Focus on extruder

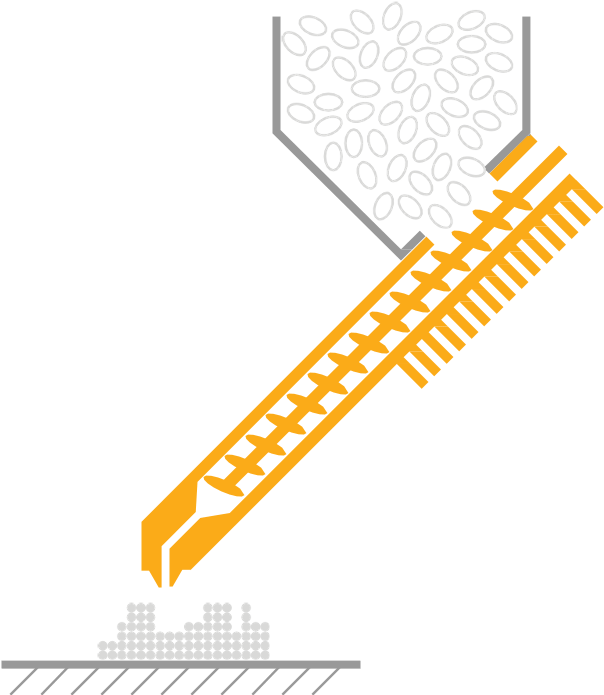

Micro-extrusion adapted to 3D printing.

Pam extruders are composed of proprietary cylinder, Auger screw and extruder die, heating elements, fans, thermocouples, etc.

Rotation of the Auger screw is controlled: the material flow is directly linked to the screw speed retract function is assured by inverted screw rotation.

This is not a resizing of existing technological process: The screw L/D ratio induces particular material behaviour. Hence, screw profile, temperature control and the whole process are unique and specially designed by Pollen AM for Pam technology.

Extruder specifications:

- Extruder volume: < 8 cm3;

- Maximum extrusion speed: 22 rpm;

- Alloy: nitruded steel;

Extruder shear: Low or High*.

* Depending on Pam 3D printers.

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.