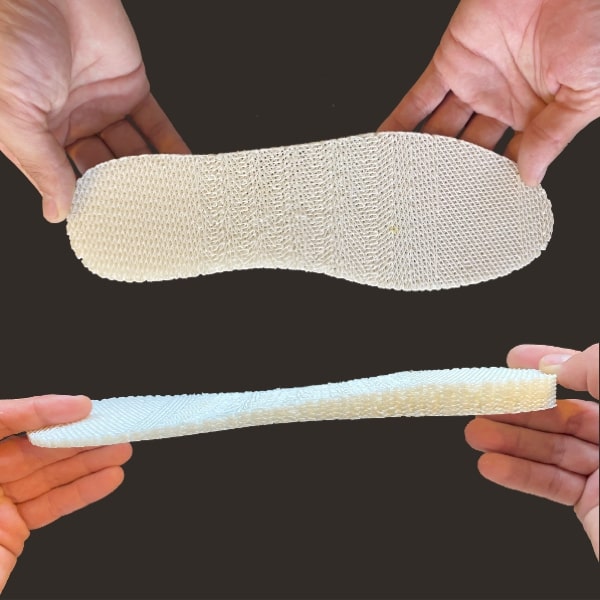

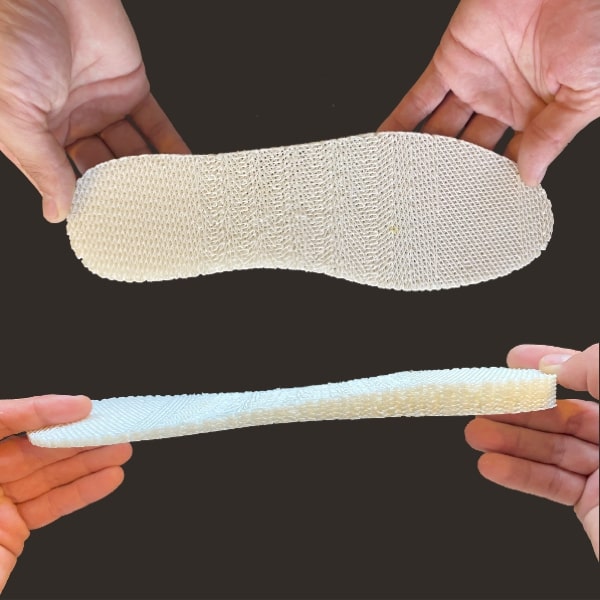

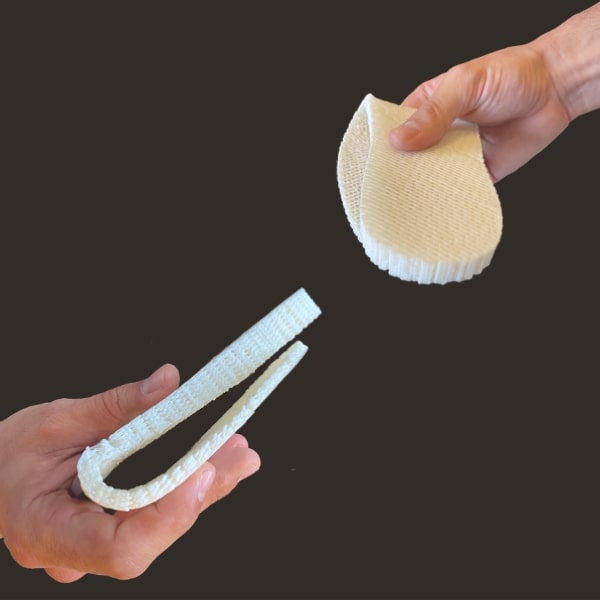

Lattice Insole

Part presentation

Manufactured with pam o2, this insole made of TPE 80 Shore A represented a speed challenge: being able to 3D print it in less than an hour.

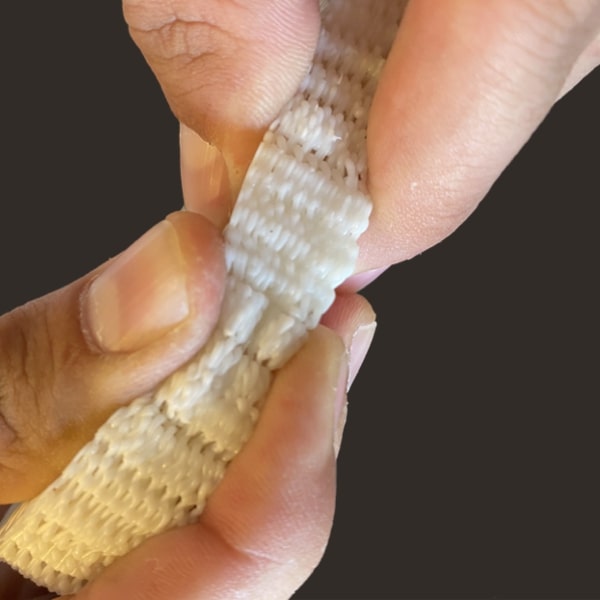

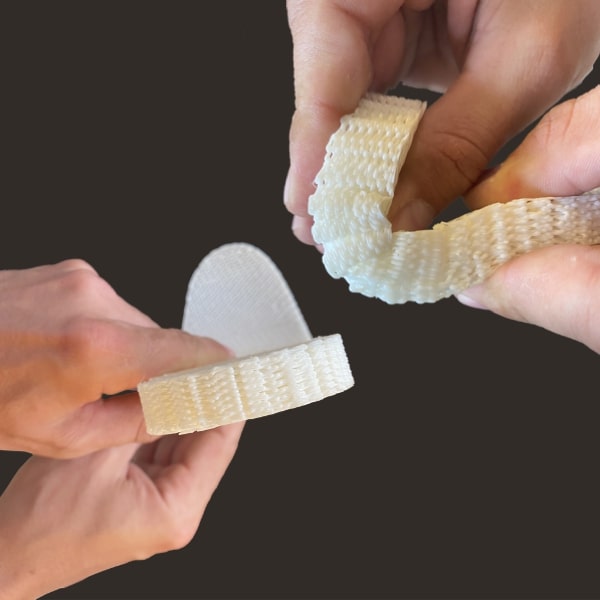

Part of an orthopaedic project, this print demonstrates the high flexibility of the insole conferred by both the material and the lattice structure. Furthermore, this illustrates that the speed of fabrication can be greatly optimized when a part is fully validated

Material information

- Supplier: DuPont

- Material: TPSiV

- Grade: 4000 80 A