Material qualification

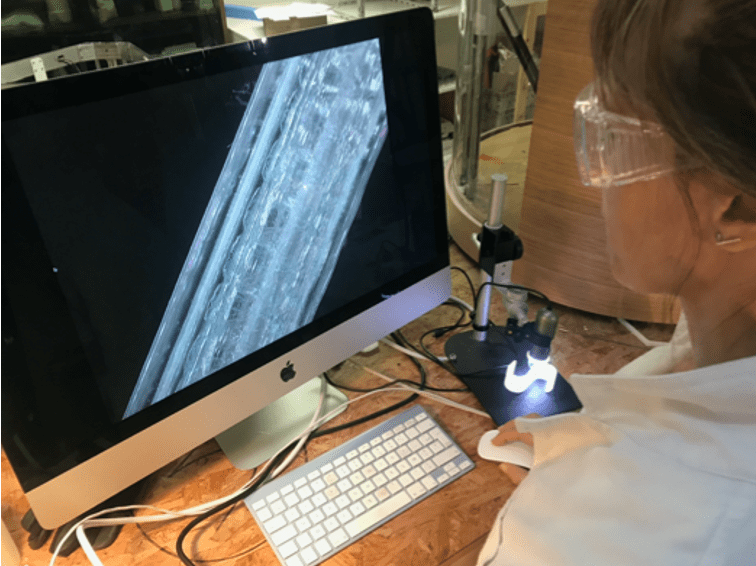

Preliminary material analysis.

The material qualification corresponds to the empirical study of the behaviour of a material during its transformation by a Pam 3D printer.

Indeed, the dimensions and the design of Pam extruders induce a particular behaviour of the material.

Objectives: The study of this behaviour to elaborate recommendations on the machine parameters and resolutions (nozzle diameter, layer height) that can be used, depending on your project and applications.

The realization of the service is made from:

- 5 kg of the material to be qualified provided by the applicant;

- all the technical documentation of the material (MSDS, TDS, Process guidelines, etc.).

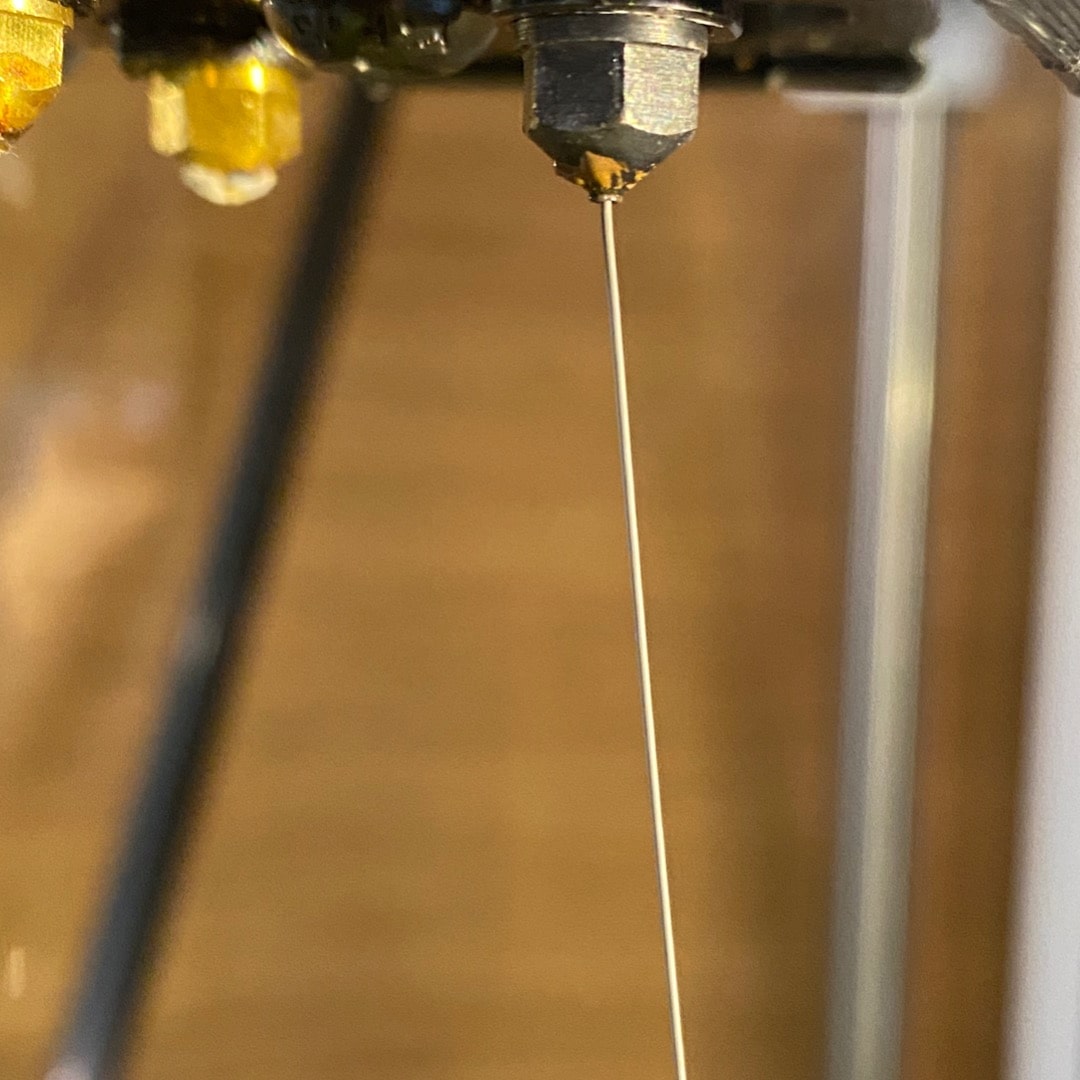

Observation of free extrusion behaviour (no nozzle mounted).

Observation of the extrusion behaviour (nozzle mounted)

The service concludes with the delivery of a technical report including :

- The range of values of the parameters to be used for a profile development;

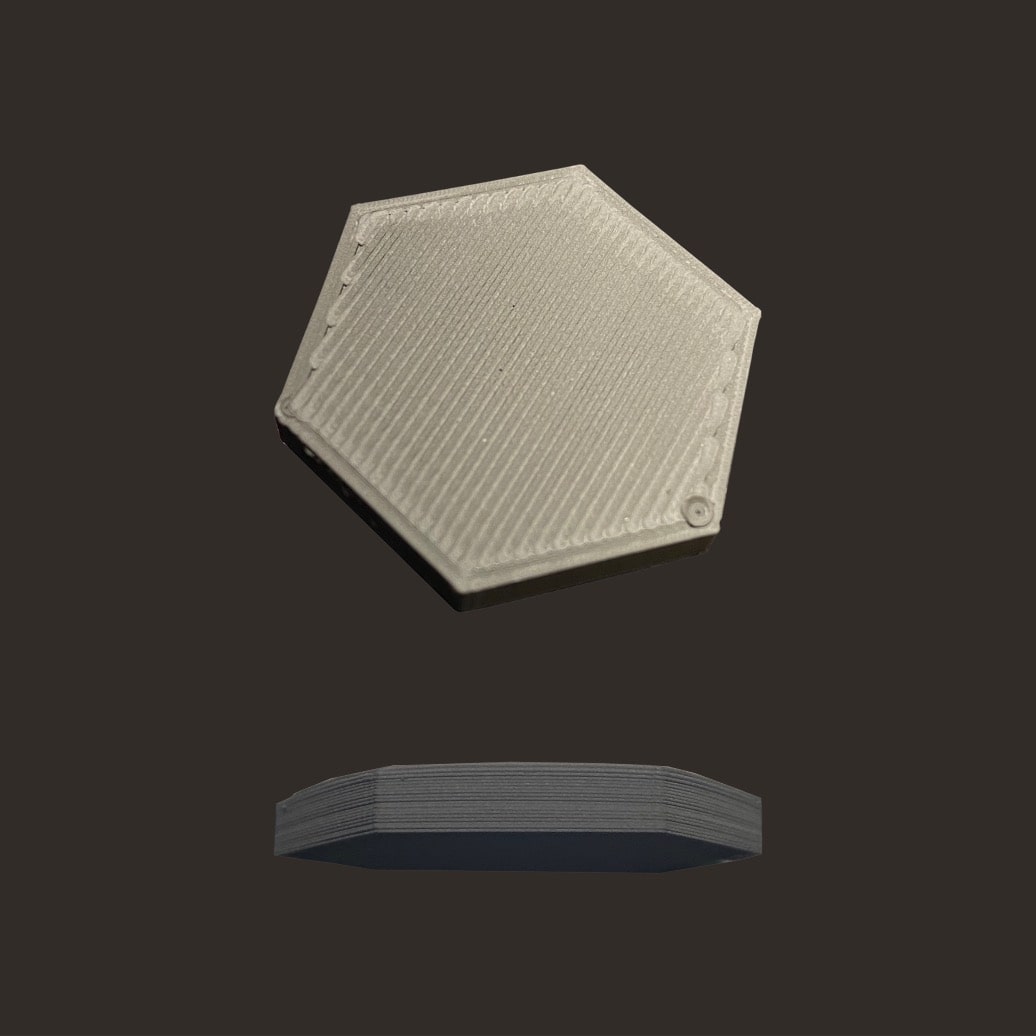

- The presentation of the compatible output nozzles and the achievable resolutions after profile development;

- A study of the level of interlayer adhesion.

Observation of the extrusion behaviour (nozzle mounted)

Finally, a hexagon is produced at the end of the qualification. This printing demonstrates the ability of the Pam system to shape the material and presents the material aspect.

Let’s dive into the possibilities offered by PAM

From pellets to object, PAM technology offers the most direct process to high performances end-parts.

Metals Ceramics Commodity Elastomers Performance High Performance.