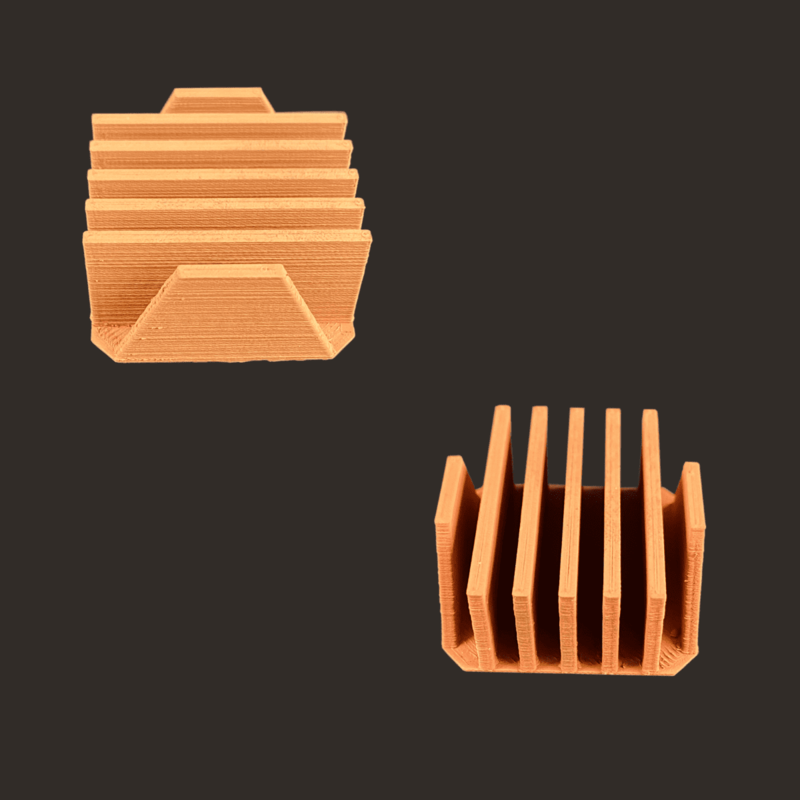

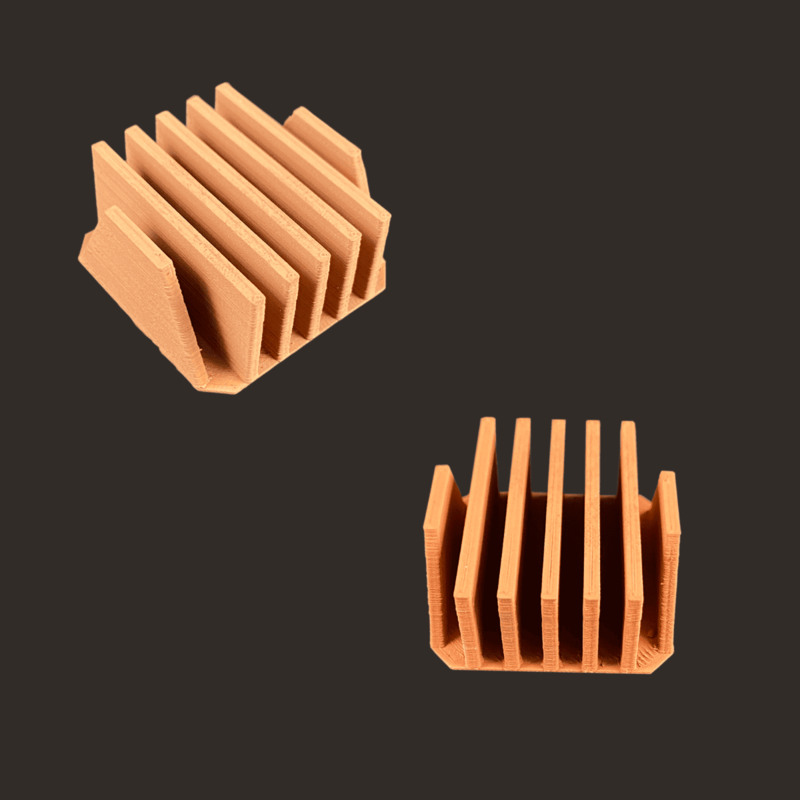

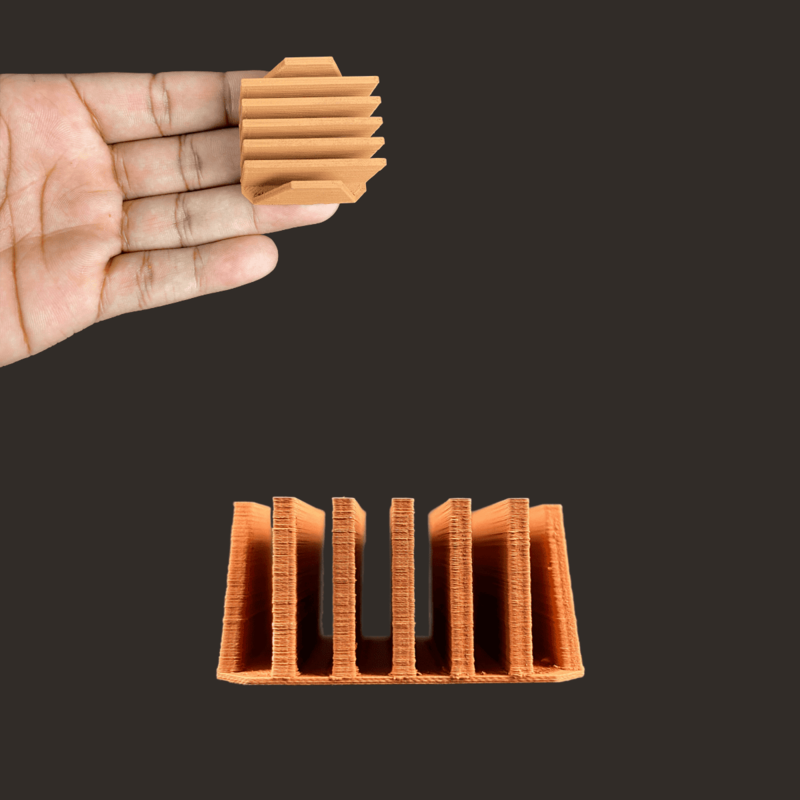

Cooling fins - Copper 999

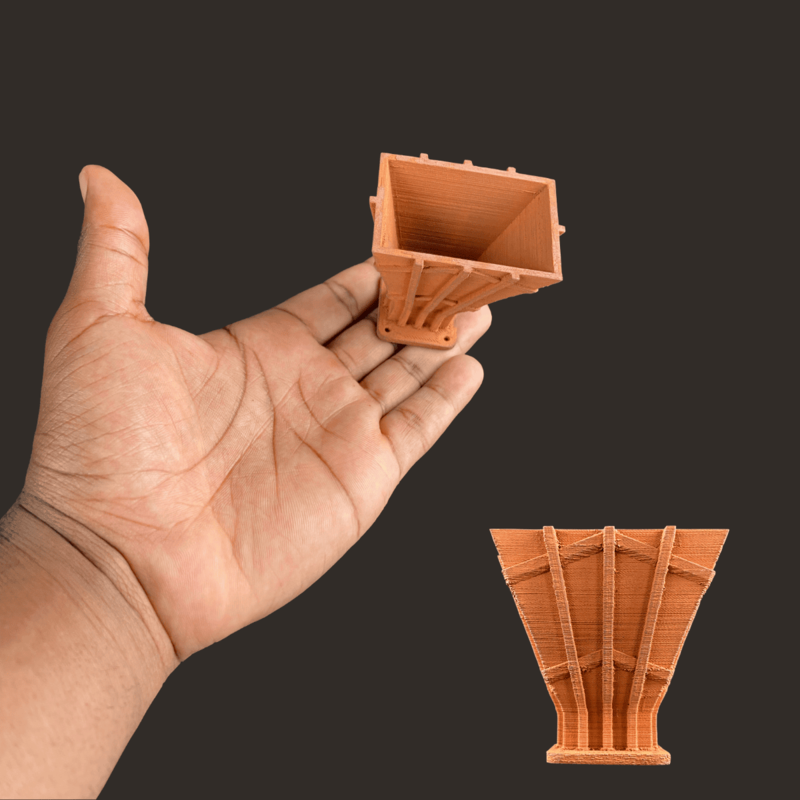

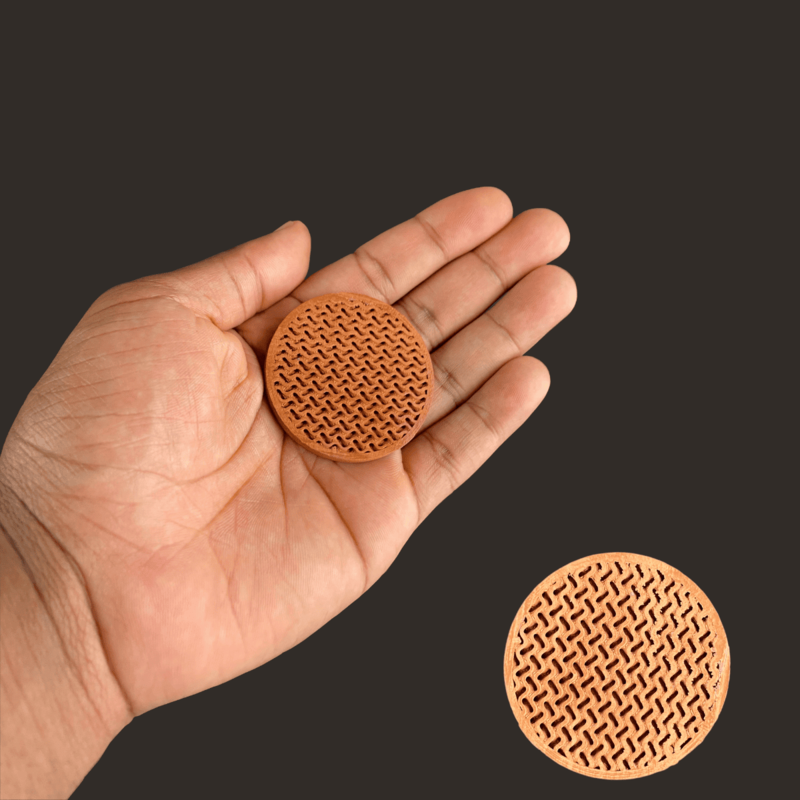

Part presentation

Cooling fins printed in Copper 999 MIM feedstock with a pam o2 - MC, offer an efficient, customized cooling solution for applications requiring high heat dissipation.

3D printing of copper feedstock enables custom cooling fins to be designed and produced, with geometries of varying complexity and shapes optimized to maximize heat exchange surface area.

Using the powder metallurgy (MIM) process, it is possible to obtain high-density, precision copper parts, offering enhanced thermal conductivity.

What's more, 3D printing enables parts to be validated before injection, reducing development and production costs.

Designs can be tested and optimized directly on the pam o2, before going into series production. This also enables mold production to be anticipated, by identifying and correcting any design problems before the mass production phase. In short, 3D printing cooling fins in copper MIM feedstock offers design flexibility, good part quality and reduced development and production costs.

Discover 3D printed parts in Copper