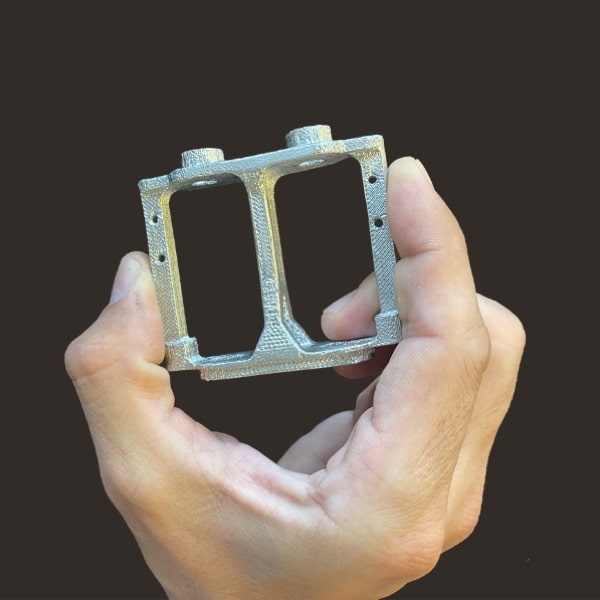

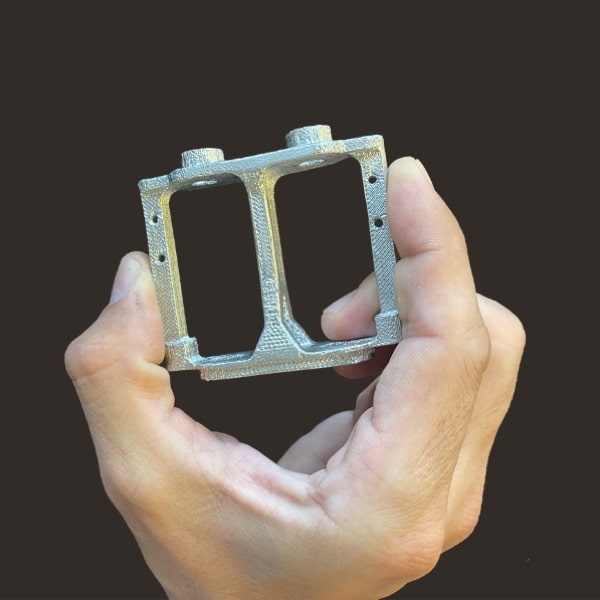

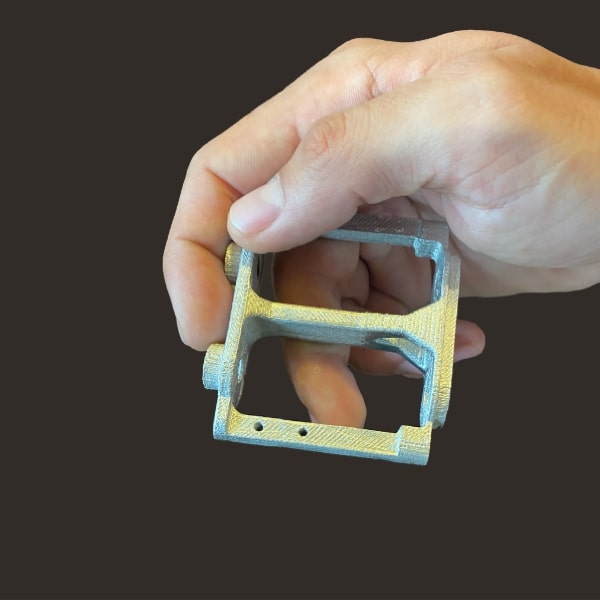

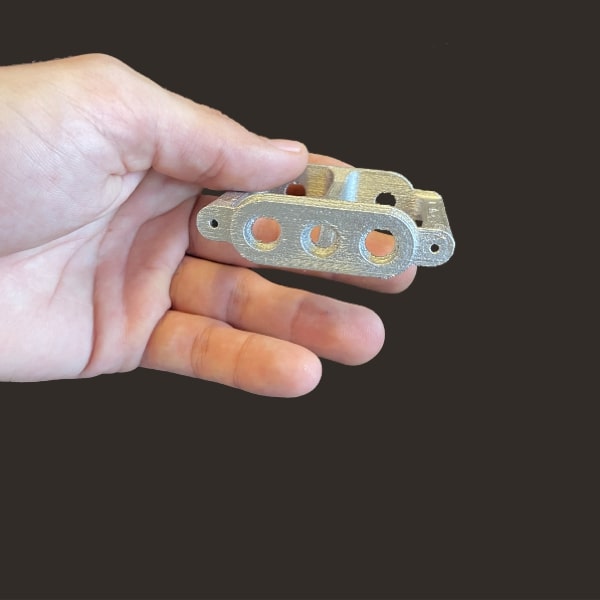

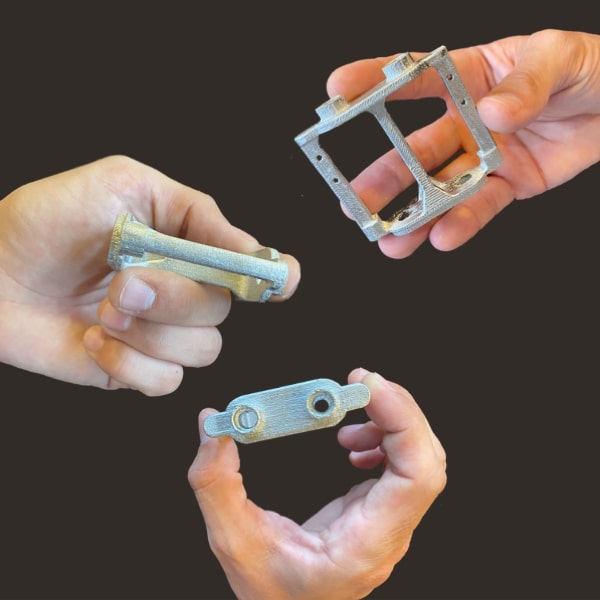

Stainless-steel Sheath Connector

Part presentation

Manufactured with pam o2, the 3D printer dedicated to metal and ceramic applications, this sheath connector is presented the sintered stage (after debinding & sintering steps), when the part is fully metallic, with lowest porosity.

The debinding and sintering operations have been made by Alliance MIM, the French MIM parts production industrial specialist.

This part serves both as a cable gland and as a fixing element.

It was 3D printed in a way not to need support structures, accelerating the production time and ensuring improved consistency of the MIM material.

Material information

- Supplier: Polymim

- Material: Stainless Steel

- Grade: 316L (1.4404)