PMMA - Poly(methyl methacrylate)

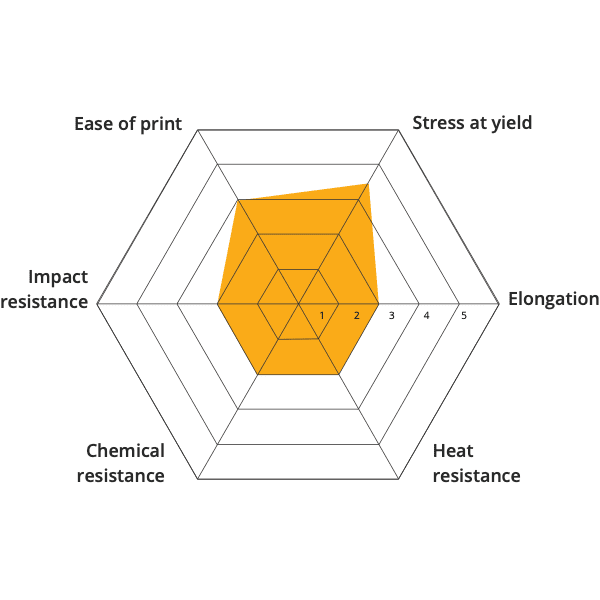

Poly(methyl methacrylate) - PMMA - is an amorphous polymer with good balanced properties. Considered as a commodity thermoplastic, PMMA is mainly used for its optical transparency and elevated insulation properties (thermal, acoustic and electrical).

Widely used for optics, households, automotive, lighting and medical applications.

Main 3D printing parameters

| Advised nozzles | Brass 0.25 | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 mm |

| Printing temperatures | 240 - 280°C |

| Buildplate substrate | Adhesive helper | Micro-perforated buildplate |

| Builplate temperature | 50 - 80°C |

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.