PPS - Polyphenylene sulphide

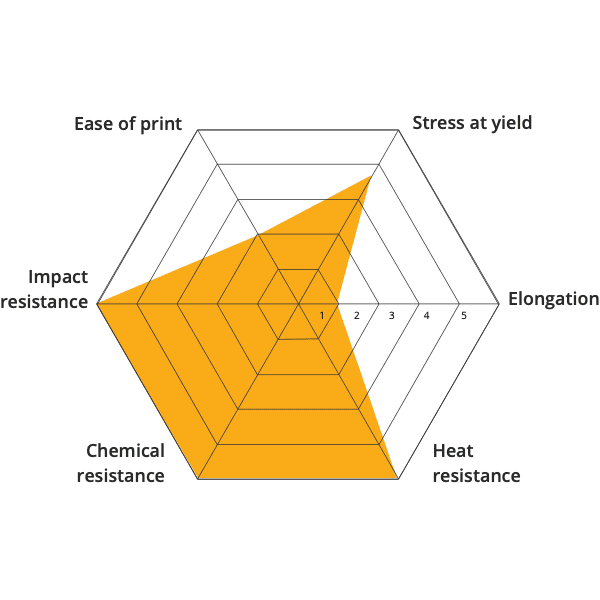

Polyphenylene sulphide (PPS) is a high-performance thermoplastic. Maximum service temperature is 218 °C. PPS has not been found to dissolve in any solvent at temperatures below approximately 200 °C.

An easy way to identify the compound is by the metallic sound it makes when struck.

PPS is used in filter for boilers, electrical insulation, capacitors, gaskets, and packing.

Main 3D printing parameters

| Advised nozzles | Brass 0.25 | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 mm |

| Printing temperatures | 300 - 350°C |

| Buildplate substrate | HT buildplate |

| Builplate temperature | 110 - 150°C |

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.

Français

Français