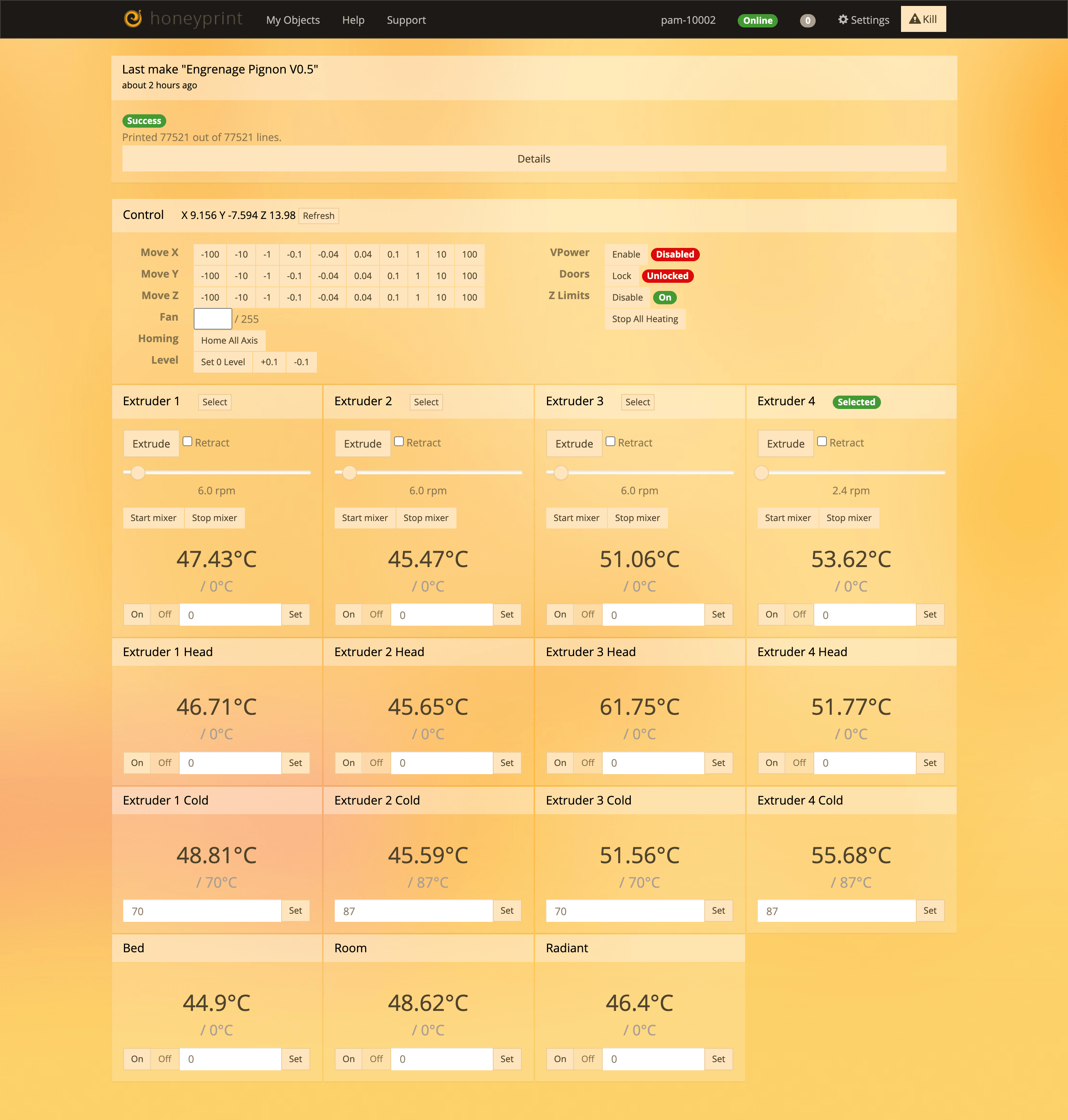

HoneyPrint

Manage & visualize your process.

Every Pam 3D printers are supplied with Honeyprint: its web-based control interface. It is accessible through its dedicated address.

Pam's 3D printers are thus consolable by any device, locally or remotely. It doesn't require an open internet connection and it is compatible with secure industrial networks.

This home page allows you to access all the main parameters of the machine and is divided into several categories:

- the general control panel;

- the extruders control panel;

- the accessories control panel;

- the terminal window.

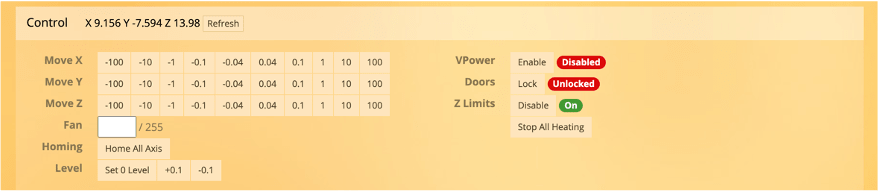

Control panel

This first control panel allows acting the basic parameters of the Pam printers. It is structured in two parts:

- Left side: buttons to move the construction plate, control the 3D printing cooling fans and the construction plate search function;

- Right side: power supply button (24V and 230V), door lock/unlock button, lighting control and heating elements stop button.

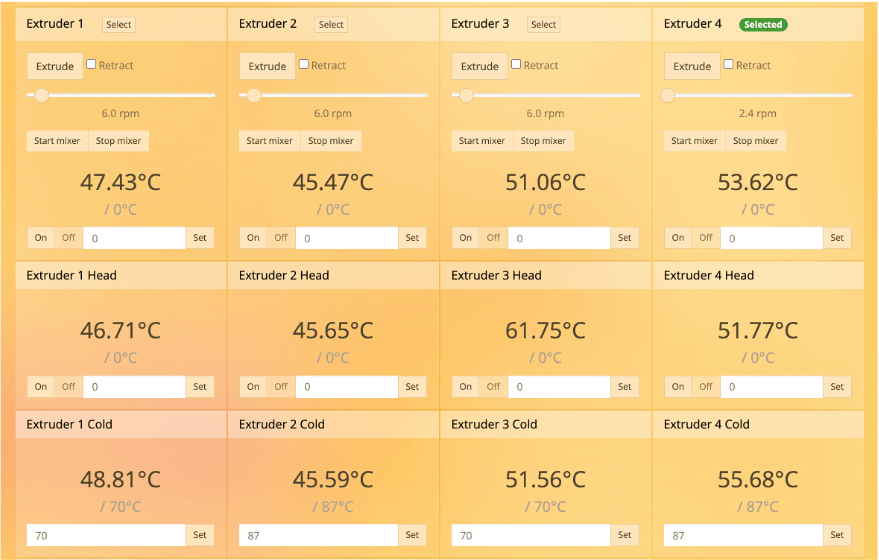

Extruders panel

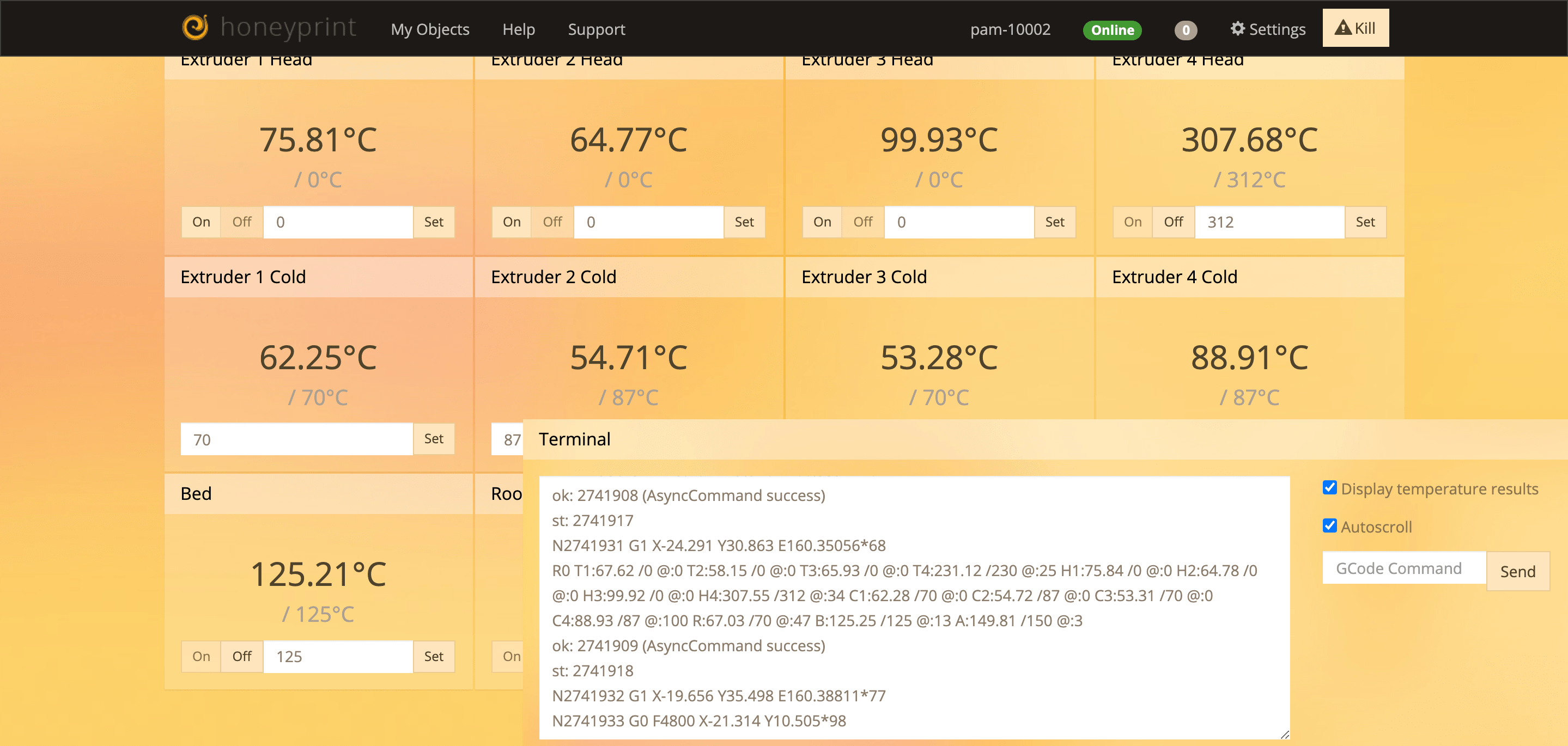

This second control panel is structured in columns, each one is dedicated to an extruder.

Every column is organized in three parts corresponding to the different extruder control points:

- "Extruder#", allows the user to select the working extruder and act on the body temperature and the extrusion speed;

- "Extruder# Head", allows the user to set the temperature of the extrusion die.

- "Extruder# Cold", allows the user to set the temperature of the cold point of the extruder (material inlet).

This part of the page is very useful when the operator uses his Pam 3D printer in "manual mode", i.e. to define his manufacturing process or when working on new materials.

During the printing cycles, this panel is used to have a view on the temperatures measured at each of the extruder control points.

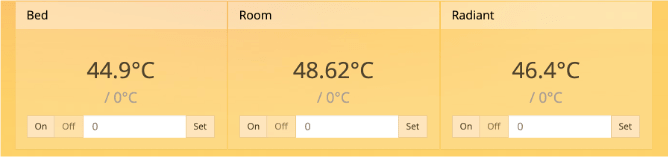

Accessories control panel

This third control panel allows acting on the different accessories of the Pam 3D printer.

Depending on the configuration of the system, the temperature of the printing build plate, the temperature of the heating chamber and the temperature of the radiant disc can be controlled.

Terminal window

At any time, a terminal window is accessible and allows the operator to fill in G.code command lines and act on the 3D printing job. It is possible, for example, to change temperatures on the fly or to modify the extrusion speed.