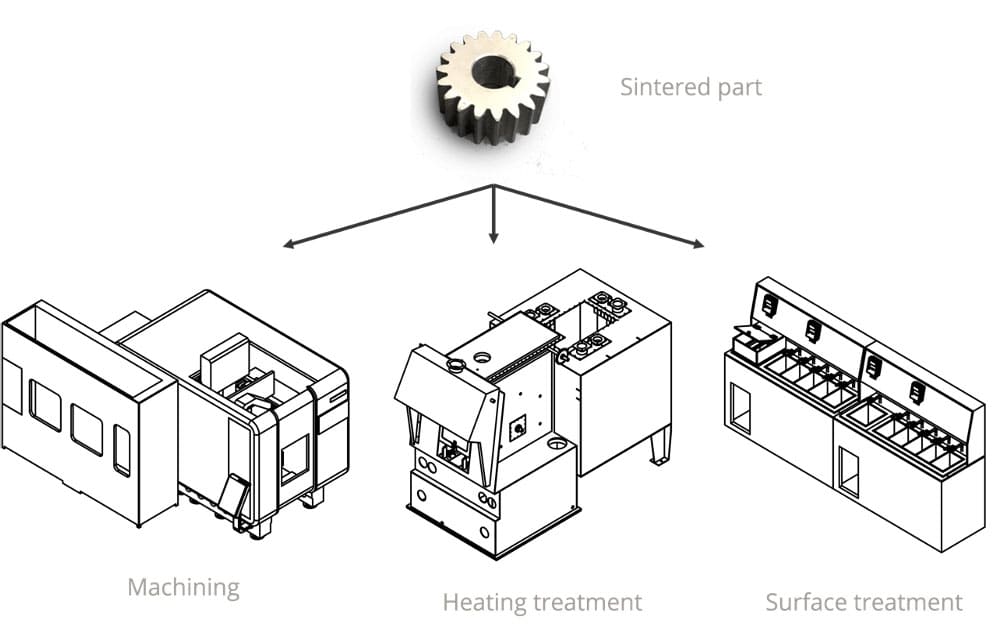

Secondary operations

Post-process costs

Classic industrial processes are compatible with sintered parts.

These costs are often very significant:

- tumble deburring / finishing;

- thermal treatment (quench & temper, ageing, etc.);

- plastic deformation (coining, sizing, straightening, etc.) ;

- machining (taps, threads, milling, turning, grinding, etc.).

- Sometimes even 50% of part total cost;

- Sometimes not carried out at the MiM producer, increase cost by adding transportation (and introduce external variables in production times);

- The golden rule is to try to avoid these costs in the first step, by optimising the design (e.g. avoiding “over tolerancing”);

- Dealing with small parts, often an initial cost for the setup of the operation (small tools for handling, etc.) adds to the cost per part;

- These costs do not reduce with lot size as much as MiM costs (less dependent on quantity).

Discover Metal and Ceramic 3D printed parts