Pellet Additive Manufacturing at its finest

Accurate temperature control

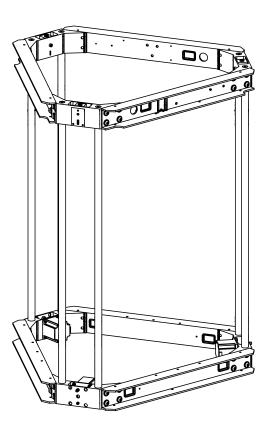

Robust mechanical architecture

Open programming & automation

pam o2 3D printers

Configurable to suit your projects

Adapt your system to your application with specific extruders, heating elements and consumables.

Welcome to an open world

Benefit from a full access to 3D printing parameters and create your own automation functions within the system.

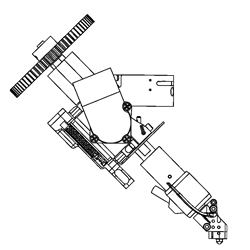

Tireless drivetrain for lasting quality

We selected trusted suppliers from demanding industry as aeronautics to supply our components.

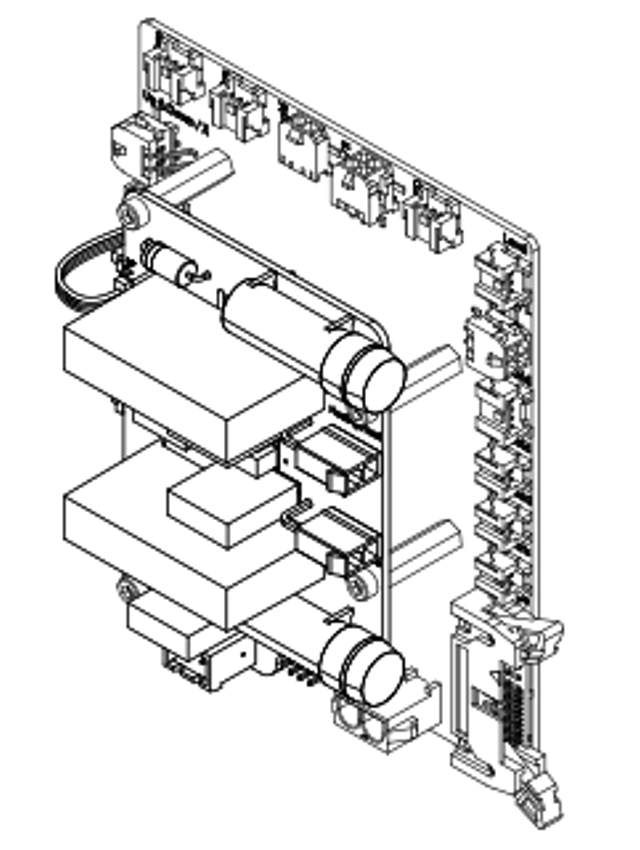

Reliable electronics at high temperature

A complete redesign of the electronics for greater control and ease of use in all conditions.

Robust mechanical architecture

for improved component durability and efficiency!

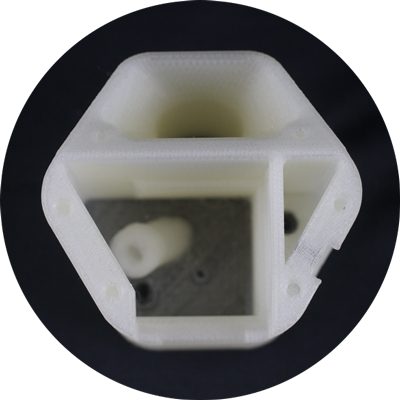

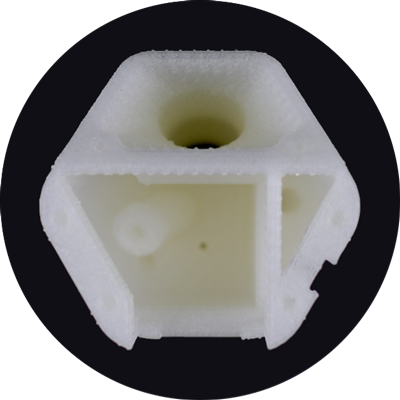

Inverted Delta

It is the best compromise between compacity, speed and accuracy. Coupled with ground guide rods for greater precision and strength.

High quality components

Specially-engineered equipment to meet industrial requirements and guarantee greater durability. Made and assembled in France

Performant electronic components and wiring for reliable control of the system!

Fast and efficient electronics

New electronics design for a reliable control of thermal stability and system movement.

Energy-efficient electronics deliverying high thermal stability at low electricity consumption.

Ready for high temperature

The most demanding materials require a high-temperature environment, and our electronic components are designed to operate even in the harshest conditions.

Adapt your surface finish

with new features

Activated input shaping

Achieve a smooth surface finish on your printed parts at any speed, even at high temperatures.

VS

Without input shaping

Vibrations aren’t compensated by the system so the part can present irregularities.

Adapt your configuration

to your applications

Specific extruders

pam o2 offers different extruders depending on material behavior.

The extruders are easy to replace, so you can quickly switch from one configuration to another.

Heating elements

Take advantage of various options to create the ideal environment for printing your material : heating room, radiant disc, heating cartridge.

Wide choice of consumables

Over the years we built up a varied catalogue of consumables to offer its users even more possibilities. Nozzle, building plate, adhesive...

We also develop accessories on request.

Benefit from increased productivity with more accurate control in high temperature environments!

The temperatures stabilize faster at system launch, allowing for less temperature oscillations and temperature overshoot.

A new HT extruder allows improved thermal continuity from the compression zone to the extrusion die.

Power consumption is reduced with optimized PID for all heating elements: extruders, build plate, room and radiant disk.

Focus on user experience!

Comfort in operation

Low noise system ready to operate where you need it, even in closed office. Moreover the pellets are easy to store and can be handled safely.

Safety

For ceramics and metals applications, no volatile powder is present. System can be operated without incomfortable personal protective equipment or costly installation.

Comfort in maintenance

System designed to allow self and easy maintenance by the user.

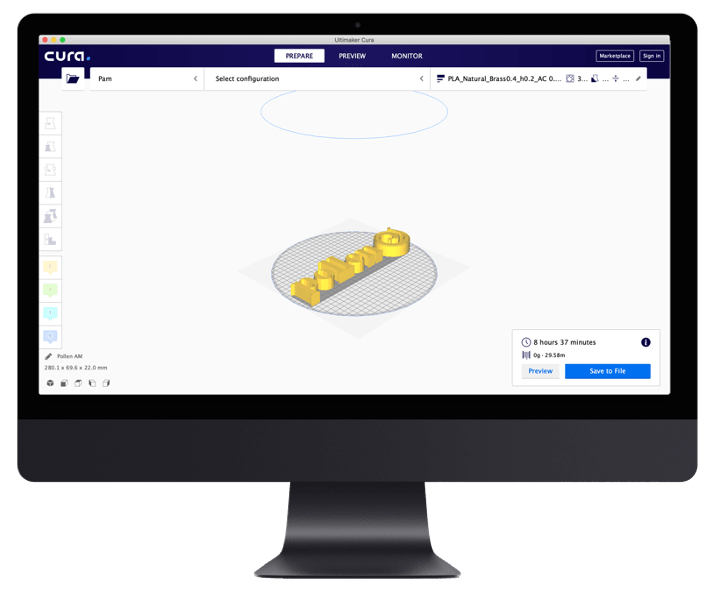

An open software ecosystem ready for customisation and scaling

Cura : the most popular slicing solution

pam o2 systems use Cura powered by Pollen AM. From easy to use to expert mode for a granular control of your printing, Cura is the essential slicer in 3D printing.

A wide variety of customizable macros accessible with one click

From intelligent "start-stop" system to perform maintenance, to scalable temperature control patterns specific to each extruder...

macros offer you a wide spectrum of possibilities!

Fully open source and modernized firmware

Benefit from new features to garantee quality printing even at high speed or collect data for analysis.

3D print at high speed without compromising on quality

3D Printing small and medium series of production with PAM has never been that fast!.

A batch of 24 grommets in TPU can be 3D printed on pam o2 in 4h33min compared to 9h on the previous generation of pam printers!

Build your own catalog

of material thanks to pellets

Material portfolio

Since our beginnings, we have developped hundreds of printing profile on various materials. Speed up your project by using printing profile developed by our engineers.

Your printing profile

We puts more than 10 years of experience in pellet printing at your service to provide you with the skills required to make you autonomous in your developments.

On demand printing profile

Let our experts develop your printing profile and be ready to run it on your system.

New API enables collection of production analysis data!

Monitor ongoing print jobs for a simplified remote production management and export parameters recorded during the printing process in .CSV format.

Runtime feature keeps track of the system and accessories operating times.

Meet pam o2

pellet 3D printers!

Discover pam o2 MC

Dedicated to metals and ceramics

Discover pam o2 HT

High temperatures performance parts

Discover pam o2

Wide variety of commodity materials

Newsletter

sign up for updates

We’ll never share your email address with anyone.

And you can opt out at any time. We promise.

© 2026 Pollen AM inc. All rights Reserved.