Tool Steel – M2 (1.3343)

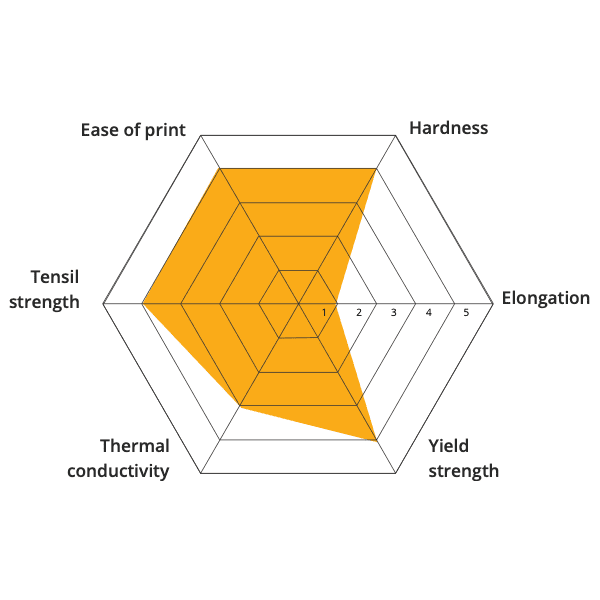

M2 steel is the "standard" and most widely used industrial high-speed steel, commonly used as cutting tool material. It is often used in power-saw blades and drill bits. After heat treatment, its hardness is the same as T1, but its toughness and thermo-plasticity are higher than T1 by 50%.

It is usually used to manufacture a variety of tools, such as drill bits, taps and reamers.

Composition

| Element | Si | Mn | S | P | V | W | Ni | Mo | Cr | C | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Content | 0,2 - 0,45% | 0,15 - 0,4% | 0,03% max | 0,03% max | 1,75 - 2,2% | 5,5 - 6,75% | 0,3% max | 4,5 - 5,5% | 3,75 - 4,5% | 0,78 - 1,05% | Balance |

Discover Metal and Ceramic 3D printed parts

Français

Français