It's about "PIM-Like",

but with the right material.

- Material research

- Multi-extrusion research

- Prototypes & concept validation

- Material validation

- Functional testing

- On demand & local production

- Support to industrialization

- Tools, jigs & fixtures

- and so many more ...

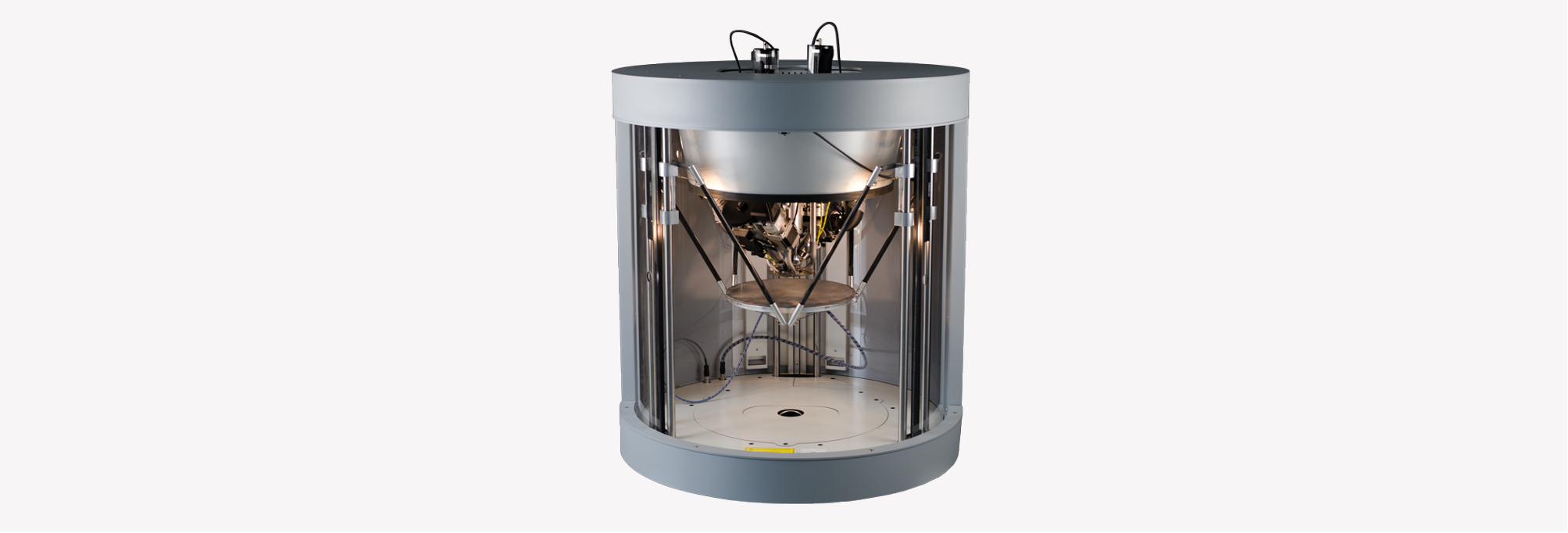

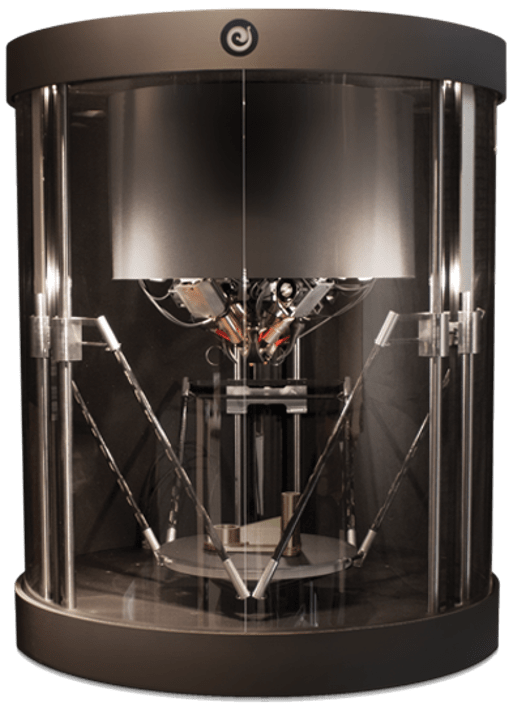

3D printer specifications

Physical Dimensions

| Diameter | 834 mm |

| Height | 925 mm |

| Weight | 95 Kg |

Main specifications

| 3D printing process | PAM |

| Number of extruder | 2 to 4 |

| Compatible materials | Metal & Ceramic feedstocks (Injection moulding grades) |

| Maximum print volume | Ø 300 x H 300 mm |

| Nozzles sizes | Ø 0.25 - 0.40 - 0.60 - 0.80 - 1.00 - 1.20 |

| Stepper motor resolution | 40µm (Z) and 5µm (X,Y) |

| Maximum extrusion temperature | 450°C |

| Maximum print bed temperature | 150°C and 250°C in options |

| Heating room | up to 70°C |

| Radiant disc | up to 300°C |

| Supplied Software | Honeyprint & Cura by Pollen AM |

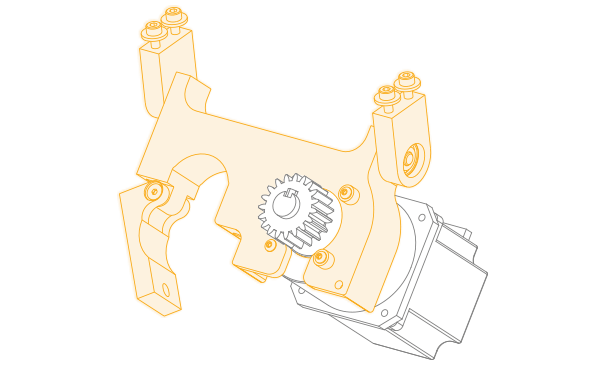

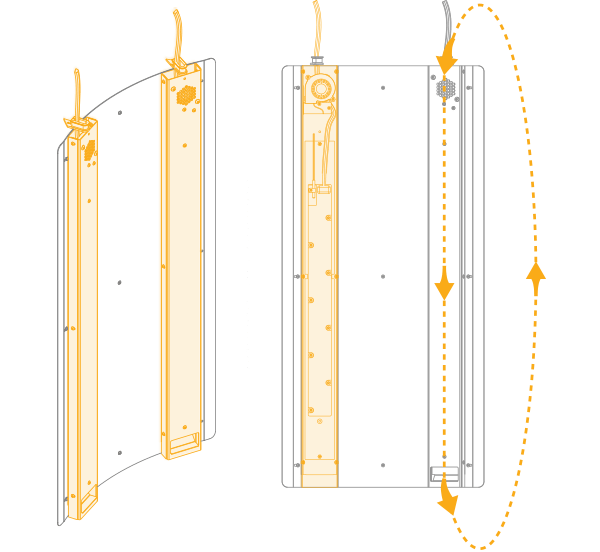

Print head

Our print head is redesigned for better visual control precision and durability.

We also improved the cooling architecture.

Fortified holding mechanism

One screw opening mechanism for easy extruder removal.

Reinforced machined aluminium parts with ball bearings integration for more precision and durability.

Optimized lifting mechanism

All in-one stainless steel wire rope with eyelets and easy one screw removal for maintenance.

Enhance material cartridge

Integrated cartridge opening mechanism for pellets refill on the fly. The hopper has an optimized base geometry for increased cooling performances and better pellets flow.

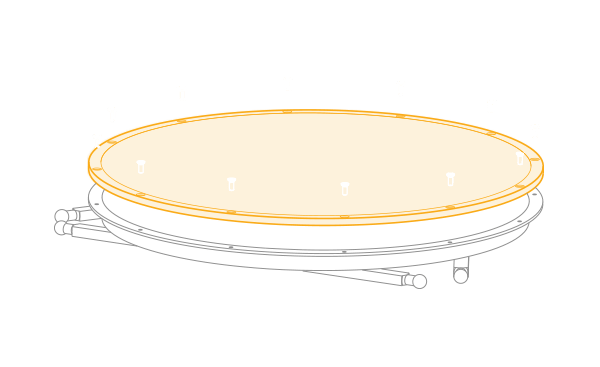

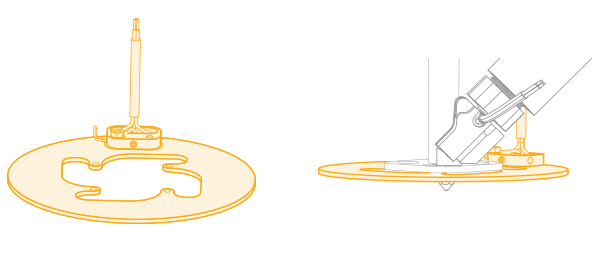

Lightened & Fortified Build Plate

Our build plate is redesigned for better maintenance durability

and dimensional accuracy.

Reliable Assembly Configuration

Easy build plate replacement and micro-perforated options dedicated to materials with strong warping effect.

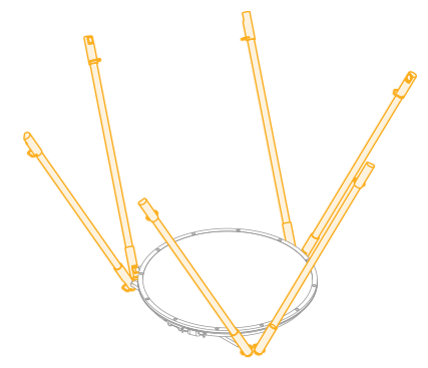

Stronger Carbon Rods

Assembly jigs are redesigned for improved carbon rods dimensional accuracy resistance and repeatability.

Enhance Heating

Two additional equipments are present to perform good temperature homogeneity into the build chamber and to optimize inter layer adhesion.

Integrated Heating Radiant Disc

Our interlayer heating device is designed to increase Z direction mechanical performances. It keeps a warm zone over the part and preserve good adhesion between each layer.

New Heating Room

Specially designed forced convection heating room devices: hot air is recycled from inside the build volume for increased thermal regularity.

Heating room temperature control is integrated in Honeyprint software for easy set-up. The maximum temperature is 70°C.

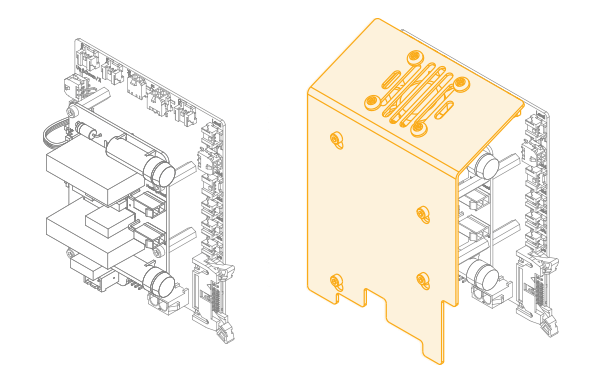

Optimized Electronics and Wiring

Each extruder is controlled by two electronic boards. One is dedicated to low-voltage heating elements and the second is dedicated to extra-low voltage such as motors, fans and temperature sensors.

Pam Series MC wiring is redesigned for increased robustness and 3D printing repeatability.

New Metal Skin

Pam Series MC has a brand new metallic and insulated casing.

In regards of improving thermal regulation and increasing maximum room temperature, we completely rethought our position towards new casing materials. Insulation plates are made out of glass wool and overlapping casing is in aluminium. This enables the best heating performances for the build volume and rapid rise in temperature.

3D printing industrial PIM feedstocks

is possible!

From metals to ceramics.

Discover Metal and Ceramic 3D printed parts

Français

Français