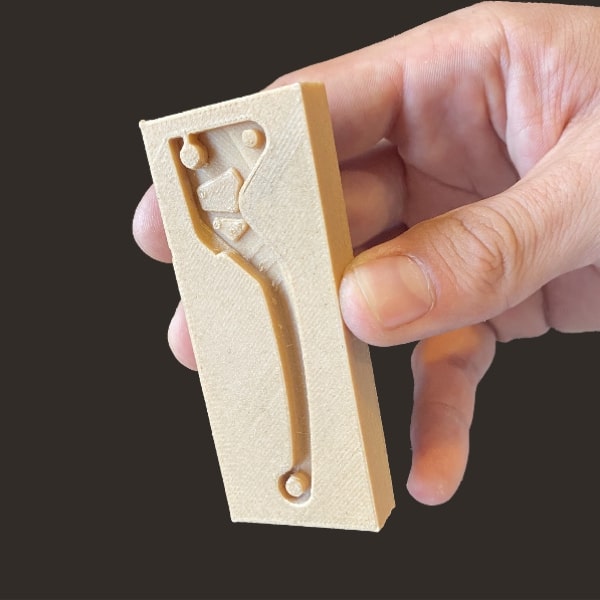

Brake Handle Mold

Part presentation

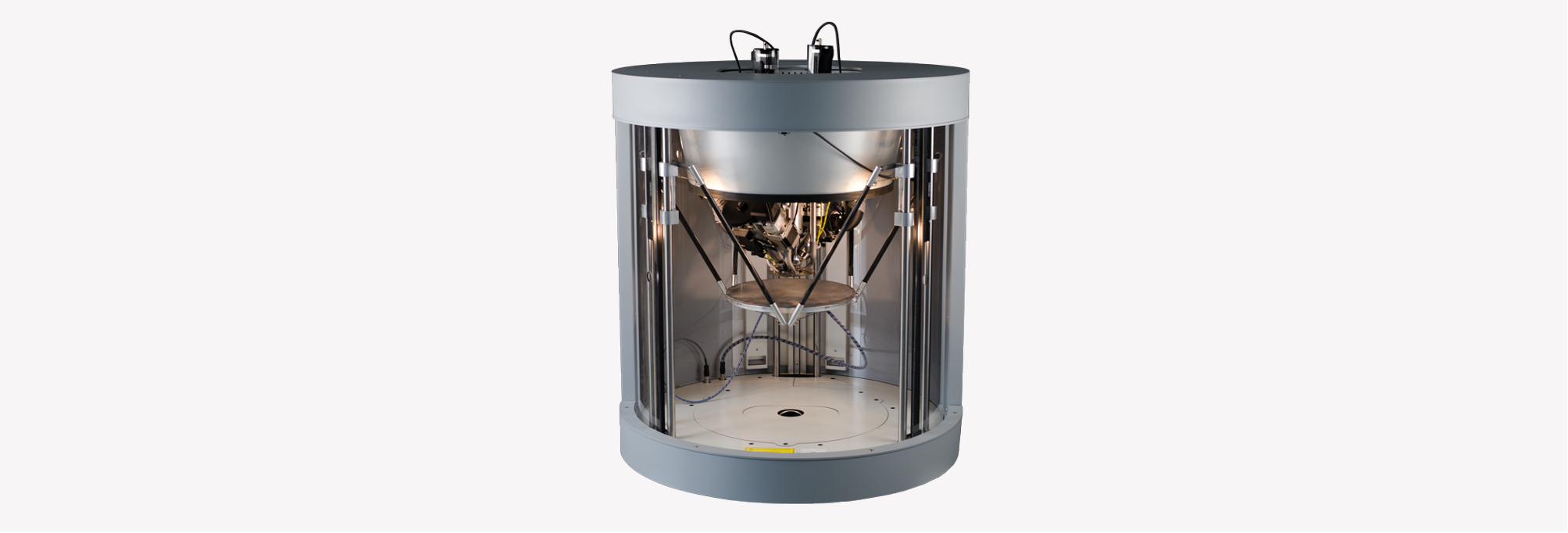

Manufactured on pam o2, this is a prototype mold made of PLA filled with 30% of wood fibers. The use of wood filled material was of interest in order to mitigate the inner layers of the mold. Printing this part helped to quickly assess it in order to run iterations inexpensively.

Material information

- Supplier: Pollen AM

- Material: PLA

- Grade: PLA Woodfill

Français

Français