceramic feedstocks);

- Maximum viscosity: 6 000 Pa.s at negligible shear and process temperature;

- Processing Temperature: 30°C – 450°C*;

- Pellet size: 2 to 4 mm;

- Granulometry: head cutting or cold cutting;

- Possible filler: fiber, mineral, natural and up to 60% in volume;

- Supplier: Open.

* Depending on Pam 3D printers.

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.