Focus on heating room

To enhance 3D printed performance materials.

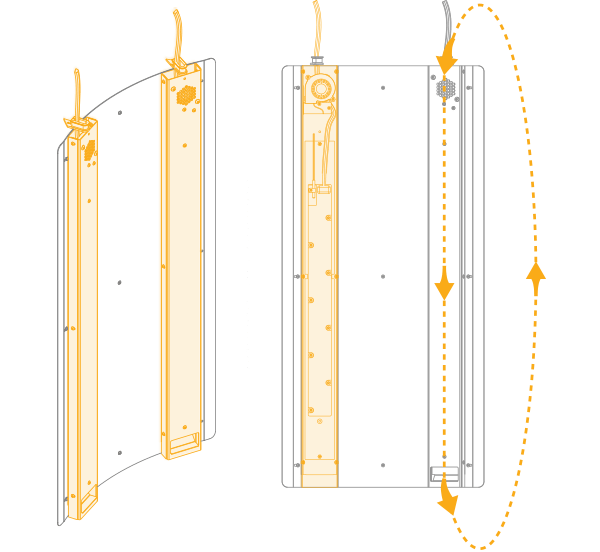

The building room chamber can be heated thanks to the heating room and radiant disc accessories.

The heating room maximum* reachable temperature is 80°C in order to prevent possible distortions induced in the 3D printed parts. This accessory is particularly useful when processing materials that may have a tendency to warp and require the manufacturing environment to be controlled and maintained at a specific temperature.

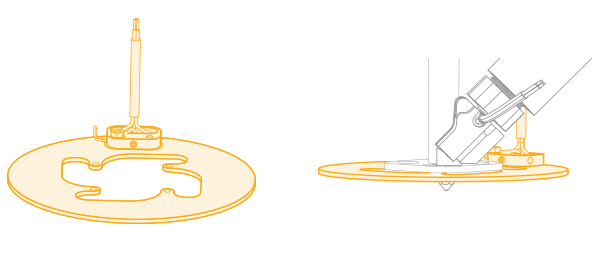

A local radiant disc is also present in the 3D printer*, this equipment has the capacity to heat up to 350°C. It allows maintaining the last 3D printed layers at a specific temperature, improves interlayer adhesion, allows a better management of the recrystallization of materials (semi-crystalline) and also limits the "warping".

Not all materials require the use of the heating chamber or the radiant disc to be 3D printed.

Room temperature of the building envelope can be adjusted in function of material physical properties*.

* Depending of Pam 3D printers configuration.

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.